Toyota Sienna Service Manual: Installation

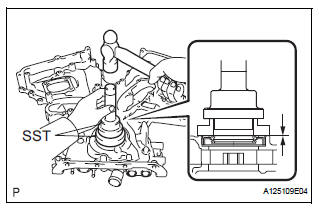

1. INSTALL TIMING CHAIN CASE OIL SEAL

(a) Using SST, tap in a new oil seal until its surface is flush with the timing chain case edge.

SST 09223-22010, 09506-35010

NOTICE:

|

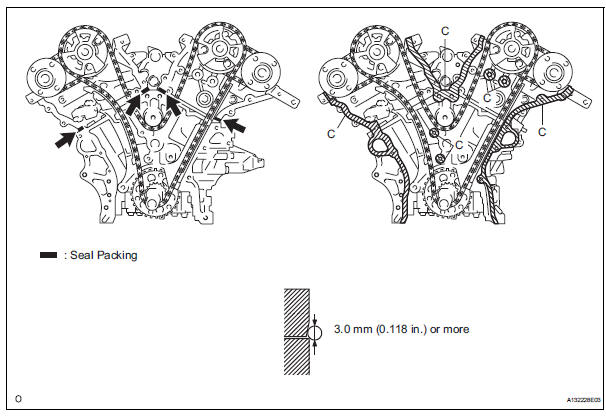

2. INSTALL TIMING CHAIN COVER SUB-ASSEMBLY

(a) Apply seal packing in a continuous line to the engine unit as shown in the following illustration.

Seal packing: Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent Seal diameter: 3.0 mm (0.118 in.)

NOTICE:

|

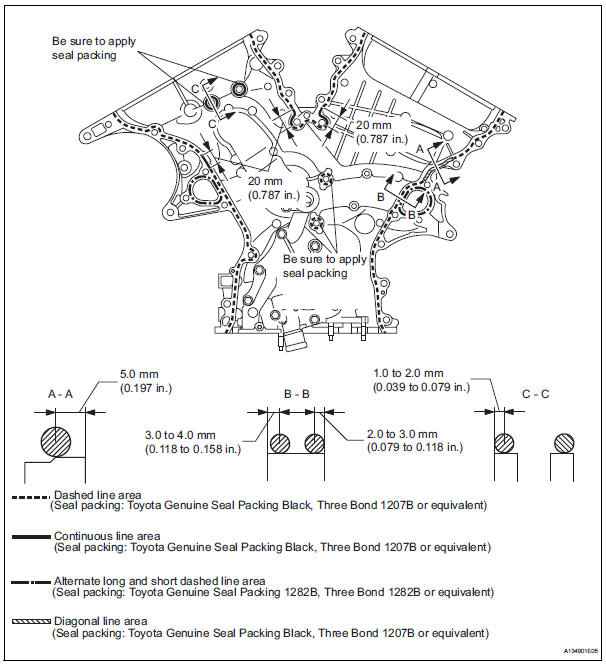

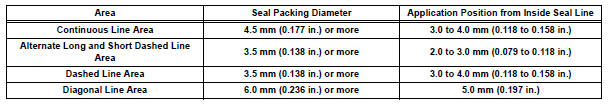

(b) Apply seal packing in a continuous line to the timing chain cover as shown in the following illustration.

Seal packing: Toyota Genuine Seal Packing Black, Three

Bond 1207B or equivalent

Toyota Genuine Seal Packing 1282B, Three

Bond 1282B or equivalent

NOTICE:

|

Apply seal packing as follows

(c) Install a new gasket.

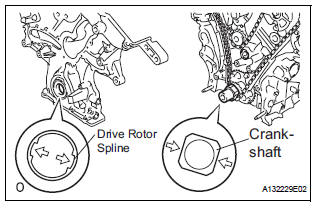

(d) Align the oil pump's drive rotor spline and the crankshaft as shown in the illustration. Install the spline and chain cover to the crankshaft.

