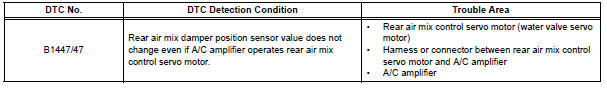

Toyota Sienna Service Manual: Rear Air Mix Damper Control Servo Motor Circuit

DESCRIPTION

The rear air mix control servo motor (water valve servo motor) is controlled by the A/C amplifier.

The rear air mix control servo motor moves the air mix damper by rotating

(normal, reverse) with electrical

power from the A/C amplifier.

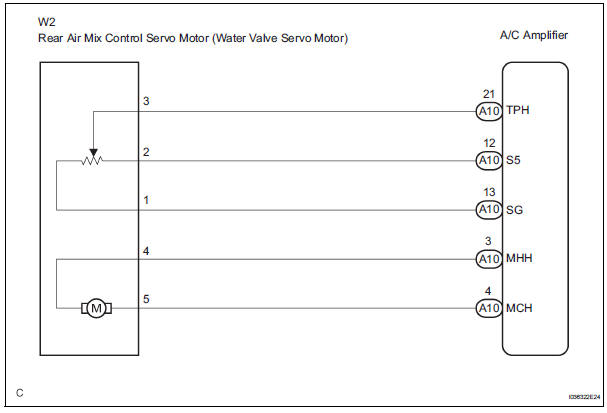

WIRING DIAGRAM

INSPECTION PROCEDURE

1 READ VALUE OF INTELLIGENT TESTER

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the intelligent tester main switch on.

(c) Select the items in the DATA LIST, and read the display on the intelligent tester.

DATA LIST / AIR CONDITIONER

OK: When the target position is "MAX. COOL" (0%), the actual opening angle is 19.0% or less.

When the target position is "MAX. HOT" (86.5%), the actual opening angle is 81.0% or more.

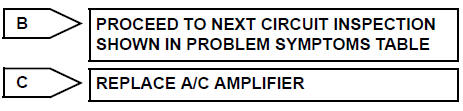

Result

2 PERFORM ACTIVE TEST BY INTELLIGENT TESTER

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the intelligent tester main switch on.

(c) Select the item below in the ACTIVE TEST and then check the air flow temperature by hand.

ACTIVE TEST / AIR CONDITIONER

OK: When the lever is moved to the "MAX. HOT" side, warm air comes out.

When the lever is moved to the "MAX. COOL" side, cool air comes out.

Result

3 PERFORM ACTUATOR CHECK

(a) Enter the actuator check mode (See page AC-15).

(b) Press the DEF switch and change to the step operation.

(c) Check the air flow temperature by hand.

OK: Air flow temperature changes in accordance with each display code.

Result

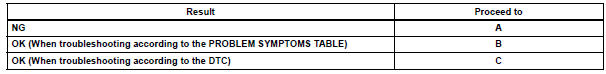

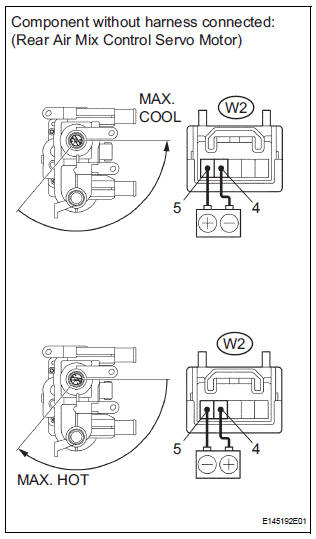

4 INSPECT REAR AIR MIX CONTROL SERVO MOTOR (WATER VALVE SERVO MOTOR)

(a) Remove the rear air mix control servo motor (water valve servo motor).

(b) Disconnect the connector from the rear air mix control servo motor.

(c) Connect the positive (+) lead from the battery to terminal 5 and the negative (-) lead to terminal 4, then check that the lever turns to the "MAX. COOL" position smoothly.

OK: Lever turns to "MAX. COOL" position smoothly.

(d) Connect the positive (+) lead from the battery to terminal 4 and the negative (-) lead to terminal 5, then check that the lever turns to the "MAX. HOT" position smoothly.

OK: Lever turns to "MAX. HOT" position smoothly.

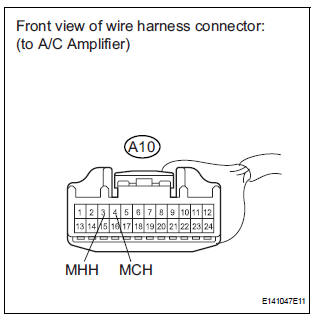

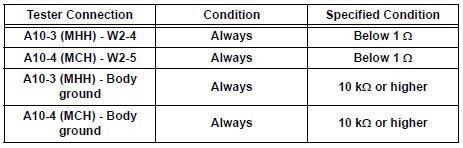

5 CHECK HARNESS AND CONNECTOR (REAR AIR MIX CONTROL SERVO MOTOR - A/C AMPLIFIER)

(a) Disconnect the connector from the A/C amplifier.

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

REPLACE A/C AMPLIFIER

Air Mix Damper Control Servo Motor Circuit (Driver Side)

Air Mix Damper Control Servo Motor Circuit (Driver Side)

DESCRIPTION

The air mix control servo motor (air mix damper servo sub-assembly) is

controlled by the A/C amplifier.

The air mix control servo motor moves the air mix damper by rotating (normal, ...

Rear Air Outlet Damper Control Servo Motor Circuit

Rear Air Outlet Damper Control Servo Motor Circuit

DESCRIPTION

This circuit turns the servo motor and changes each damper position by

receiving the signals from the A/

C amplifier.

The rear air outlet damper servo motor switches the air outlet ...

Other materials:

SRS Warning Light does not Come ON

DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

1 CHECK BATTERY

Measure the voltage of the battery.

Standard voltage:

11 to 14 V

2 CHECK CONNECTORS

Turn the ignition switch to the LOCK position.

Disconnect the negative (-) terminal cable from the

battery, and wait for at le ...

Reassembly

1. Install lower radiator tank

(a) After checking that there are no foreign objects in

the lock plate groove, install a new O-ring without

twisting it.

HINT:

When cleaning the lock plate groove, lightly rub it

with sandpaper without scratching it.

(b) Tap the lock plate with a plastic ...

Correct driving posture

Adjust the angle of the seatback so that you are sitting straight up and

so that you do not have to lean forward to steer.

Adjust the seat so that you can depress the pedals fully and so that

your arms bend slightly at the elbow when gripping the steering wheel.

Lock the head rest ...