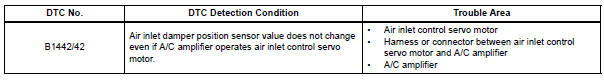

Toyota Sienna Service Manual: Air Inlet Damper Control Servo Motor Circuit

DESCRIPTION

The air inlet control servo motor is controlled by the A/C amplifier and moved to the desired position.

The air inlet control servo motor switches the air inlet mode by rotating

(normal, reverse) with electrical

power from the A/C amplifier. This controls intake air and changes the mode

between

"RECIRCULATION", "FRESH", and "HALF-RECIRCULATION".

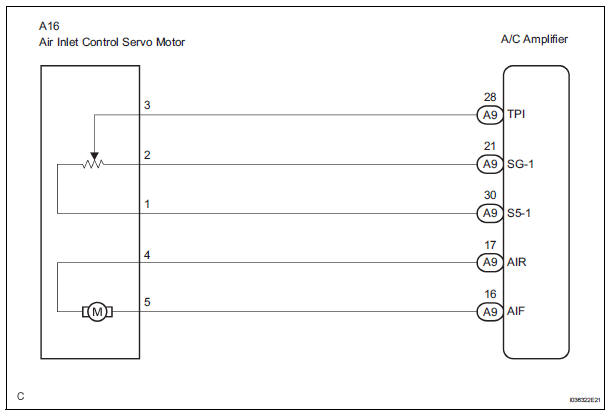

WIRING DIAGRAM

INSPECTION PROCEDURE

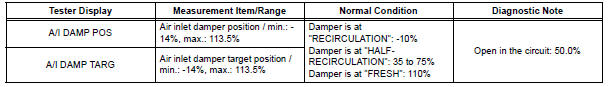

1 READ VALUE OF INTELLIGENT TESTER

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the intelligent tester main switch on.

(c) Select the items below in the DATA LIST, and read the display on the intelligent tester.

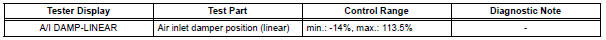

DATA LIST / AIR CONDITIONER

OK: When the target position is "RECIRCULATION" (- 10%), the actual opening angle is 19.0% or less.

When the target position is "FRESH" (110%), the actual opening angle is 81.0% or more.

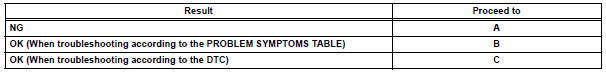

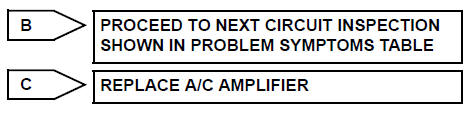

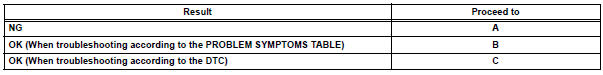

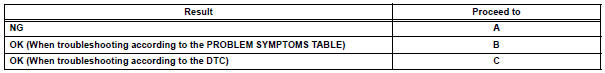

Result

2 PERFORM ACTIVE TEST BY INTELLIGENT TESTER

(a) Remove the glove box to see and check the recirculation damper operation.

(b) Connect the intelligent tester to the DLC3.

(c) Turn the ignition switch to the ON position and turn the intelligent tester main switch on.

(d) Select the item below in the ACTIVE TEST and then check that the damper operates.

ACTIVE TEST / AIR CONDITIONER

OK: Lever turns from "RECIRCULATION" side to "FRESH" side smoothly.

Lever turns from "FRESH" side to "RECIRCULATION" side smoothly.

Result

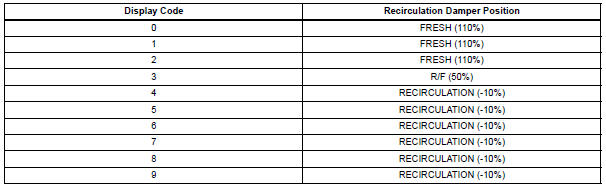

3 PERFORM ACTUATOR CHECK

(a) Remove the glove box to see and check the recirculation damper operation.

(b) Enter the actuator check mode (See page AC-15).

(c) Press the DEF switch and check the operation of the

recirculation damper.

OK: Recirculation damper position changes in accordance with each display code.

