Toyota Sienna Service Manual: Engine Coolant Temperature Circuit Range / Performance Problem

DESCRIPTION

Refer to DTC P0115 (See page ES-133).

MONITOR DESCRIPTION

The ECT sensor is used to monitor the ECT. The ECT sensor has a built-in thermistor with a resistance that varies according to the temperature of the engine coolant. When the ECT becomes low, the resistance of the thermistor increases. When the temperature becomes high, the resistance drops. These variations in the resistance are reflected in the voltage output from the ECT sensor.

The ECM monitors the sensor voltage and uses this value to calculate the ECT. If the sensor voltage output deviates from the normal operating range, the ECM interprets this deviation as a malfunction in the ECT sensor and sets the DTC.

Examples:

- Upon starting the engine, the ECT is between 35¬įC and 60¬įC (95¬įF and 140¬įF). If the ECT remains within 3¬įC (5.4¬įF) of the stating temperature after driving for 250 seconds, the DTC is set (2 trip detection logic).

- Upon starting the engine, the ECT is over 60¬įC (140¬įF). If the ECT remains within 1¬įC (1.8¬įF) of the starting temperature after driving for 250 seconds, the DTC is set (6 trip detection logic).

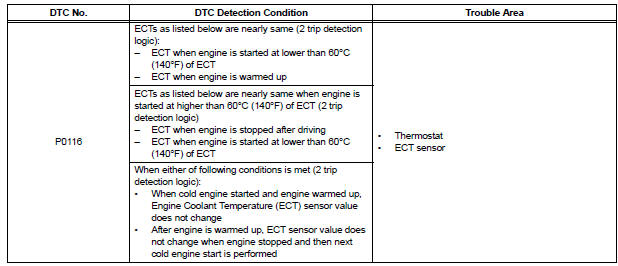

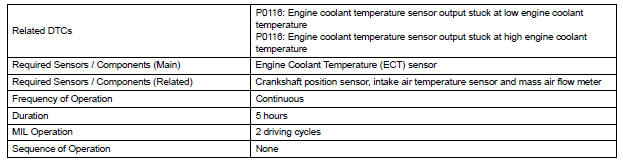

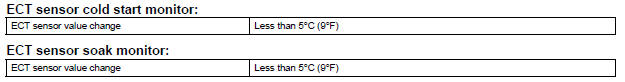

MONITOR STRATEGY

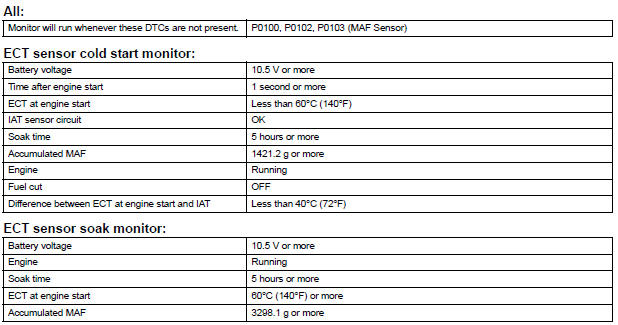

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

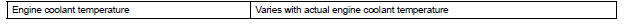

COMPONENT OPERATING RANGE

INSPECTION PROCEDURE

HINT:

- If any of DTC P0115, P0117, P0118 or P0125 are set simultaneously with DTC P0116, the ECT sensor may have an open or a short circuit. Troubleshoot those DTCs first.

- Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data can be helpful in determining whether the vehicle was running or stopped, whether the engine was warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the time of a malfunction.

1 CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P0166)

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position.

(c) Turn the tester on.

(d) Enter the following menus: DIAGNOSIS / ENHANCED II / DTC INFO / CURRENT CODES.

(e) Read the DTC.

Result

2 INSPECT THERMOSTAT

(a) Remove the thermostat (See page CO-16).

(b) Check the valve opening temperature of the thermostat.

Standard: 80 to 84¬įC (176 to 183¬įF)

HINT:

In addition to the above check, confirm that the valve is completely closed when the temperature is below the standard.

(c) Reinstall the thermostat (See page CO-17).

REPLACE ENGINE COOLANT TEMPERATURE SENSOR

Engine Coolant Temperature Circuit

Engine Coolant Temperature Circuit

DESCRIPTION

A thermistor is built into the Engine Coolant Temperature (ECT) sensor, of

which the resistance value

varies according to the ECT.

The structure of the sensor and its connection ...

Engine Coolant Temperature / Intake Air Temperature Correlation

Engine Coolant Temperature / Intake Air Temperature Correlation

DESCRIPTION

The ECM calculates the difference between the readings of the coolant

temperature sensor and intake air

temperature sensor. If the difference is greater than 20¬įC (68¬įF), the ECM ...

Other materials:

Short to GND in CAN Bus Line

DESCRIPTION

A short to GND is suspected in the CAN bus wire when the resistance between

terminals 4 (CG) and 6

(CANH), or terminals 4 (CG) and 14 (CANL) of the DLC3 is below 200 Ω.

Symptoms

Trouble Area

The resistance between terminals 6 (CANH) and 4 (CG), or ter ...

Washer Signal Circuit

DESCRIPTION

The distance control ECU detects washer operation. The cruise control will be

cancelled by the distance

control ECU if the windshield wipers operate in the HI or LO mode. By detecting

washer operation, the

distance control ECU allows the cruise control to continue even when the

...

Air conditioning controls

Adjusting the temperature setting

Turn the ‚ÄúTEMP‚ÄĚ dial clockwise to increase the temperature and

counterclockwise to decrease the temperature.

The ‚ÄúSYNC‚ÄĚ button

The air conditioning system switches between individual (indicator(

s) off) and simultaneous (indicators on) modes.

Whe ...