Toyota Sienna Service Manual: On-vehicle inspection

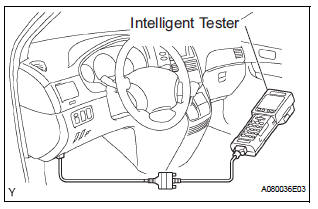

1. CONNECT INTELLIGENT TESTER

(a) Connect the intelligent tester to the DLC3.

(b) Start the engine and run at idle.

(c) Select the ACTIVE TEST mode on the intelligent tester.

HINT: Please refer to the intelligent tester operator's manual for further details.

2. INSPECT ACTUATOR MOTOR OPERATION

(a) With the motor relay on, check the actuator motor operation noise.

(b) Turn the motor relay off.

(c) Depress the brake pedal and hold it for approximately 15 seconds. Check that the brake pedal cannot be depressed.

(d) With the motor relay on, check that the pedal does not pulsate.

NOTICE: Do not keep the motor relay turned on for more than 5 seconds continuously. When operating it continuously, set an interval of more than 20 seconds.

(e) Turn the motor relay off and release the brake pedal.

3. INSPECT RIGHT FRONT WHEEL OPERATION

NOTICE: Never turn on the solenoids in a manner different to those described below.

(a) With the brake pedal depressed, perform the following operations.

(b) Turn the SFRH and SFRR solenoids on simultaneously, and check that the pedal cannot be depressed.

NOTICE: Do not keep the solenoid turned on for more than 10 seconds continuously. When operating it continuously, set an interval of more than 20 seconds.

(c) Turn the SFRH and SFRR solenoids off simultaneously, and check that the pedal can be depressed.

(d) Turn the motor relay on, and check that the pedal returns.

NOTICE: Do not keep the motor relay turned on for more than 5 seconds continuously. When operating it continuously, set an interval of more than 20 seconds.

(e) Turn the motor relay off and release the brake pedal.

4. INSPECT OTHER WHEEL OPERATION

(a) Using the same procedure, check the solenoids of the other wheels.

HINT: Left front wheel: SFLH, SFLR Right rear wheel: SRRH, SRRR Left rear wheel: SRLH, SRLR

Brake actuator (w/ vsc)

Brake actuator (w/ vsc)

Components

...

Removal

Removal

1. DRAIN BRAKE FLUID

NOTICE:

Wash brake fluid off immediately if it adheres to any

painted surface.

2. DISCONNECT BATTERY NEGATIVE TERMINAL

3. REMOVE AIR CLEANER ASSEMBLY WITH HOSE

4. REMOVE BRA ...

Other materials:

Receiver Error

DTC C2176/76 Receiver Error

DESCRIPTION

The signals are transmitted to the tire pressure warning antenna and receiver

on the body as radio waves

and then sent to the tire pressure warning ECU.

WIRING DIAGRAM

INSPECTION PROCEDURE

NOTICE:

When replacing the tire pressure warning EC ...

Installation

1. INSTALL NO. 2 REAR SEAT OUTER BELT ASSEMBLY

NOTICE:

Do not disassemble the retractor.

Check the degree of tilt when the No. 2 rear seat

outer belt assembly begins to lock the ELR.

Check that the belt does not lock within 15 of

tilt in all directions but that the be ...

Installation

1. INSTALL OCCUPANT CLASSIFICATION ECU

Check that the ignition switch is off.

Check that the negative battery (-) terminal is

disconnected.

CAUTION:

After disconnecting the negative battery

terminal, wait for at least 90 seconds before

starting the operation.

&nbs ...