Toyota Sienna Service Manual: Installation

1. INSTALL BRAKE VACUUM CHECK VALVE ASSEMBLY

(a) Install the brake vacuum check valve assembly and check valve grommet to the brake booster assembly.

2. INSTALL BRAKE BOOSTER GASKET

(a) Install a new brake booster gasket to the brake booster with master cylinder.

3. INSTALL BRAKE MASTER CYLINDER ASSEMBLY

(a) Install the brake booster assembly with the 4 nuts.

Torque: 13 N*m (130 kgf*cm, 9 ft.*lbf) (b) Slide the clip and connect the brake master cylinder reservoir hose to the brake master cylinder union.

(c) Slide the clip and connect the vacuum hose from the brake vacuum check valve assembly.

4. INSTALL PUSH ROD PIN

(a) Install the push rod pin to the brake booster push rod.

5. INSTALL BRAKE LINE

(a) Install the front brake tube No. 1, front brake tube No. 2, front brake tube No. 3 and front brake tube No. 4.

Torque: 15 N*m (155 kgf*cm, 11 ft.*lbf) (b) Install the rear brake tube No. 1and rear brake tube No. 2.

Torque: 15 N*m (155 kgf*cm, 11 ft.*lbf)

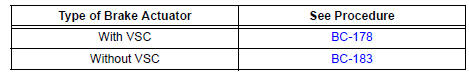

6. INSTALL BRAKE ACTUATOR ASSEMBLY (w/o VSC) SST 09023-00101

HINT: See page BC-184

7. INSTALL ABS & TRACTION ACTUATOR ASSEMBLY (w/ VSC) SST 09023-00101

HINT: See page BC-179.

8. INSTALL AIR CLEANER ASSEMBLY WITH HOSE

9. FILL RESERVOIR WITH BRAKE FLUID (See page BR- 3)

10. BLEED BRAKE MASTER CYLINDER (See page BR-3)

11. BLEED BRAKE LINE (See page BR-4)

12. BLEED BRAKE ACTUATOR (w/ VSC) (See page BR- 4)

13. CHECK FLUID LEVEL IN RESERVOIR (See page BR- 7)

14. CHECK BRAKE FLUID LEAKAGE

15. INSTALL INSTRUMENT PANEL SAFETY PAD INSERT SUB-ASSEMBLY NO. 1

(a) Install the instrument panel safety pad insert subassembly No. 1 with the 4 bolts.

16. INSTALL INSTRUMENT PANEL FINISH PANEL SUBASSEMBLY LOWER LH

(a) Install the instrument panel finish panel subassembly lower LH with the 2 bolts.

17. INSTALL COWL SIDE TRIM BOARD LH

(a) Install the cowl trim board plate LH with the nut.

18. INSTALL FRONT DOOR SCUFF PLATE LH

19. INSTALL COWL TOP PANEL SUB-ASSEMBLY OUTER FRONT

20. INSTALL FRONT WHEEL Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

21. INSPECT BRAKE PEDAL HEIGHT (See page BR-9)

22. CHECK BRAKE ACTUATOR WITH INTELLIGENT

TESTER

Inspection

Inspection

1. INSPECT BRAKE VACUUM CHECK VALVE ASSEMBLY

(a) Check the vacuum check valve.

(1) Slide the clip and disconnect the vacuum hose.

(2) Remove the vacuum check valve.

(3) Check that there ...

Front brake

Front brake

COMPONENTS

...

Other materials:

Diagnosis system

1. CHECK DLC3

The vehicle's ECU uses ISO 15765-4 for

communication protocol. The terminal arrangement

of the DLC3 complies with SAE J1962 and matches

the ISO 15765-4 format.

NOTICE:

*: Before measuring the resistance, leave the

vehicle as is for at least 1 minute and do not

...

DRL Relay Circuit

DESCRIPTION

The Multiplex network body ECU controls the DRL No.2 relay

WIRING DIAGRAM

INSPECTION PROCEDURE

1 PERFORM ACTIVE TEST BY INTELLIGENT TESTER

Connect the intelligent tester to DLC3.

Turn the ignition switch ON and push the intelligent

tester main switch ON.

Sel ...

Adjustment

1. VEHICLE PREPARATION FOR FOG LIGHT AIMING

Prepare the vehicle:

Ensure there is no damage or deformation to the

body around the fog lights.

Fill the fuel tank.

Make sure that the oil is filled to the specified

level.

Make sure that the coolant is fi ...