Toyota Sienna Service Manual: Installation

1. INSTALL FRONT DRIVE SHAFT ASSEMBLY LH

(a) Coat the spline of the inboard joint shaft assembly with ATF.

(b) Align the shaft splines and install the drive shaft assembly with a brass bar and hammer.

NOTICE:

- Set the snap ring with the opening side facing down.

- Be careful not to damage the drive shaft dust cover, boot and oil seal.

- Move the drive shaft assembly while keeping it level.

2. INSTALL FRONT DRIVE SHAFT ASSEMBLY RH (for 2WD)

(a) Using a screwdriver, install a new bearing bracket hole snap ring.

NOTICE: Do not damage the oil seal and boot.

(b) Install the bolt.

Torque: 32 N*m (330 kgf*cm, 24 ft.*lbf)

3. INSTALL FRONT DRIVE SHAFT ASSEMBLY RH (for 4WD)

HINT: Install the RH side using the same procedures as for the LH side.

NOTICE:

- Set the snap ring with the opening side facing downward.

- Be careful not to damage the transaxle case oil seal, inboard joint boot and drive shaft dust cover.

4. INSTALL FRONT AXLE ASSEMBLY LH

(a) Install the drive shaft assembly LH to the front axle assembly LH.

NOTICE:

- Be careful not to damage the outboard joint boot.

- Be careful not to damage the speed sensor rotor.

5. INSTALL NO. 1 FRONT SUSPENSION ARM SUBASSEMBLY LOWER LH

(a) Install the lower ball joint to the front suspension arm sub-assembly lower with the bolt and nuts.

Torque: 127 N*m (1,300 kgf*cm, 94 ft.*lbf)

6. INSTALL TIE ROD END SUB-ASSEMBLY LH

(a) Install the tie rod end to the steering knuckle with the nut.

Torque: 49 N*m (500 kgf*cm, 36 ft.*lbf) (b) Install a new cotter pin.

NOTICE: If the holes for the cotter pin are not aligned, tighten the nut up to 60° further.

7. INSTALL SPEED SENSOR FRONT LH

(a) Install the speed sensor to the steering knuckle with the bolt.

Torque: 8.0 N*m (82 kgf*cm, 71 in.*lbf)

NOTICE: Prevent foreign matter from adhering to the speed sensor.

(b) Install the flexible hose and the speed sensor to the shock absorber with the bolt and set the clip of sensor on knuckle.

Torque: 19 N*m (192 kgf*cm, 14 ft.*lbf)

NOTICE:

- Be careful not to damage the speed sensor.

- Prevent foreign matter from adhering to the speed sensor.

- Do not twist the sensor wire when installing the speed sensor.

8. INSTALL FRONT STABILIZER LINK ASSEMBLY LH

(a) Install the stabilizer link assembly LH with the nut.

Torque: 74 N*m (755 kgf*cm, 55 ft.*lbf)

HINT: If the ball joint turns together with nut. use a hexagon (6 mm) wrench to hold the stud.

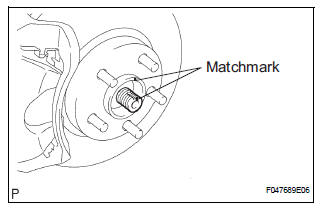

9. INSTALL FRONT AXLE HUB LH NUT

(a) Using a socket wrench (30 mm), install a new axle hub LH nut.

Torque: 294 N*m (3,000 kgf*cm, 217 ft.*lbf) (b) Using a chisel and hammer, stake the axle hub LH nut.

10. INSTALL FRONT WHEEL Torque: 103 N*m (1,050 kgf*cm, 76 ft.*lbf)

11. ADD AUTOMATIC TRANSAXLE FLUID

HINT:

- for U151E: (See page AX-123)

- for U151F: (See page AX-123)

12. ADD TRANSFER OIL (for 4WD)

HINT: (See page TF-3)

13. INSPECT AND ADJUST FRONT WHEEL ALIGNMENT

HINT: (See page SP-4)

14. CHECK ABS SPEED SENSOR SIGNAL

HINT:

- for ANTI-LOCK BRAKE SYSTEM: (See page BC-3)

- for VEHICLE STABILITY CONTROL SYSTEM: (See page BC-72)

Reassembly

Reassembly

1. INSTALL FRONT DRIVE SHAFT BEARING

(a) Using SST and a press, install a new front drive

shaft bearing.

SST 09710-30021 (09710-03141), 09527-10011

NOTICE:

Bearing should be completely instal ...

Rear drive shaft (for 4wd)

Rear drive shaft (for 4wd)

COMPONENTS

...

Other materials:

Removal

1. REMOVE FRONT WIPER ARM HEAD CAP

Using a small screwdriver, remove the 2 front wiper

arm covers.

HINT:

Tape up the screwdriver tip before use.

2. REMOVE FR WIPER ARM RH

Operate the wiper, and stop the windshield wiper

motor assembly to the automatic stop position.

...

Reassembly

1. INSTALL DIFFERENTIAL CASE SUB-ASSEMBLY NO.2

(a) Coat the front differential side gear thrust washer

No.1, front differential planetary ring gear, front

differential pinion No.2, front differential pinion thrust

washer No.2, front differential pinion shaft holder,

front differential pinio ...

Replacing light bulbs

Headlight low beams (halogen bulb)

For left side only: Open the fuse box cover.

Unplug the connector while

pushing the lock release.

Turn the bulb base counterclockwise.

Install a new light bulb.

Align the 3 tabs on the light bulb

with the mounting, and insert.

...