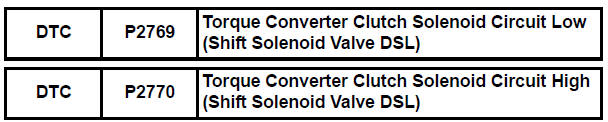

Toyota Sienna Service Manual: Torque Converter Clutch Solenoid Circuit

DESCRIPTION

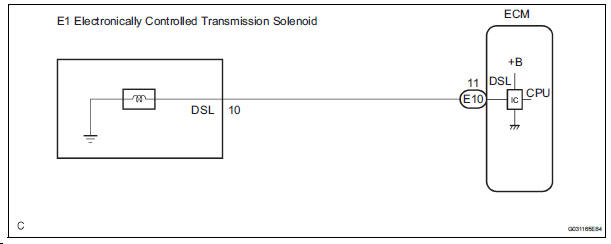

The shift solenoid valve DSL is turned "ON" and "OFF" by signals from the ECM

in order to control the

hydraulic pressure operation, the lock-up relay valve, which then controls

operation of the lock-up clutch.

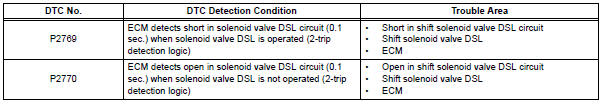

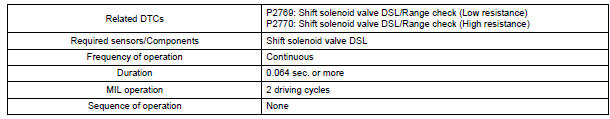

MONITOR DESCRIPTION

Torque converter lock-up is controlled by the ECM based on engine rpm, engine load, engine temperature, vehicle speed, transmission temperature, and shift range selection. The ECM determines the lock-up status of the torque converter by comparing the engine rpm (NE) to the input turbine rpm (NT).

The ECM calculates the actual transmission gear by comparing input turbine rpm (NT) to counter gear rpm (NC). When conditions are appropriate, the ECM requests "lock-up" by applying control voltage to the shift solenoid DSL. When the DSL is opened, it applies pressure to the lock-up relay valve and locks the torque converter clutch. If the ECM detects an open or short in the DSL solenoid circuit, the ECM interprets this as a fault in the DSL solenoid or circuit. The ECM will turn on the MIL and store the DTC.

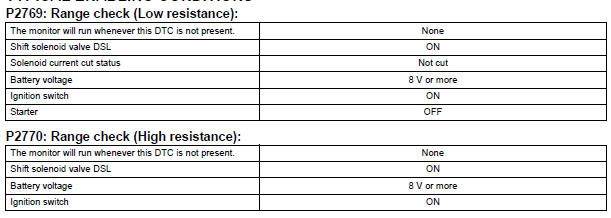

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

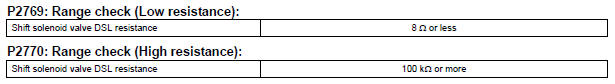

TYPICAL MALFUNCTION THRESHOLDS

COMPONENT OPERATING RANGE

WIRING DIAGRAM

INSPECTION PROCEDURE

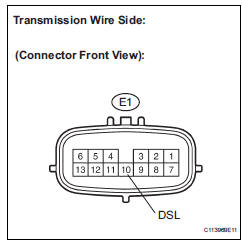

1 INSPECT TRANSMISSION WIRE (DSL)

(a) Disconnect the transmission wire connector from the transaxle.

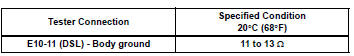

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

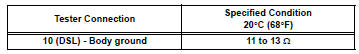

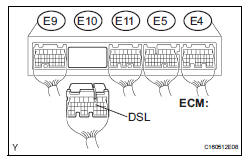

2 CHECK HARNESS AND CONNECTOR (TRANSMISSION WIRE - ECM)

(a) Connect the transmission wire connector.

(b) Disconnect the ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard resistance

REPLACE ECM

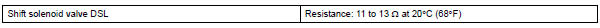

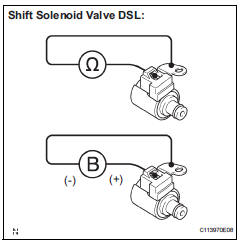

3 INSPECT SHIFT SOLENOID VALVE DSL

(a) Remove the shift solenoid valve DSL.

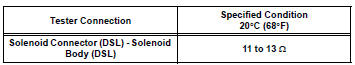

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

(c) Connect the positive (+) lead to the terminal of the solenoid connector, and the negative (-) lead to the solenoid body.

OK: The solenoid valve makes an operating sound.

REPAIR OR REPLACE TRANSMISSION WIRE

Pressure Control Solenoid "D" Electrical (Shift

Solenoid Valve SLT)

Pressure Control Solenoid "D" Electrical (Shift

Solenoid Valve SLT)

DESCRIPTION

The linear solenoid valve (SLT) controls the transmission line pressure for

smooth transmission operation

based on signals from the throttle position sensor and the vehicle speed senso ...

Other materials:

Precaution

NOTICE:

Perform the RESET MEMORY (AT initialization) when

replacing the automatic transaxle assembly, engine

assembly or ECM (See page AX-16).

Perform the REGISTRATION (VIN registration) when

replacing the ECM (See page ES-15).

HINT:

RESET MEMORY can not be ...

AUX Port/USB Port

Connect an iPod, USB memory device or portable audio player

to the AUX port/USB port as indicated below. Select “iPod”,

“USB” or “AUX” on the audio source selection screen and the

device can be operated via audio system.

Connecting using the AUX port/USB port

iPod

Open the cove ...

Summary of functions

Dynamic radar cruise control supplements conventional cruise control

with a vehicle-to-vehicle distance control. In vehicle-to-vehicle distance

control mode, the vehicle automatically accelerates or decelerates

in order to maintain a set following distance from vehicles ahead.

Multi-infor ...