Toyota Sienna Service Manual: Open in One Side of CAN Branch Line

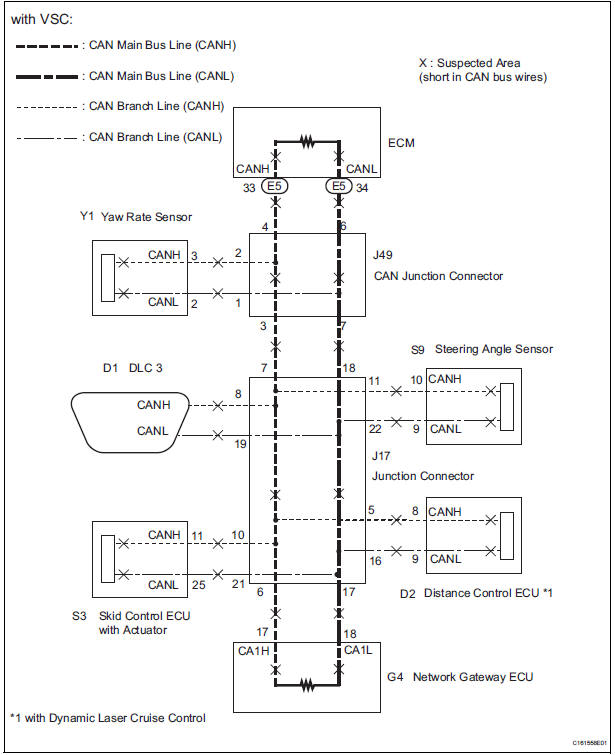

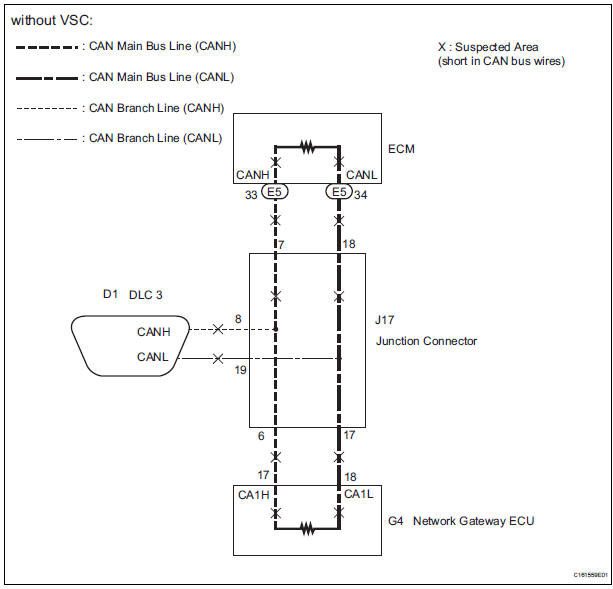

DESCRIPTION

If 2 or more ECUs and/or sensors do not appear on the intelligent tester "Communication Bus Check" screen, one side of the CAN branch wire may be open. (One side of the CAN-H [branch wire] / CAN-L [branch wire] of the ECU and/or sensor is open.)

|

Symptom |

Trouble Area |

| 2 or more ECUs and/or sensors do not appear on the intelligent tester "Communication Bus Check" screen. |

|

WIRING DIAGRAM

INSPECTION PROCEDURE

NOTICE:

- Turn the ignition switch off before measuring the resistances of CAN bus main wires and CAN bus branch wires.

- After the ignition switch is turned off, check that the key reminder warning system and light reminder warning system are not in operation.

- Before measuring the resistance, leave the vehicle as is for at least 1 minute and do not operate the ignition switch, any other switches, or the doors. If any doors need to be opened in order to check connectors, open the doors and leave them open.

HINT: Perform the following inspection for the ECUs (sensors) which are not displayed on the intelligent tester. If the malfunction cannot be identified, then perform the following inspections for the ECUs (sensors) connected to CAN communication.

1 CHECK FOR OPEN IN ONE SIDE OF CAN BRANCH WIRE

- Confirm the systems (ECUs and sensors), which use CAN communication, equipped on the vehicle. (See page CA-17)

- Using the intelligent tester, select and perform "Communication Bus Check". (See page CA-17) [*1]

- Disconnect the connectors from the ECUs or sensors that are not displayed on the screen. [*2]

- Check that only the ECUs and sensors from which the connectors were disconnected in the previous step are not displayed on the "Communication Bus Check" screen. [*3]

HINT: If any ECUs or sensors, other than those from which the connectors were disconnected in the previous step, are not displayed on the "Communication Bus Check" screen, reconnect the disconnected connectors and repeat the procedures [*1], [*2], and [*3].

(e) Perform the communication stop mode check for the ECUs and sensors which correspond to the disconnected connectors.

GO TO CORRESPONDING COMMUNICATION STOP MODE

Short to GND in CAN Bus Line

Short to GND in CAN Bus Line

DESCRIPTION

A short to GND is suspected in the CAN bus wire when the resistance between

terminals 4 (CG) and 6

(CANH), or terminals 4 (CG) and 14 (CANL) of the DLC3 is below 200 Ω.

...

Network gateway ECU

Network gateway ECU

COMPONENTS

REMOVAL

1. REMOVE FRONT DOOR SCUFF PLATE LH

2. REMOVE COWL SIDE TRIM BOARD LH

3. REMOVE INSTRUMENT PANEL FINISH PANEL

LOWER LH (See page IP-6)

4. REMOVE INSTRUMENT PANEL SAFETY PAD

...

Other materials:

Installing child restraints

Follow the child restraint system manufacturer’s instructions.

Firmly secure child restraints to the rear seats using the LATCH

anchors or a seat belt. Attach the top tether strap when installing

a child restraint.

The lap/shoulder belt can be used if your child restraint sy ...

Short to GND in Front Passenger Side Squib

2nd Step Circuit

DTC B1187/55 Short to GND in Front Passenger Side Squib

2nd Step Circuit

DESCRIPTION

The front passenger side squib 2nd step circuit consists of the center airbag

sensor assembly and the

front passenger airbag assembly.

The circuit instructs the SRS to deploy when deployment conditions are ...

Camshaft Position "A" - Timing Over

HINT:

If DTC P0011, P0012, P0021 or P0022 is present, check the VVT (Variable Valve

Timing) system.

DESCRIPTION

Refer to DTC P0010 (See page ES-75).

DTC No.

DTC Detection Condition

Trouble Area

P0011

P0021

Advanced cam timing:

With warm engine and engine spee ...