Toyota Sienna Service Manual: Power Seat Motor Circuit

DESCRIPTION

When the power seat control switch is operated, a command signal is sent to the position control ECU and switch assembly (power seat control switch and ECU). The front power seat switch then controls the appropriate seat motor as needed. This memory system does not use a seat position sensor. The seat position is detected by counting pulses that are output when the motor turns. If there is no pulse output from the motor, the motor will stop operating. The position control ECU and switch assembly (power seat control switch and ECU) is designed so that any malfunction of the seat memory system will not interfere with manual seat control.

If the position control ECU and switch assembly (power seat control switch and ECU) detects a low motor speed, abnormal activity, or sudden motor current fluctuation, the system will stop the motor. If the motor operates continuously for 120 seconds or more, the system will stop the motor until the switch is turned on again.

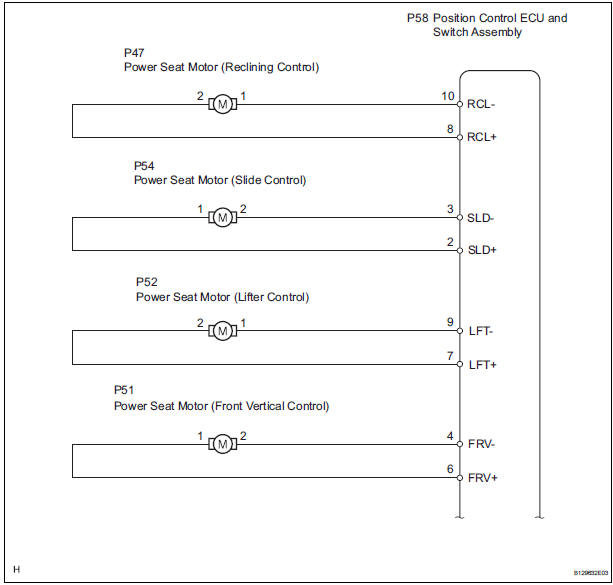

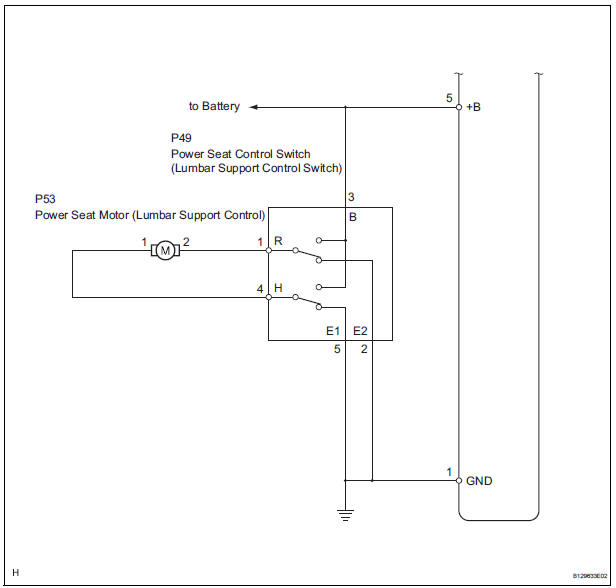

WIRING DIAGRAM

INSPECTION PROCEDURE

1 CHECK FRONT POWER SEAT OPERATION

- Check that each function of the power seat operates normally by using the front power seat switches.

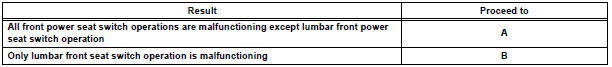

Result

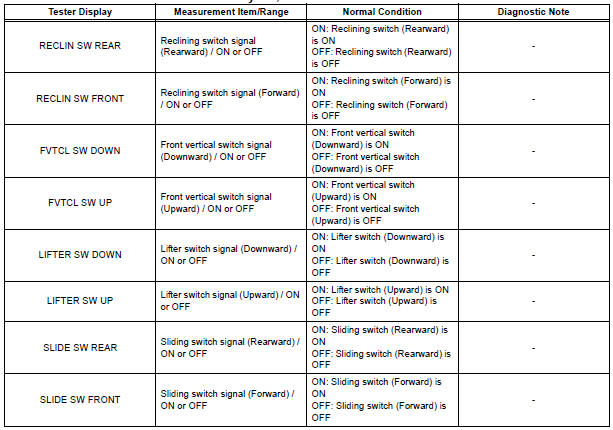

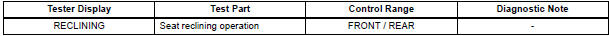

2 READ VALUE OF INTELLIGENT TESTER (FRONT POWER SEAT SWITCH)

- Check the DATA LIST for proper functioning of the front power seat switch.

Position control ECU & switch assembly LH, RH

OK: On tester screen, each item changes between ON and OFF according to above chart.

