Toyota Sienna Service Manual: Trouble in Passenger Airbag ON / OFF Indicator

DESCRIPTION

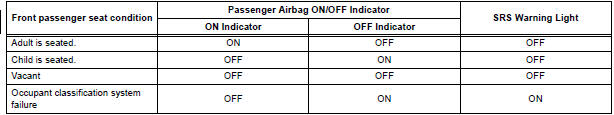

The occupant classification system detects the front passenger seat condition. It then informs a passenger of the front passenger airbag, the front seat side airbag RH and front seat belt pretensioner RH condition (activated/not activated) by the passenger airbag ON/OFF indicator.

HINT: Approximately 6 seconds after the ignition switch is turned to the ON position, the passenger airbag ON/ OFF indicator will be ON/OFF depending on the conditions listed below.

INSPECTION PROCEDURE

1 CHECK SRS WARNING LIGHT

- Turn the ignition switch to the ON position, and check the SRS warning light condition.

HINT: If this trouble occurs, the SRS warning light is off. If it is on, a DTC is output. Troubleshoot for the output DTC.

OK: After the primary check period, SRS warning light goes off.

HINT: The primary check period is approximately 6 seconds after the ignition switch is turned to the ON position.

2 PERFORM ZERO POINT CALIBRATION

- Turn the ignition switch to the LOCK position.

- Connect the intelligent tester to the DLC3.

- Turn the ignition switch to the ON position.

- Using the intelligent tester, perform "Zero point calibration".

OK: "COMPLETE" is displayed.

3 PERFORM SENSITIVITY CHECK

- Using the intelligent tester, perform "Sensitivity check".

Standard value: 27 to 33 kg (59.52 to 72.75 lb)

END

4 RETIGHTEN FRONT SEAT ASSEMBLY RH BOLT

- Turn the ignition switch to the LOCK position.

- Loosen the 4 installation bolts of the front seat assembly RH.

- Tighten the 4 installation bolts of the front seat assembly RH to the specified torque.

Torque: 37 N*m (375 kgf*cm, 27 ft.*lbf)

5 PERFORM ZERO POINT CALIBRATION

- Connect the intelligent tester to the DLC3.

- Turn the ignition switch to the ON position.

- Using the intelligent tester, perform "Zero point calibration".

OK: "COMPLETE" is displayed.

6 PERFORM SENSITIVITY CHECK

- Using the intelligent tester, perform "Sensitivity check".

Standard value: 27 to 33 kg (59.52 to 72.75 lb)

END

7 CHECK CONNECTORS

- Turn the ignition switch to the LOCK position.

- Disconnect the negative (-) terminal cable from the battery, and wait for at least 90 seconds.

- Check the connectors are properly connected to the

occupant classification ECU and the 4 occupant

classification sensors.

OK: The connectors are connected.

- Disconnect the connectors from the occupant classification ECU and the 4 occupant classification sensors.

- Check the connectors are not damaged or deformed.

OK: The connectors are properly normal.

8 CHECK DTC

- Connect the connectors to the occupant classification ECU and the 4 occupant classification sensors.

- Connect the negative (-) terminal cable to the battery.

- Turn the ignition switch to the ON position, and wait for at least 60 seconds.

- Turn the ignition switch to the LOCK position.

- Clear the DTCs stored in the memory.

- Turn the ignition switch to the ON position, and wait for at least 60 seconds.

- Check the DTCs.

OK: DTC is not output.

9 REPLACE OCCUPANT CLASSIFICATION ECU

- Turn the ignition switch to the LOCK position.

- Disconnect the negative (-) terminal cable from the battery, and wait for at least 90 seconds

- Replace the occupant classification ECU

10 PERFORM ZERO POINT CALIBRATION

- Connect the negative (-) terminal cable to the battery.

- Connect the intelligent tester to the DLC3.

- Turn the ignition switch to the ON position.

- Using the intelligent tester, perform "Zero point calibration".

OK: "COMPLETE" is displayed.

11 PERFORM SENSITIVITY CHECK

- Using the intelligent tester, perform "Sensitivity check".

Standard value: 27 to 33 kg (59.52 to 72.75 lb)

END

Sleep Operation Failure of Occupant Classification

ECU

Sleep Operation Failure of Occupant Classification

ECU

DTC B1796 Sleep Operation Failure of Occupant Classification

ECU

DESCRIPTION

During sleep mode, the occupant classification ECU reads the condition of

each sensor while the ignition

switch is of ...

Steering pad

Steering pad

Components

...

Other materials:

Disc cannot be Played/ No Playable Files/ Copyright Protection Error/ Disc

cannot be Played/ No Playable Files/ Copyright Protection Error

DTC 62-7D Disc cannot be Played

DTC 62-7E No Playable Files

DTC 62-7F Copyright Protection Error

DTC 63-7D Disc cannot be Played

DTC 63-7E No Playable Files

DTC 63-7F Copyright Protection Error

DESCRIPTION

INSPECTION PROCEDURE

HINT:

After the inspection is completed, clear the DTCs.

1 ...

Radio antenna pole

COMPONENTS

REMOVAL

1. REMOVE PULL TOP ANTENNA POLE SUBASSEMBLY

Remove the pull top antenna pole sub-assembly by

pulling it the arrow direction in the illustration.

INSTALLATION

1. INSTALL PULL TOP ANTENNA POLE SUBASSEMBLY ...

Data list / active test

HINT:

By accessing the DATA LIST displayed on the intelligent

tester, you can perform such functions as reading the values

of switches and sensors without removing any parts. Reading

the DATA LIST as the first step in troubleshooting is one

method to shorten labor time.

1. DATA LIST FOR CENTER ...