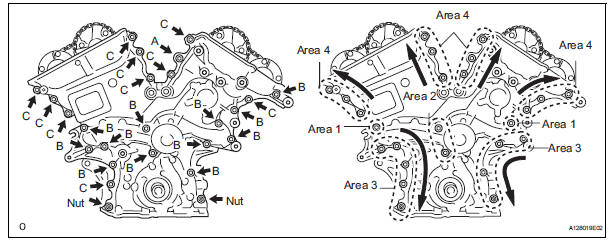

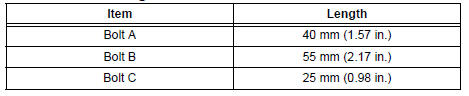

(e) Temporarily tighten the timing chain cover with the 23 bolts and 2 nuts.

Bolt length

| NOTICE: Make sure that there is no oil on the bolt threads. |

(f) Fully tighten the bolts in: Area 1 and Area 2.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf) (g) Fully tighten the bolts and nuts in: Area 3.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf) HINT: Tighten the bolts and nuts from top to bottom as shown in the illustration.

(h) Fully tighten the bolts in: Area 4.

Torque: Bolt A 43 N*m (438 kgf*cm, 32 ft.*lbf) Except bolt A 21 N*m (214 kgf*cm, 15 ft.*lbf)

HINT: Tighten the bolts from bottom to top as shown in the illustration.

3. INSTALL WATER INLET HOUSING (See page CO-13) 4. INSTALL OIL PAN SUB-ASSEMBLY (See page EM- 160) 5. INSTALL OIL STRAINER SUB-ASSEMBLY (See page EM-161) 6. INSTALL NO. 2 OIL PAN SUB-ASSEMBLY (See page EM-162) 7. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY (for Bank 1) (See page EM-163) 8. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY (for Bank 2) (See page EM-163) 9. INSTALL CRANKSHAFT PULLEY (See page EM-166) 10. INSTALL OIL COOLER PIPE

(a) Install a new gasket to the oil pan sub-assembly.

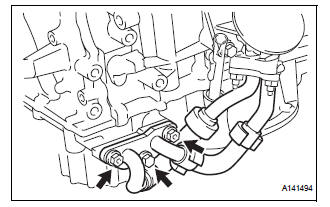

(b) Install the oil cooler pipe with the bolt and 2 nuts.

Torque: 21 N*m (214 kgf*cm, 16 ft.*lbf)

11. INSTALL NO. 1 OIL PIPE (See page EM-167) 12. INSTALL OIL PIPE (See page EM-168) 13. INSTALL OIL LEVEL GAUGE GUIDE SUBASSEMBLY (See page EM-48) 14. INSTALL ENGINE ASSEMBLY WITH TRANSAXLE

HINT: See page EM-44

Reassembly

Reassembly

1. INSTALL OIL PUMP COVER

(a) Coat the drive and driven rotors with engine oil and

place them into the timing chain cover with the

marks facing outward (oil pump cover side). Check

that the ro ...

Engine oil cooler

Engine oil cooler

Components

...

Other materials:

Diagnostic trouble code chart

1. DTCS FOR OCCUPANT CLASSIFICATION SYSTEM

If a trouble code is displayed during the DTC check,

check the circuit listed for the code in the table below

(proceed to the page listed for that circuit).

HINT:

When DTC B1150/23 is detected as a result of

troubleshooting for the airbag system, pe ...

Disassembly

1. REMOVE STOP LIGHT SWITCH ASSEMBLY

(a) Turn the stop light switch assembly

counterclockwise and remove the stop light switch

assembly.

(b) Remove the stop light switch mounting adjuster

from the brake pedal support sub-assembly.

2. REMOVE STOP LIGHT SWITCH CUSHION

(a) Remove the stop ligh ...

Rear washer motor

ON-VEHICLE INSPECTION

1. INSPECT REAR WASHER MOTOR

Pour the water into the washer jar with the rear

washer motor assembly installed to the washer jar

assembly.

Connect the battery (+) to the terminal 1 of the rear

washer motor assembly, the battery (-) to the

terminal ...