Toyota Sienna Service Manual: Installation

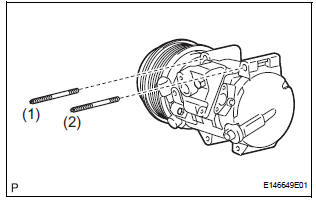

1. INSTALL COMPRESSOR AND MAGNETIC CLUTCH

(a) Using a "TORX" socket wrench (E8), install the compressor and magnetic clutch with the 2 stud bolts.

Torque: 10 N*m (102 kgf*cm, 7.4 ft.*lbf)

HINT: Tighten the stud bolts in the order shown in the illustration.

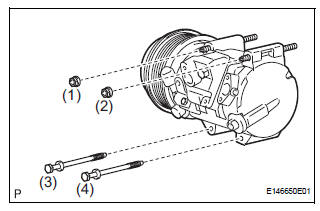

(b) Install the compressor and magnetic clutch with the 2 bolts and the 2 nuts.

Torque: 25 N*m (255 kgf*cm, 18 ft.*lbf)

HINT: Tighten the bolts and nuts in the order shown in the illustration.

(c) Connect the 2 clamps and wire harness.

(d) Connect the connector.

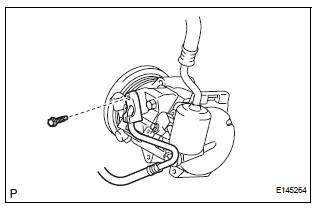

2. INSTALL SUCTION HOSE SUB-ASSEMBLY

(a) Remove the attached vinyl tape from the hose.

(b) Apply sufficient compressor oil to a new O-ring and the fitting surface of the compressor and magnetic clutch.

Compressor oil: ND-OIL 8 or equivalent

(c) Install the O-ring onto the suction hose subassembly.

(d) Install the suction hose sub-assembly onto the compressor and magnetic clutch with the bolt.

Torque: 5.4 N*m (55 kgf*cm, 48 in.*lbf)

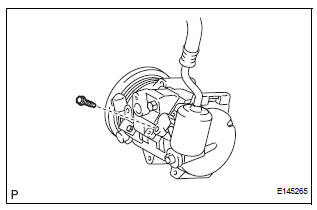

3. INSTALL DISCHARGE HOSE SUB-ASSEMBLY

(a) Remove the attached vinyl tape from the hose.

(b) Apply sufficient compressor oil to a new O-ring and the fitting surface of the compressor and magnetic clutch.

Compressor oil: ND-OIL 8 or equivalent

(c) Install the O-ring onto the discharge hose subassembly.

(d) Install the discharge hose sub-assembly onto the compressor and magnetic clutch with the bolt.

Torque: 5.4 N*m (55 kgf*cm, 48 in.*lbf)

4. INSTALL RADIATOR AND FAN ASSEMBLY

(See page CO-39)

5. INSTALL V-RIBBED BELT (See page EM-7)

6. INSTALL FRONT FENDER APRON SEAL RH (See page EM-62)

7. INSTALL FRONT WHEEL RH

8. CHARGE WITH REFRIGERANT (See page AC-173)

9. WARM UP ENGINE

10. INSPECT FOR REFRIGERANT LEAK (See page AC- 173)

Reassembly

Reassembly

1. INSTALL MAGNETIC CLUTCH ASSEMBLY

(a) Install the magnetic clutch stator while aligning the

protrusion on the stator with the notch on the air

compressor assembly as shown in the illustration ...

Condenser

Condenser

COMPONENTS

...

Other materials:

Inspection

1. INSPECT VENTILATION VALVE

(a) Install a clean hose to the ventilation valve.

(b) Check the ventilation valve operation.

(1) Blow air into the cylinder head side, and check

that air passes through easily.

NOTICE:

Do not suck air through the valve.

Petroleum substances i ...

Wrong Disc/ Disc cannot be Read

DTC 44-41 Wrong Disc

DTC 44-42 Disc cannot be Read

DESCRIPTION

DTC No.

DTC Detecting Condition

Trouble Area

44-41

An unsuitable disc is inserted

DVD

Television display assembly

44-42

The disc cannot be read.

IN ...

For driver side

ON-VEHICLE INSPECTION

1. INSPECT AIR MIX CONTROL SERVO MOTOR

(a) Remove the air mix control servo motor.

(b) Connect the positive (+) lead from the battery to

terminal 4 and negative (-) lead to terminal 5, then

check that the lever turns to "COOL" side smoothly.

(c) Connect ...