Toyota Sienna Service Manual: Reassembly

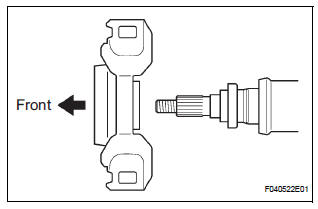

1. INSTALL CENTER SUPPORT BEARING ASSEMBLY NO.1

(a) Set the center support bearing assembly No. 1 (front) to the intermediate shaft, as shown in the illustration.

(b) Install a new washer to the intermediate shaft.

NOTICE: Be sure to install the bearing in the correct direction.

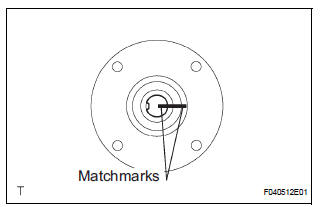

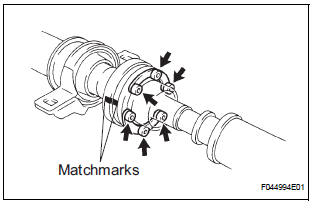

(c) Align the matchmarks on the front flange and shaft, and place the flange on the shaft.

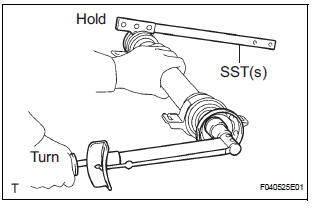

(d) Using SST(s) to hold the front flange, press the center support bearing assembly No. 1 (front) into the position by tightening down with a new nut and plate washer.

SST 09330-00021 Torque: 181 N*m (1,850 kgf*cm, 134 ft.*lbf)

(e) Loosen the nut.

(f) Torque the nut again.

Torque: 69 N*m (700 kgf*cm, 51 ft.*lbf)

(g) Using a chisel and a hammer, stake the nut.

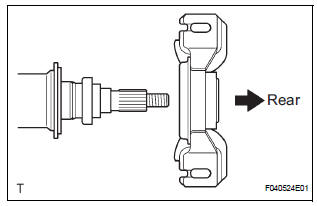

2. INSTALL CENTER SUPPORT BEARING ASSEMBLY NO.1

(a) Set the center support bearing assembly No. 1 (rear) on the shaft, as shown in the illustration.

(b) Install a new washer to the shaft.

NOTICE: Be sure to install the bearing in the correct direction.

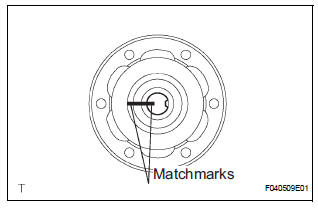

(c) Align the matchmarks on the rear flange and shaft, and place the flange on the shaft.

(d) Using SST(s) to hold the front flange, press the center support bearing assembly No. 1 (rear) into the position by tightening down with a new nut and plate washer.

SST 09330-00021 Torque: 181 N*m (1,850 kgf*cm, 134 ft.*lbf)

(e) Loosen the nut.

(f) Torque the nut again.

Torque: 69 N*m (700 kgf*cm, 51 ft.*lbf)

(g) Using a chisel and a hammer, stake the nut.

3. INSTALL INTERMEDIATE SHAFT

(a) Align the matchmarks on the intermediate shaft and rear propeller shaft assembly rear, then install the 2 washers and 6 bolts.

(b) Using a hexagon wrench (6 mm), loosely tighten the 6 bolts.

4. INSTALL PROPELLER SHAFT ASSEMBLY

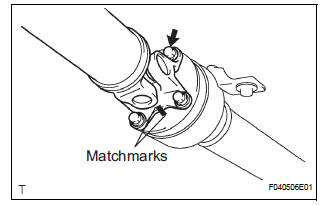

(a) Align the matchmarks on the propeller shaft assembly flange and front flange, and connect the shaft with the 4 bolts, washers and nuts.

Torque: 74 N*m (750 kgf*cm, 54 ft.*lbf)

(b) Check that each joint of the propeller shaft is facing in the correct direction, as shown in the illustration below.

Inspection

Inspection

1. INSPECT SPIDER BEARING

(a) Check that the spider bearing moves smoothly by

turning the flange.

(b) Check for the looseness around the joint by strongly

moving the flange in the axial and ...

Installation

Installation

1. INSTALL PROPELLER W/CENTER BEARING SHAFT ASSEMBLY

(a) Align the matchmarks on the propeller shaft

assembly rear flange and differential companion

flange, and connect the shaft with the 4 bol ...

Other materials:

Pressure Control Solenoid "C" Electrical (Shift

Solenoid Valve SL3)

DESCRIPTION

Shifting from 1st to 5th is performed in combination with "ON" and "OFF"

operation of the shift solenoid

valves SL1, SL2, SL3, S4 and SR which are controlled by the ECM. If an open or

short circuit occurs in

either of the shift solenoid valves, the ECM controls ...

Removal

1. REMOVE REAR WINDOW SIDE GARNISH

ASSEMBLY

2. REMOVE REAR DOOR WINDOW FRAME SUBASSEMBLY

3. REMOVE SIDE TRIM BOARD COVER REAR

4. REMOVE REAR DOOR TRIM BOARD SUBASSEMBLY

5. REMOVE REAR DOOR GLASS RUN

6. REMOVE SLIDE DOOR WINDOW ASSEMBLY

7. REMOVE REAR DOOR GLASS WEATHERSTRIP

Put pro ...

Mass or Volume Air Flow Circuit

DESCRIPTION

The Mass Air Flow (MAF) meter is a sensor that measures the amount of air

flowing through the throttle

valve. The ECM uses this information to determine the fuel injection time and to

provide appropriate airfuel

ratio. Inside the MAF meter, there is a heated platinum wire whic ...