Toyota Sienna Service Manual: Removal

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

2. REMOVE ENGINE UNDER COVER NO.1

3. DRAIN AUTOMATIC TRANSAXLE FLUID

(a) Remove the drain plug and gasket, and drain the ATF.

(b) Install a new gasket and the drain plug.

Torque: 49 N*m (500 kgf*cm, 36 ft.*lbf)

4. REMOVE AUTOMATIC TRANSAXLE OIL PAN SUBASSEMBLY

(a) Remove the 18 bolts, oil pan and gasket.

| NOTICE: Some fluid will remain in the oil pan. Carefully remove the oil pan so that fluid remaining in the pan does not spill out. |

(b) Remove the 2 magnets from the oil pan.

(c) Examine particles in the pan.

(1) Collect any steel chips using the removed magnets. Look carefully at the chips and particles in the pan and on the magnets to see the type of wear which might be found in the transaxle.

Result: Steel (magnetic): Wear of the bearing, gear or plate Brass (non-magnetic): Wear of the bearing

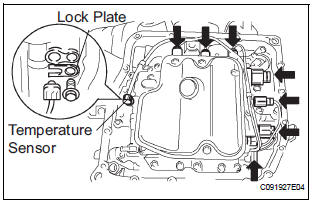

5. DISCONNECT TRANSMISSION WIRE

(a) Disconnect the 7 shift solenoid valve connectors.

(b) Remove the bolt and lock plate, and disconnect the ATF temperature sensor.

6. REMOVE TRANSMISSION WIRE

(a) Disconnect the transmission wire connector.

(b) Remove the bolt and transmission wire.

(c) Remove the O-ring from the transmission wire.

Transmission Wire

Transmission Wire

COMPONENTS

...

Installation

Installation

1. INSTALL TRANSMISSION WIRE

(a) Coat the O-ring of the transmission wire connector

with ATF and install it.

(b) Install the transmission wire with the bolt.

Torque: 5.4 N*m (55 kgf*cm, 48 ...

Other materials:

Adjustment

1. INSPECT SHIFT LEVER POSITION

(a) When shifting from P to R position only with ignition

switch ON and brake pedal, make sure that the

shifting lever moves smoothly and can be

moderately operated.

(b) When starting engine, make sure that the vehicle

moves forward when shifting from N to D p ...

Warning Buzzer Malfunction

DTC P1575 Warning Buzzer Malfunction

DESCRIPTION

The ABS & traction actuator (skid control ECU) receives an alarm demand

signal from the ECM and

operates the skid control buzzer. The buzzer sounds to warn that the distance

between the vehicle in front

and your own vehicle is decreasing.

...

Installation

1. INSTALL REAR DIFFERENTIAL SIDE GEAR SHAFT BOLT

(a) Install the bolt tightening the nut through the plate

washer.

2. INSTALL REAR DRIVE SHAFT ASSEMBLY LH

HINT:

(See page DS-26)

3. INSTALL REAR AXLE SHAFT NUT LH

HINT:

(See page DS-26)

4. INSTALL REAR SPEED SENSOR LH

HINT:

(See page D ...