Toyota Sienna Service Manual: Camshaft Position Sensor

DTC P0365 Camshaft Position Sensor "B" Circuit (Bank 1)

DTC P0367 Camshaft Position Sensor "B" Circuit Low Input (Bank 1)

DTC P0368 Camshaft Position Sensor "B" Circuit High Input (Bank 1)

DTC P0390 Camshaft Position Sensor "B" Circuit (Bank 2)

DTC P0392 Camshaft Position Sensor "B" Circuit Low Input (Bank 2)

DTC P0393 Camshaft Position Sensor "B" Circuit High Input (Bank 2)

DESCRIPTION

The exhaust camshaft's Variable Valve Timing (VVT) sensor consists of a magnet and MRE (Magneto Resistance Element).

The exhaust camshaft has a sensor plate with 3 teeth on its outer circumference.

When the exhaust camshaft rotates, changes occur in the air gaps between the 3 teeth and MRE, which affects the magnet. As a result, the resistance of the MRE material fluctuates. The VVT sensor converts the exhaust camshaft rotation data to pulse signals, uses the pulse signals to determine the camshaft angle, and sends it to the ECM.

|

DTC No. |

DTC Detection Condition |

Trouble Area |

| P0365 P0390 |

|

|

| P0367 P0392 |

Output voltage of VVT sensor is 0.3 V or less for 5 seconds (1 trip detection logic) |

|

| P0368 P0393 |

Output voltage of VVT sensor is 4.7 V or more for 5 seconds (1 trip detection logic) |

|

MONITOR DESCRIPTION

If no signal is transmitted by the VVT (for exhaust camshaft) sensor despite the engine revolving, or the rotations of the exhaust camshaft and the crankshaft are not synchronized, the ECM interprets this as a malfunction of the sensor

MONITOR STRATEGY

| Related DTCs | P0365: Exhaust camshaft sensor (Bank 1) range check / rationality

(while starting

engine) P0365: Exhaust camshaft sensor (Bank 1) range check / rationality (after starting engine) P0365: Exhaust camshaft sensor (Bank 1) range check (chattering) P0367: Exhaust camshaft sensor (Bank 1) range check (low voltage) P0368: Exhaust camshaft sensor (Bank 1) range check (high voltage) P0390: Exhaust camshaft sensor (Bank 2) range check / rationality (while starting engine) P0390: Exhaust camshaft sensor (Bank 2) range check / rationality (after starting engine) P0390: Exhaust camshaft sensor (Bank 2) range check (chattering) P0392: Exhaust camshaft sensor (Bank 2) range check (low voltage) P0393: Exhaust camshaft sensor (Bank 2) range check (high voltage) |

| Required Sensors / Components (Main) | Exhaust camshaft sensor (Bank 1 and 2) |

| Required Sensors / Components (Related) | Exhaust camshaft sensor |

| Frequency of Operation | Continuous |

| Duration | 5 seconds: Exhaust camshaft sensor range check / rationality (After starting engine) 4 seconds: Others |

| MIL Operation | 2 driving cycles: Exhaust camshaft sensor range check / rationality (After starting engine) Immediate: Others |

| Sequence of Operation | None |

TYPICAL ENABLING CONDITIONS

All:

| The monitor will run whenever these DTCs are not present | None |

Exhaust Camshaft Sensor Range Check / Rationality (While starting engine):

| Starter | ON |

| Battery voltage while starter is ON at least once | Less than 11 V |

Exhaust Camshaft Sensor Range Check / Rationality (After starting engine):

| Engine RPM | 600 rpm or more |

| Starter | OFF |

| Battery voltage | 8 V or more |

| Ignition Switch | ON |

Exhaust Camshaft Sensor Range Check (Chattering, Low voltage, High voltage):

| Starter | OFF |

| Ignition Switch ON and time after ignition switch is OFF to ON | 2 seconds or more |

| Battery voltage | 8 V or more |

TYPICAL MALFUNCTION THRESHOLDS

Exhaust Camshaft Sensor Range Check / Rationality (While starting engine):

| Exhaust camshaft sensor signal | No signal |

Exhaust Camshaft Sensor Range Check / Rationality (After starting engine):

| Exhaust camshaft sensor signal | No signal |

Exhaust Camshaft Sensor Range Check (Chattering):

| Exhaust camshaft sensor signal | Less than 0.3 V, or more than 4.7 V |

Exhaust Camshaft Sensor Range Check (Low voltage):

| Exhaust camshaft sensor signal | Less than 0.3 V |

Exhaust Camshaft Sensor Range Check (High voltage):

| Exhaust camshaft sensor signal | More than 4.7 V |

WIRING DIAGRAM

Refer to DTC P0335

INSPECTION PROCEDURE

HINT: Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data can be helpful in determining whether the vehicle was running or stopped, whether the engine was warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the time of a malfunction.

