Toyota Sienna Service Manual: Throttle Actuator Control System

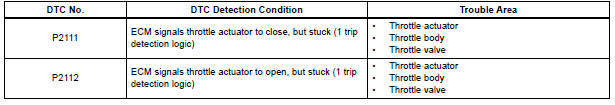

DTC P2111 Throttle Actuator Control System - Stuck Open

DTC P2112 Throttle Actuator Control System - Stuck Closed

DESCRIPTION

The throttle actuator is operated by the ECM, and opens and closes the throttle valve using the gears.

The opening angle of the throttle valve is detected by the Throttle Position (TP) sensor, which is mounted on the throttle body. The TP sensor provides feedback to the ECM so that it can control the throttle actuator and the throttle valve appropriately in response to driver inputs.

HINT: This ETCS (Electronic Throttle Control System) does not use a throttle cable.

MONITOR DESCRIPTION

The ECM determines that there is a malfunction in the ETCS when the throttle valve remains at the fixed angle despite a high drive current from the ECM. The ECM illuminates the MIL and sets a DTC.

If the malfunction is not repaired successfully, a DTC is set when the accelerator pedal is fully depressed and released quickly (to fully open and close the throttle valve) after the engine is next started.

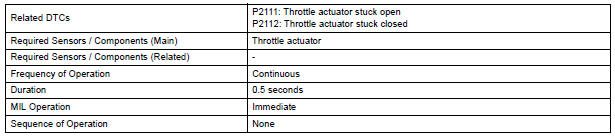

MONITOR STRATEGY

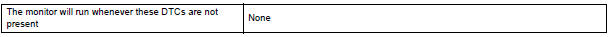

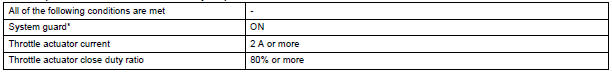

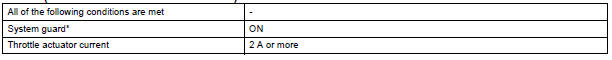

TYPICAL ENABLING CONDITIONS

All:

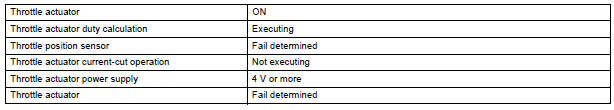

P2111 (Throttle actuator stuck open):

P2112 (Throttle actuator stuck closed):

*: System guard set when following conditions met

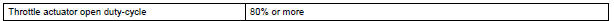

TYPICAL MALFUNCTION THRESHOLDS

P2111 (Throttle actuator stuck open):

P2112 (Throttle actuator stuck closed):

FAIL-SAFE

When either of these DTCs, as well as other DTCs relating to ETCS (Electronic Throttle Control System) malfunctions, is set, the ECM enters fail-safe mode. During fail-safe mode, the ECM cuts the current to the throttle actuator off, and the throttle valve is returned to a 6 throttle angle by the return spring. The ECM then adjusts the engine output by controlling the fuel injection (intermittent fuel-cut) and ignition timing, in accordance with the accelerator pedal opening angle, to allow the vehicle to continue at a minimal speed.

If the accelerator pedal is depressed slowly, the vehicle can be driven slowly.

Fail-safe mode continues until a pass condition is detected, and the ignition switch is then turned off.

WIRING DIAGRAM

Refer to DTC P2102.

INSPECTION PROCEDURE

HINT: Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data can be helpful in determining whether the vehicle was running or stopped, whether the engine was warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the time of a malfunction.

1 CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P2111 OR P2112)

- Connect the intelligent tester to the DLC3.

- Turn the ignition switch to the ON position.

- Turn the tester on.

- Select the following menu items: DIAGNOSIS / ENHANCED OBD II / DTC INFO / CURRENT CODES.

- Read the DTCs.

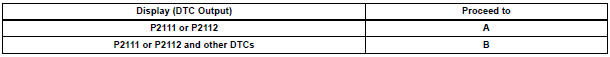

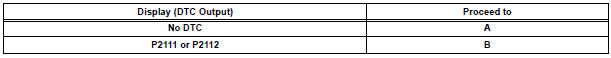

Result

HINT: If any DTCs other than P2111 or P2112 are output, troubleshoot those DTCs first.

2 INSPECT THROTTLE BODY (VISUALLY CHECK THROTTLE VALVE)

- Check for contamination between the throttle valve and the housing. If necessary, clean the throttle body. And check that the throttle valve moves smoothly.

OK: Throttle valve is not contaminated with foreign objects and moves smoothly.

3 CHECK WHETHER DTC OUTPUT RECURS (DTC P2111 OR P2112)

- Connect the intelligent tester to the DLC3.

- Turn the ignition switch to the ON position.

- Turn the tester on.

- Clear the DTCs.

- Start the engine, and fully depress and release the accelerator pedal quickly (to fully open and close the throttle valve).

- Select the following menu items: DIAGNOSIS / ENHANCED OBD II / DTC INFO / CURRENT CODES.

- Read the DTCs.

Result

CHECK FOR INTERMITTENT PROBLEMS

Throttle Actuator Control Motor Circuit

Throttle Actuator Control Motor Circuit

DTC P2102 Throttle Actuator Control Motor Circuit Low

DTC P2103 Throttle Actuator Control Motor Circuit High

DESCRIPTION

The throttle actuator is operated by the ECM and opens and closes the

thro ...

Throttle Actuator Control Motor Current Range

/ Performance

Throttle Actuator Control Motor Current Range

/ Performance

DTC P2118 Throttle Actuator Control Motor Current Range

/ Performance

DESCRIPTION

The ETCS (Electronic Throttle Control System) has a dedicated power supply

circuit. The voltage (+BM)

is monitor ...

Other materials:

Problem symptoms table

SLIDING ROOF SYSTEM

Symptom

Suspected area

AUTO function does not operate

Sliding roof motor assembly

Sliding roof system does not operate

ECU-IG fuse

S/ Roof fuse

IG1 relay

Sliding roof housing assembly

Sliding roof motor switc ...

Air Intake Control Circuit

DESCRIPTION

The air cleaner is equipped with two inlets, one of which is opened or closed

by the Air Intake Control

Valve (AICV). This system reduces intake noise and increases engine power at

low-to-high engine speed

range.

When the engine is operating in the low-to-mid speed range, this ...

Bluetooth Module Initialization Failed

DTC 57-47 Bluetooth Module Initialization Failed

DESCRIPTION

DTC No.

DTC Detection Condition

Trouble Area

57-47

Bluetooth module is not installed.

Problem with Bluetooth module

Problem in communication line to Bluetooth module

...