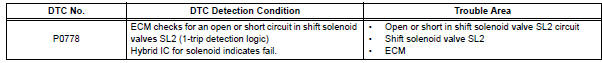

Toyota Sienna Service Manual: Pressure Control Solenoid "B" Electrical (Shift Solenoid Valve SL2)

DESCRIPTION

Shifting from 1st to 5th is performed in combination with "ON" and "OFF"

operation of the shift solenoid

valves SL1, SL2, SL3, S4 and SR which are controlled by the ECM. If an open or

short circuit occurs in

either of the shift solenoid valves, the ECM controls the remaining normal shift

solenoid valves to allow

the vehicle to be operated smoothly (Fail safe function).

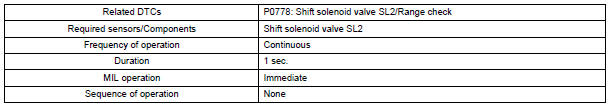

MONITOR DESCRIPTION

The ECM commands gear shifts by turning the shift solenoid valves "ON/OFF". When there is an open or short circuit in any shift solenoid valve circuit, the ECM detects the problem and illuminates the MIL and stores the DTC. And the ECM performs the fail-safe function and turns the other normal shift solenoid valves "ON/OFF" (In case of an open or short circuit, the ECM stops sending current to the circuit.) (See page AX-30).

MONITOR STRATEGY

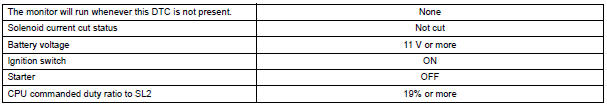

TYPICAL ENABLING CONDITIONS

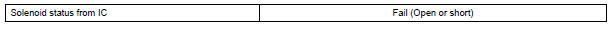

TYPICAL MALFUNCTION THRESHOLDS

COMPONENT OPERATING RANGE

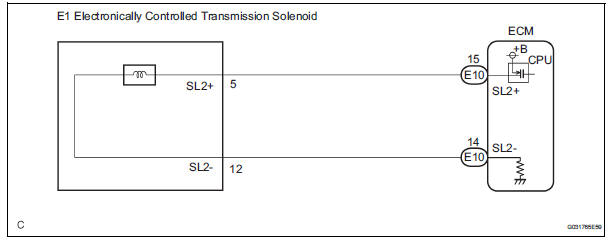

WIRING DIAGRAM

INSPECTION PROCEDURE

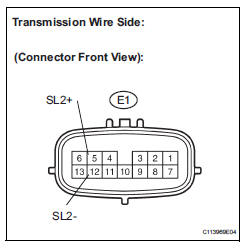

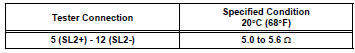

1 INSPECT TRANSMISSION WIRE (SL2)

(a) Disconnect the transmission wire connector from the transaxle.

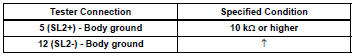

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

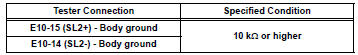

(c) Measure the resistance according to the value(s) in the table below.

OK:

Standard resistance (Check for short)

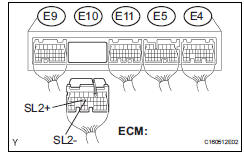

2 CHECK HARNESS AND CONNECTOR (TRANSMISSION WIRE - ECM)

(a) Connect the transmission wire connector to the transaxle.

(b) Disconnect the connector from the ECM.

(c) Measure the resistance according to the value(s) in the table below.

Standard resistance

(d) Measure the resistance according to the value(s) in the table below.

OK:

Standard resistance (Check for short)

REPLACE ECM

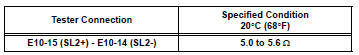

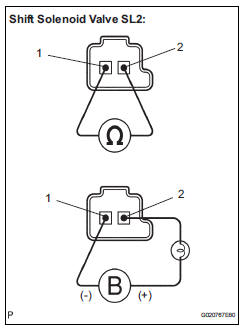

3 INSPECT SHIFT SOLENOID VALVE SL2

(a) Remove the shift solenoid valve SL2.

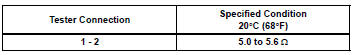

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

c) Connect the positive (+) lead with a 21 W bulb to terminal 2 and the negative (-) lead to terminal 1 of the solenoid valve connector, then check the movement of the valve.

OK: The solenoid makes an operating sound.

REPAIR OR REPLACE TRANSMISSION WIRE

Pressure Control Solenoid "B" Performance (Shift

Solenoid Valve SL2)

Pressure Control Solenoid "B" Performance (Shift

Solenoid Valve SL2)

SYSTEM DESCRIPTION

The ECM uses signals from the vehicle speed sensor to detect the actual gear

position (1st, 2nd, 3rd, 4th

or 5th gear).

Then the ECM compares the actual gear with the shi ...

Intermediate Shaft Speed Sensor "A"

Intermediate Shaft Speed Sensor "A"

DESCRIPTION

This sensor detects the rotation speed of the counter gear. By comparing the

counter gear speed signal

(NC) with the direct clutch speed sensor signal (NT), the ECM detects the shift

...

Other materials:

Installation

1. INSTALL STARTER ASSEMBLY

(a) Install the starter with the 2 bolts.

Torque: 37 N*m (380 kgf*cm, 26 ft.*lbf) for bolt

(b) Connect the starter connector.

(c) Install the terminal nut and cover the nut with the

cap.

Torque: 9.8 N*m (100 kgf*cm, 7 ft.*lbf) for nut

2. INSTALL NO. 1 ...

Side Airbag Sensor Assembly RH Circuit Malfunction

DTC B1140/32 Side Airbag Sensor Assembly RH Circuit Malfunction

DESCRIPTION

The side airbag sensor RH circuit consists of the center airbag sensor

assembly and side airbag sensor

RH.

If the center airbag sensor assembly receives signals from the side airbag

sensor RH, it judges whether or

...

Precaution

1. GENERAL PRECAUTION

When using the battery during inspection, do not

bring the positive and negative tester probes too

close to each other as a short circuit may occur.

PARTS LOCATION

SYSTEM DIAGRAM

1. SIGNAL COMMUNICATION TABLE

Driver Side Power Seat (w ...