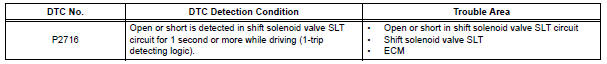

Toyota Sienna Service Manual: Pressure Control Solenoid "D" Electrical (Shift Solenoid Valve SLT)

DESCRIPTION

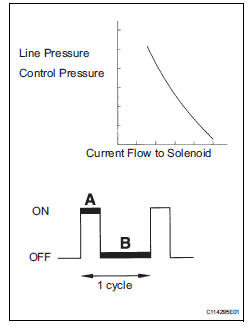

The linear solenoid valve (SLT) controls the transmission line pressure for smooth transmission operation based on signals from the throttle position sensor and the vehicle speed sensor. The ECM adjusts the duty cycle of the SLT solenoid valve to control hydraulic line pressure coming from the primary regulator valve. Appropriate line pressure assures smooth shifting with varying engine outputs.

(*): Duty Ratio The duty ratio is the ratio of the period of continuity in one cycle.

For example, if A is the period of continuity in one cycle, and B is the period

of non-continuity, then

Duty Ratio = A/(A + B) x 100(%)

MONITOR DESCRIPTION

When an open or short in the linear solenoid valve (SLT) circuit is detected, the ECM interprets this as a fault. The ECM will turn on the MIL and store the DTC.

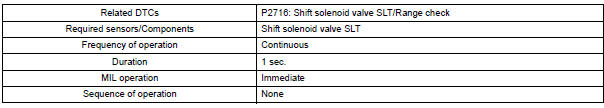

MONITOR STRATEGY

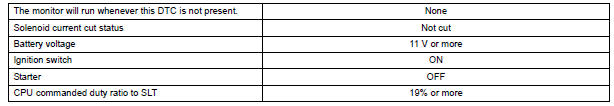

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

COMPONENT OPERATING RANGE

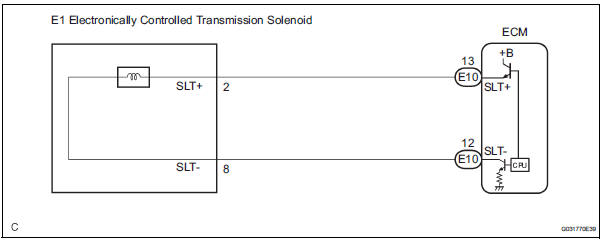

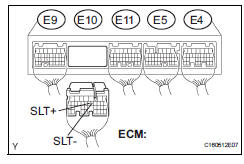

WIRING DIAGRAM

INSPECTION PROCEDURE

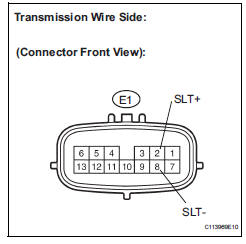

1 INSPECT TRANSMISSION WIRE (SLT)

(a) Disconnect the transmission wire connector from the transaxle.

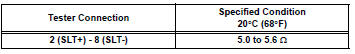

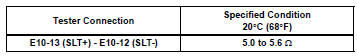

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

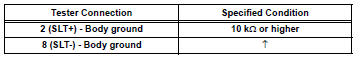

(c) Measure the resistance according to the value(s) in the table below.

Standard resistance (Check for short)

2 CHECK HARNESS AND CONNECTOR (TRANSMISSION WIRE - ECM)

(a) Connect the transmission wire connector to the transaxle.

(b) Disconnect the ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard resistance

(d) Measure the resistance according to the value(s) in the table below.

Standard resistance (Check for short)

REPLACE ECM

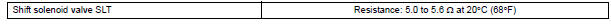

3 INSPECT SHIFT SOLENOID VALVE SLT

(a) Remove the shift solenoid valve (SLT).

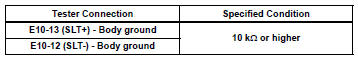

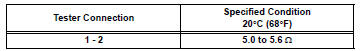

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

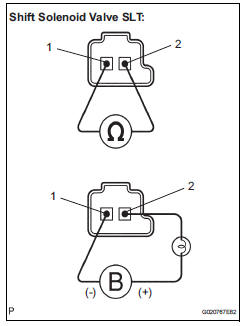

(c) Connect the positive (+) lead with a 21 W bulb to terminal 2 and the negative (-) lead to terminal 1 of the solenoid valve connector, then check the movement of the valve.

OK: The solenoid makes an operating sound.

REPAIR OR REPLACE TRANSMISSION WIRE

Pressure Control Solenoid "D" Performance (Shift

Solenoid Valve SLT)

Pressure Control Solenoid "D" Performance (Shift

Solenoid Valve SLT)

SYSTEM DESCRIPTION

The linear solenoid valve (SLT) controls the transmission line pressure for

smooth transmission operation

based on signals from the throttle position sensor and the vehicle spee ...

Torque Converter Clutch Solenoid Circuit

Torque Converter Clutch Solenoid Circuit

DESCRIPTION

The shift solenoid valve DSL is turned "ON" and "OFF" by signals from the ECM

in order to control the

hydraulic pressure operation, the lock-up relay valve, whi ...

Other materials:

Basic inspection

When a malfunction is not confirmed by the DTC check,

troubleshooting should be carried out in all circuits

considered to be possible causes of the problem. In many

cases, by carrying out the basic engine check shown in the

following flowchart, the location of the problem can be found

quickly a ...

Hood

COMPONENTS

Adjustment

HINT:

Since a centering bolt is used as a hood hinge mounting bolt

and hood lock mounting bolt, the hood and hood lock can not

be adjusted with them on. Substitute a bolt with a washer for

the centering bolt.

1. INSPECT HOOD SUB-ASSEMBLY

Check that the clearance is ...

A/F Sensor Circuit Slow Response

DTC P2A00 A/F Sensor Circuit Slow Response (Bank 1

Sensor 1)

DTC P2A03 A/F Sensor Circuit Slow Response (Bank 2

Sensor 1)

HINT:

DTC P2A00 indicates malfunctions related to the bank 1 A/F sensor.

DTC P2A03 indicates malfunctions related to the bank 2 A/F sensor.

Bank 1 r ...