Toyota Sienna Service Manual: Removal

1. REMOVE ENGINE ASSEMBLY WITH TRANSAXLE

HINT: (See page EM-26)

2. REMOVE FRONT DRIVE SHAFT ASSEMBLY LH

HINT: (See page DS-6)

3. REMOVE FRONT DRIVE SHAFT ASSEMBLY RH

HINT: (See page DS-6)

4. REMOVE TRANSMISSION CONTROL CABLE CLAMP

(a) Remove the bolt and the transmission control cable clamp.

5. REMOVE WIRE HARNESS CLAMP

(a) Disconnect the wire harnesses from the clamp.

(b) Remove the 3 bolts and 2 clamps.

6. DISCONNECT WIRE HARNESS

(a) Remove the bolt and disconnect the wire harness.

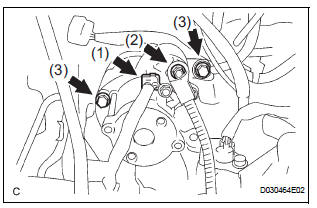

7. REMOVE STARTER ASSEMBLY

(a) Disconnect the connector (1).

(b) Remove the nut (2) and disconnect the starter wire.

(c) Remove the 2 bolts (3) and starter assembly.

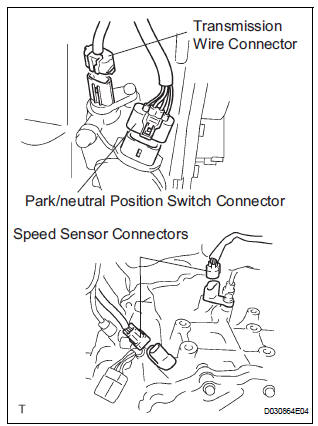

8. DISCONNECT CONNECTORS

(a) Disconnect the transmission wire connector.

(b) Disconnect the park/neutral position switch connector.

(c) Disconnect the 2 speed sensor connectors.

9. REMOVE TRANSMISSION CONTROL CABLE BRACKET NO.1

(a) Remove the bolt and automatic transmission oil cooler tube clamp.

(b) Remove the 2 bolts and transmission control cable bracket No.1.

10. REMOVE TRANSMISSION OIL FILLER TUBE SUBASSEMBLY

(a) Remove the ATF level gauge.

(b) Disconnect the wire harnesses 2 clamps from the oil filler tube.

(c) Remove the 2 bolts and oil filler tube.

(d) Remove the O-ring from the oil filler tube.

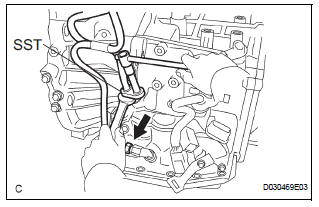

11. REMOVE OIL COOLER INLET TUBE NO.1

(a) Using SST and a wrench, disconnect the oil cooler inlet tube No.1.

SST 09023-12701

12. REMOVE OIL COOLER OUTLET TUBE NO.1

(a) Using SST and a wrench, disconnect the oil cooler outlet tube No.1.

SST 09023-12701

13. REMOVE ENGINE MOUNTING BRACKET FRONT

(a) Remove the 3 bolts and engine mounting bracket front.

14. REMOVE AUTOMATIC TRANSAXLE ASSEMBLY

(a) Remove the 2 bolts and flywheel housing under cover.

(b) Turn the crankshaft to gain access and remove the 6 bolts while holding the crankshaft pulley bolt with a wrench.

HINT: There will be one green colored bolt.

(c) Remove the 10 bolts.

(d) Separate and remove the automatic transaxle.

15. REMOVE TORQUE CONVERTER CLUTCH ASSEMBLY

16. INSPECT TORQUE CONVERTER CLUTCH ASSEMBLY

HINT: (See page AX-170)

Automatic transaxle assembly

Automatic transaxle assembly

Components

...

Installation

Installation

1. Install torque converter clutch assembly

(a) Install the torque converter clutch to the automatic

transaxle.

(b) Using vernier calipers and a straight edge, measure

the dimension "A& ...

Other materials:

Lock Switch Circuit

DESCRIPTION

Each of the left and right seats has lock switches that detect the lock

condition of the seat legs to the floor

when the seat is in the original or folded-down state. If any of the lock

switches detect an unlock condition,

the 3rd SEAT indicator on the combination meter will come ...

Road test

1. PROBLEM SYMPTOM CONFIRMATION

(a) Based on the result of the customer problem

analysis, try to reproduce the symptoms. If the

problem is that the transaxle does not shift up, shift

down, or the shift point is too high or too low,

conduct the following road test referring to the

automatic shi ...

Inspection

1. INSPECT HEATED OXYGEN SENSOR (for Bank 1

Sensor 2)

(a) Measure the resistance of the sensor.

Standard resistance

If the resistance is not as specified, replace the

sensor.

2. INSPECT HEATED OXYGEN SENSOR (for Bank 2

Sensor 2)

(a) Measure the resistance of the sensor.

Standard r ...