Toyota Sienna Service Manual: Adjustment

HINT: On the RH side, use the same procedures as on the LH side.

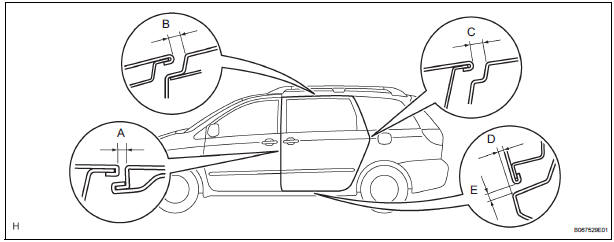

1. INSPECT SLIDE DOOR PANEL SUB-ASSEMBLY LH

- Check that the clearance is within the standard range.

Standard

2. ADJUST SLIDE DOOR PANEL SUB-ASSEMBLY LH

- Using the SST, horizontally and vertically adjust the

door by loosening the hinge center bolts.

SST 09812-00010, 09812-00020

- Tighten the hinge assembly center bolts after the

adjustment.

Torque: 31 N*m (306 kgf*cm, 23 ft.*lbf)

- Vertically adjust the front side of the door by loosening the roller lower bolts.

- Tighten the roller lower bolts after the adjustment.

Torque: 31 N*m (306 kgf*cm, 23 ft.*lbf)

- Horizontally adjust the front lower side of the door by loosening the roller lower bolts.

- Tighten the roller lower bolts after the adjustment.

Torque: 31 N*m (306 kgf*cm, 23 ft.*lbf)

- Horizontally adjust the front upper side of the door by loosening the roller upper bolts.

- Tighten the roller assembly lower bolts after the

adjustment.

Torque: 8.5 N*m (82 kgf*cm, 73 in.*lbf)

- Adjust the position of the door lock striker by slightly loosening the striker mounting screws and hitting the striker with a plastic-faced hammer.

- Tighten the striker mounting screws after the

adjustment.

Torque: 23 N*m (235 kgf*cm, 17 ft.*lbf)

- Adjust the position of the front lock striker by slightly loosening the striker mounting screws and hitting the striker with a plastic-faced hammer.

- Tighten the striker mounting screws after the

adjustment.

Torque: 23 N*m (235 kgf*cm, 17 ft.*lbf)

- Adjust the position of the down stopper by moving the male stopper, so that the male stopper can enter smoothly.

- Tighten the female stopper mounting bolts after the

adjustment.

Torque: 5.5 N*m (58 kgf*cm, 49 in.*lbf)

Disassembly

Disassembly

HINT:

On the RH side, use the same procedures as on the LH side.

1. REMOVE REAR DOOR WINDOW FRAME MOULDING

REAR LH (See page ET-30)

2. REMOVE REAR DOOR WINDOW FRAME MOULDING

SUB-ASSEMBLY LH (See ...

Reassembly

Reassembly

1. INSTALL REAR DOOR WIRE SUB-ASSEMBLY LH

Install the wire.

NOTICE:

When installing the wire, push the areas where

the clips are installed in order to prevent

damage and deformation.

...

Other materials:

Power Slide Door Pulse Sensor Malfunction on

Rear Right Door

DTC B2223 Power Slide Door Pulse Sensor Malfunction on

Rear Right Door

DESCRIPTION

A pulse sensor is built into slide door RH for jam and foreign

object detection and for slide door position

detection. The jam and foreign object detection feature of the pulse sensor

monitors the ...

Short to GND in Curtain Shield Squib LH Circuit

DTC B1167/85 Short to GND in Curtain Shield Squib LH Circuit

DESCRIPTION

The curtain shield squib LH circuit consists of the center airbag sensor

assembly and the curtain shield

airbag assembly LH.

The circuit instructs the SRS to deploy when deployment conditions are met.

DTC B1167/85 is ...

Inspection

1. INSPECT POWER STEERING RACK

(a) Using a dial indicator, check the power steering rack

for runout and for teeth wear and damage.

Maximum runout:

0.3 mm (0.012 in.)

If necessary, replace the rack & pinion power

steering gear assembly.

(b) Check the back surface for wear and damag ...