Toyota Sienna Service Manual: Basic inspection

When a malfunction is not confirmed by the DTC check, troubleshooting should be carried out in all circuits considered to be possible causes of the problem. In many cases, by carrying out the basic engine check shown in the following flowchart, the location of the problem can be found quickly and efficiently. Therefore, using this check is essential when engine troubleshooting.

1 CHECK BATTERY VOLTAGE

| NOTICE: Carry out this check with the engine stopped and ignition switch off. |

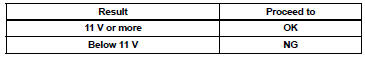

Result

2 CHECK WHETHER ENGINE CRANKS

3 CHECK WHETHER ENGINE STARTS

4 CHECK AIR FILTER

(a) Visually check that the air filter is not excessively contaminated with dirt or oil.

5 CHECK IDLING SPEED

(a) Check the idling speed (See page EM-2).

6 CHECK FUEL PRESSURE

(a) Check the fuel pressure (See page FU-7).

7 CHECK FOR SPARKS

(a) Check for sparks (See page ES-217).

PROCEED TO PROBLEM SYMPTOMS TABLE

Check for intermittent problems

Check for intermittent problems

1. CHECK FOR INTERMITTENT PROBLEMS

HINT:

For use of the intelligent tester only:

Inspect the vehicle's ECM using check mode.

Intermittent problems are easier to detect with an

intelligent teste ...

Registration

Registration

NOTICE:The Vehicle Identification Number (VIN) must be

input

into the replacement ECM.

HINT:

The VIN is a 17-digit alphanumeric vehicle identification

number. The intelligent tes ...

Other materials:

Precaution

1. Before operating the power rear no. 2 seat with

stowing function, make sure that there is nothing in

the path of the seat.

CAUTION:

If someone or something is caught between the seat

and other parts, injury or damage may result.

If the system detects that the folding motor is locke ...

Installing child restraints

Follow the child restraint system manufacturer’s instructions.

Firmly secure child restraints to the rear seats using the LATCH

anchors or a seat belt. Attach the top tether strap when installing

a child restraint.

The lap/shoulder belt can be used if your child restraint sy ...

Terminals of ECU

1. CENTER AIRBAG SENSOR ASSEMBLY (w/ Side

Airbag)

2. CENTER AIRBAG SENSOR ASSEMBLY (w/o Side

Airbag)

...