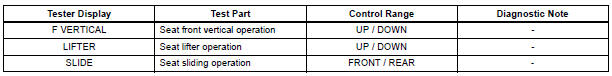

3 PERFORM ACTIVE TEST BY ACTIVE TEST USING INTELLIGENT TESTER (POWER SEAT MOTOR)

- Select the ACTIVE TEST, use the intelligent tester to generate a control command, and then check that the power seat motors operate.

Position control ECU & switch assembly (driver, passenger side)

OK: The power seat motors operate normally.

PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS TABLE

4 INSPECT FRONT SEAT ADJUSTER SUB-ASSEMBLY (POWER SEAT MOTOR)

- Inspect the power seat motor.

OK: The power seat motor operates.

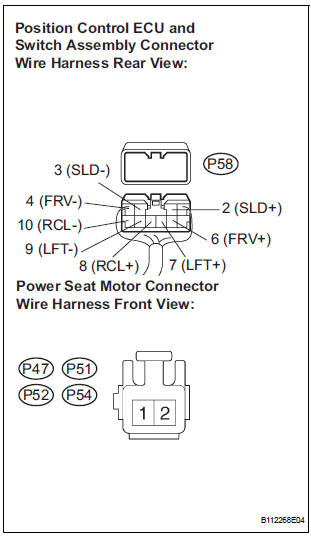

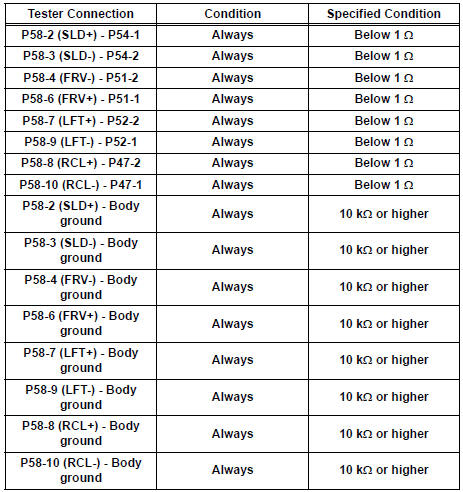

5 CHECK HARNESS AND CONNECTOR (POSITION CONTROL ECU AND SWITCH ASSEMBLY - POWER SEAT MOTOR)

- Disconnect the position control ECU and switch assembly connector and power seat motor connectors.

- Measure the resistance according to the value(s) in the table below.

Standard resistance

PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS TABLE

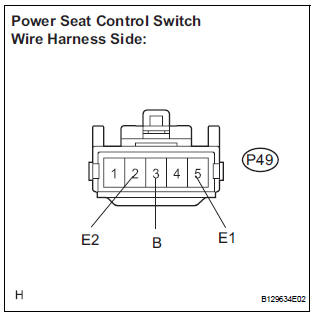

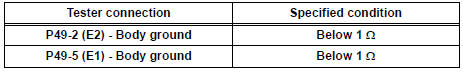

6 CHECK WIRE HARNESS (POWER SEAT CONTROL SWITCH - BATTERY AND BODY GROUND)

- Disconnect the P49 switch connector.

- Measure the voltage and resistance of the wire harness side connectors.

Standard voltage (Driver side)

Standard resistance (Driver side)

7 INSPECT POWER SEAT CONTROL SWITCH (LUMBER SUPPORT CONTROL)

- Inspect the power seat control switch

8 INSPECT FRONT SEAT ADJUSTER SUB-ASSEMBLY (POWER SEAT MOTOR)

- Inspect the power seat motor.

OK: The power seat motor operates

REPAIR OR REPLACE HARNESS OR CONNECTOR (POWER SEAT CONTROL SWITCH - POWER SEAT MOTOR)

On-vehicle inspection

On-vehicle inspection

1. CHECK POWER SEAT FUNCTION

Check the basic functions.

Operate the power seat switches and check the

following seat functions:

Sliding

Reclining

&nbs ...

Driving Position Memory Switch Circuit (w/ Memory)

Driving Position Memory Switch Circuit (w/ Memory)

DESCRIPTION

The seat memory switch sends signals to the outer mirror control ECU LH via

the multiplex

communication system to memorize a given seat position. This memory system does

not use a po ...

Other materials:

Adjustment procedure

Manual seat

Seat position adjustment lever

Seatback angle adjustment lever

Vertical height adjustment lever (driver’s side only)

Lumbar support adjustment switch (driver’s side only)*

*: If equipped

Power seat

Seat position adjustment switch

Seatback angle a ...

Disassembly

HINT:

Overhaul the RH side by the same procedures as these of

the LH side.

1. REMOVE REAR WHEEL

2. SEPARATE REAR DISC BRAKE CALIPER

ASSEMBLY LH

HINT:

Do not disconnect the flexible hose from the brake

caliper.

3. REMOVE REAR DISC

(a) Release the parking brake, and remove the rear

disc.

H ...

Problem symptoms table

POWER SLIDE DOOR SYSTEM

Symptom

Suspected Area

Power slide door LH does not operate when switch* is

pressed (* switch indicates satellite switch for power

slide door LH and power slide door control switch LH)

ECU-B fuse

Power slide door main switch ...