Toyota Sienna Service Manual: Installation

1. INSTALL FRONT SHOCK ABSORBER WITH COIL SPRING

(a) Install the front shock absorber with coil spring as shown in the illustration.

(b) Install the 3 nuts to the upper side of the front shock absorber with coil spring.

Torque: 80 N*m (816 kgf*cm, 59 ft.*lbf)

(c) Install the 2 bolts and 2 nuts to the lower side of the front shock absorber with coil spring.

Torque: 210 N*m (2,140 kgf*cm, 155 ft.*lbf)

NOTICE: When installing the bolt, hold the nut not to rotate.

(d) Fully tighten the lock nut.

Torque: 49 N*m (500 kgf*cm, 36 ft.*lbf)

(e) Install the front flexible hose No.1 and speed sensor front LH with the bolt.

Torque: 19 N*m (189 kgf*cm, 14 ft.*lbf)

2. INSTALL FRONT STABILIZER LINK ASSEMBLY LH

(a) Install the front stabilizer link assembly LH with the nut.

Torque: 74 N*m (755 kgf*cm, 55 ft.*lbf)

HINT: If the ball joint turns together with the nut, use a hexagon (6 mm) wrench to hold the stud.

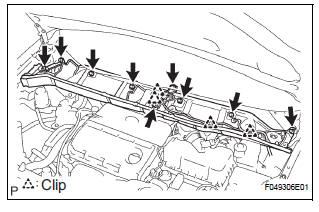

3. INSTALL COWL TOP PANEL SUB-ASSEMBLY OUTER FRONT

(a) Install the cowl top brace and cowl top panel subassembly outer front with the 9 bolts.

Torque: 7.5 N*m (76 kgf*cm, 66 in.*lbf) (b) Connect the wire harness to the cowl top panel subassembly outer front.

4. INSTALL WINDSHIELD WIPER MOTOR & LINK ASSEMBLY

HINT: (See page WW-3)

5. INSTALL FR WIPER ARM LH

HINT: (See page WW-3)

6. INSTALL FR WIPER ARM RH

HINT: (See page WW-3)

7. INSTALL FRONT WHEEL Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

8. INSPECT AND ADJUST FRONT WHEEL ALIGNMENT

HINT: (See page SP-4)

Reassembly

Reassembly

1. INSTALL SHOCK ABSORBER ASSEMBLY FRONT LH

2. INSTALL FRONT COIL SPRING INSULATOR LOWER

LH

(a) Install the front coil spring insulator lower LH onto

the shock absorber assembly front LH.

3. INST ...

Disposal

Disposal

1. DISPOSE OF SHOCK ABSORBER ASSEMBLY FRONT LH

HINT:

Dispose the RH side by the same procedures as the LH

side.

(a) Fully extend the shock absorber rod.

(b) Using a drill, make a hole in the cy ...

Other materials:

Front washer motor

ON-VEHICLE INSPECTION

1. INSPECT FRONT WASHER MOTOR

Operation Check

Pour the water into the washer jar with the

windshield washer motor and pump installed to

the washer jar assembly.

Connect the battery (+) to the terminal 1 of the

windshield washer motor and ...

Power Seat Motor Circuit

DESCRIPTION

When the power seat control switch is operated, a command signal is sent to

the position control ECU

and switch assembly (power seat control switch and ECU). The front power seat

switch then controls the

appropriate seat motor as needed. This memory system does not use a seat

po ...

Cold Start Ignition Timing Performance

DESCRIPTION

This monitor will run when the engine is started at -10 to 50°C (14 to 122°F)

of the engine coolant

temperature. The DTC will set after the engine idling for 13 seconds (2 trip

detection logic).

The DTC is designed to monitor the idle air control at cold start. When the

...