Result

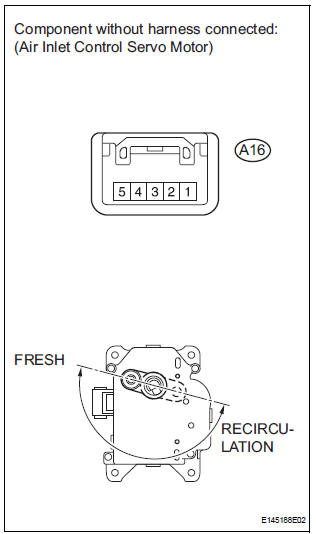

4 INSPECT AIR INLET CONTROL SERVO MOTOR

(a) Remove the air inlet control servo motor.

(b) Disconnect the connector from the air inlet control servo motor.

(c) Connect the positive (+) lead from the battery to terminal 5 and the negative (-) lead to terminal 4, then check that the lever turns to the "FRESH" position smoothly.

OK: Lever turns to "FRESH" position smoothly.

(d) Connect the positive (+) lead from the battery to terminal 4 and the negative (-) lead to terminal 5, then check that the lever turns to the "RECIRCULATION" position smoothly.

OK: Lever turns to "RECIRCULATION" position smoothly.

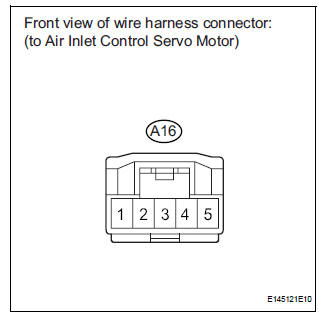

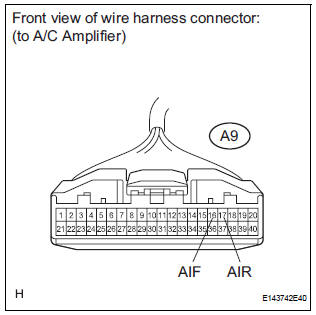

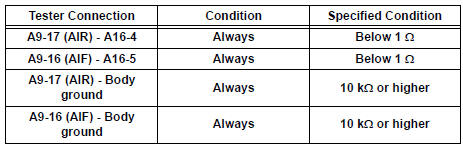

5 CHECK HARNESS AND CONNECTOR (AIR INLET CONTROL SERVO MOTOR - A/C AMPLIFIER)

(a) Disconnect the connector from the A/C amplifier.

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

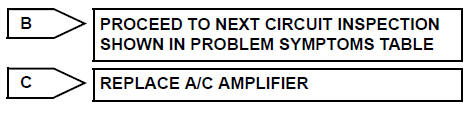

REPLACE A/C AMPLIFIER

Air Mix Damper Control Servo Motor Circuit (Passenger Side)

Air Mix Damper Control Servo Motor Circuit (Passenger Side)

DESCRIPTION

The air mix control servo motor (air mix damper servo sub-assembly) is

controlled by the A/C amplifier.

The air mix control servo motor moves the air mix damper by rotating (normal, ...

Air Outlet Damper Control Servo Motor Circuit

Air Outlet Damper Control Servo Motor Circuit

DESCRIPTION

This circuit turns the servo motor and changes each damper position by

receiving the signals from the A/

C amplifier.

The air outlet damper servo motor switches the air outlet mode ...

Other materials:

Back Door Closer does not Operate

DESCRIPTION

The power back door ECU controls the back door closer system. In response to

the signals output from

the switches related to the back door lock, the back door latch activates the

closer motor.

HINT:

The back door closer system operates regardless of whether the power back door

...

Disassembly

1. INSPECT UNDERDRIVE PLANETARY GEAR

PRELOAD

HINT:

(See page AX-260)

2. REMOVE FRONT PLANETARY GEAR NUT

(a) Using SST, loosen the staked part of the lock nut.

SST 09930-00010 (09931-00010, 09931-00020),

09387-00050

(b) Place the underdrive planetary gear in a soft jaw

vise.

NOTIC ...

Cursor or Map Rotates when Vehicle Stopped

INSPECTION PROCEDURE

1 CHECK CONDITION

Check with the customer if the vehicle has been turned

by a turntable.

OK:

Vehicle has not been turned by turntable.

HINT:

If the vehicle is turned on a turntable with the ignition

switch on, the system may store the angular velocity. As

a ...