Toyota Sienna Service Manual: On-vehicle inspection

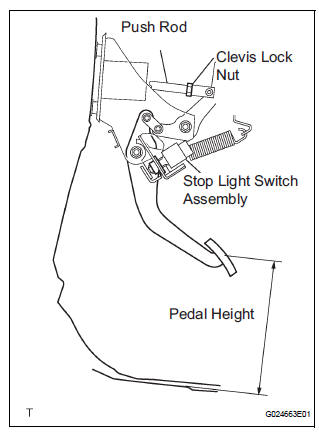

1. INSPECT BRAKE PEDAL HEIGHT

(a) Check the brake pedal height.

Pedal height from dash panel: 150.3 to 160.3 mm (5.917 to 6.311 in.)

NOTICE: Do not adjust the pedal height. Doing so by changing the push rod length will structurally change the pedal ratio.

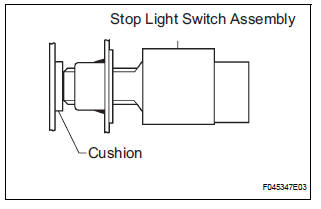

2. CHECK AND ADJUST STOP LIGHT SWITCH

(a) Disconnect the stop light switch assembly connector from the stop light switch assembly.

(b) Turn the stop light switch assembly counterclockwise and remove the stop light switch assembly.

(c) Insert the stop light switch assembly until the body hits the cushion.

NOTICE: When inserting the stop light switch assembly, support the pedal from behind so that the pedal is not pushed in.

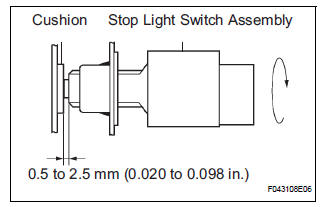

(d) Make a quarter turn clockwise to install the stop light switch assembly.

NOTICE:

- When inserting the stop light switch assembly, support the pedal from behind so that the pedal is not pushed in.

- The turning torque for installing the stop light switch assembly

Torque: 1.5 N*m (15 kgf*cm, 13 in.*lbf) or less

(e) Connect the stop light switch connector to the stop light switch assembly.

(f) Check the protrusion of the rod.

Protrusion of the rod: 0.5 to 2.5mm (0.020 to 0.098 in.)

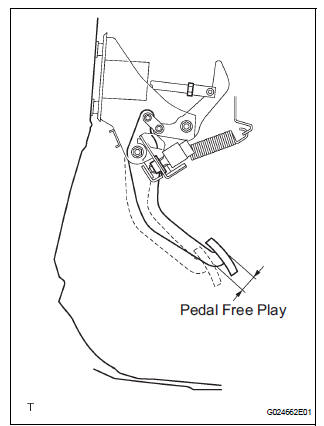

3. CHECK PEDAL FREE PLAY

(a) Stop the engine and depress the brake pedal several times until there is no more vacuum left in the booster.

(b) Push in the pedal until the beginning of the resistance is felt. Measure the distance, as shown.

Pedal free play: 1 to 6 mm (0.04 to 0.24 in.)

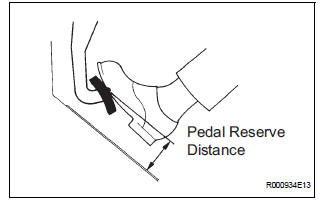

4. CHECK PEDAL RESERVE DISTANCE

(a) Release the parking brake pedal.

With the engine running, depress the pedal and measure the pedal reserve distance, as shown.

Pedal reserve distance from asphalt sheet at 490 N (50 kgf, 110 lbf): More than 52 mm (2.0 in.)

HINT: If the distance is out of the specification, troubleshoot the brake system.

Brake pedal

Brake pedal

Components

...

Removal

Removal

1. SEPARATE BATTERY NEGATIVE TERMINAL

2. REMOVE FRONT DOOR SCUFF PLATE LH

3. REMOVE COWL SIDE TRIM BOARD LH

4. REMOVE INSTRUMENT PANEL FINISH PANEL SUBASSEMBLY

LOWER LH

(a) Remove the 2 bolts and ...

Other materials:

Rear Airbag Sensor RH Circuit Malfunction

DTC B1154/38 Rear Airbag Sensor RH Circuit Malfunction

DESCRIPTION

The rear airbag sensor RH circuit consists of the center airbag sensor

assembly and rear airbag sensor

RH.

If the center airbag sensor assembly receives signals from the rear airbag

sensor RH, it judges whether or

not the ...

Disassembly

1. REMOVE NO. 2 FRONT AXLE INBOARD JOINT BOOT LH CLAMP

(a) Using pliers, remove the No. 2 front axle inboard

joint boot LH clamp, as shown in the illustration.

2. REMOVE FRONT AXLE INBOARD JOINT BOOT LH

CLAMP

(a) Remove the front axle inboard joint boot LH clamp

using the same procedures a ...

Installation

1. INSTALL CIGARETTE LIGHTER ASSEMBLY

Engage the 2 claws to install the cigarette lighter

assembly.

Install the cigarette lighter knob.

2. INSTALL CIGARETTE LIGHTER COVER

Engage the 2 claws to install the cigarette lighter

cover.

3. INSTALL INSTRUMENT CL ...