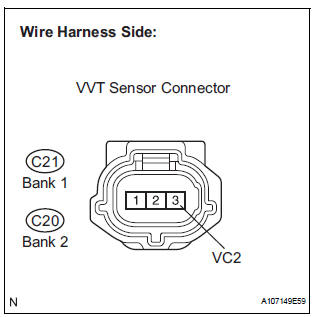

1 CHECK VVT SENSOR FOR EXHAUST CAMSHAFT (SENSOR POWER SOURCE)

- Disconnect the C21 or C20 VVT sensor connector.

- Measure the voltage according to the value(s) in the table below.

Standard voltage

OK

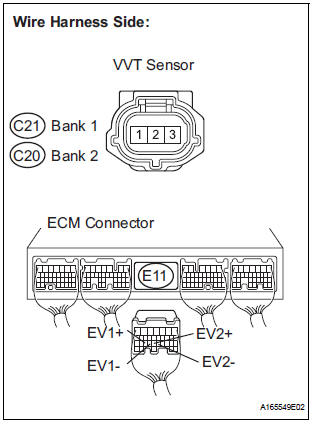

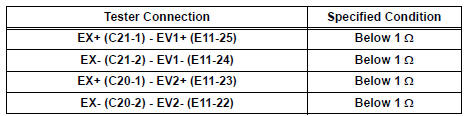

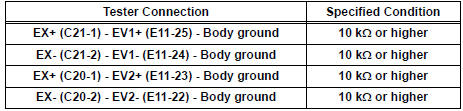

2 CHECK HARNESS AND CONNECTOR (VVT SENSOR - ECM)

- Disconnect the C21 or C20 VVT sensor for exhaust camshaft connector.

- Disconnect the E11 ECM connector.

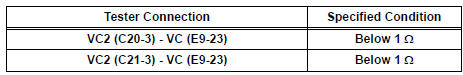

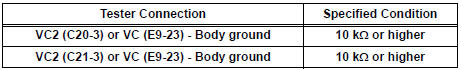

- Measure the resistance between the wire harness side connectors.

Standard resistance: Check for open

Check for short

OK

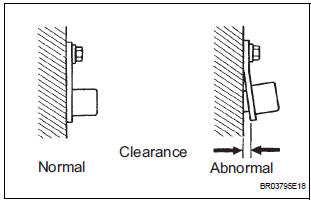

3 CHECK VVT SENSOR FOR EXHAUST CAMSHAFT (SENSOR INSTALLATION)

- Check the VVT sensor installation.

OK: Sensor is installed correctly.

NG

OK REPAIR OR REPLACE VVT SENSOR

4 CHECK EXHAUST CAMSHAFT

- Check the teeth of the camshaft

NG REPLACE EXHAUST CAMSHAFT

OK

5 REPLACE VVT SENSOR (FOR EXHAUST CAMSHAFT)

- Replace the VVT sensor

NEXT

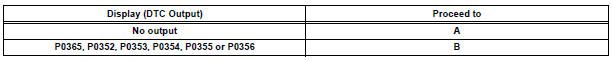

6 CHECK WHETHER DTC OUTPUT RECURS

- Connect the intelligent tester to the DLC3.

- Turn the ignition switch to the ON position.

- Turn the intelligent tester on.

- Clear the DTCs.

- Select the following menu items: DIAGNOSIS / ENHANCED OBD II / DTC / INFO / PENDING CODES.

- Read the DTCs

Result

HINT: If the engine does not start, replace the ECM.

B REPLACE ECM

A

END

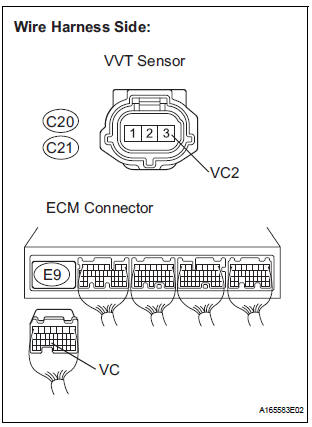

7 CHECK HARNESS AND CONNECTOR (VVT SENSOR - ECM)

- Disconnect the C18 or C19 VVT sensor connector.

- Disconnect the E9 ECM connector.

- Measure the resistance according to the value(s) in the table below.

Standard resistance : Check for open

Check for short

- Reconnect the VVT sensor connector.

- Reconnect the ECM connector

NG REPAIR OR REPLACE HARNESS OR CONNECTOR (VVT SENSOR - ECM)

OK

REPLACE ECM

Ignition Coil Primary / Secondary Circuit

Ignition Coil Primary / Secondary Circuit

DTC P0351 Ignition Coil "A" Primary / Secondary Circuit

DTC P0352 Ignition Coil "B" Primary / Secondary Circuit

DTC P0353 Ignition Coil "C" Primary / Secondary Circuit

...

Catalyst System Efficiency Below Threshold

Catalyst System Efficiency Below Threshold

DTC P0420 Catalyst System Efficiency Below Threshold

(Bank 1)

DTC P0430 Catalyst System Efficiency Below Threshold

(Bank 2)

MONITOR DESCRIPTION

The ECM uses the sensors mounted in front of and be ...

Other materials:

Short to B+ in Side Squib RH Circuit

DTC B0113/42 Short to B+ in Side Squib RH Circuit

DESCRIPTION

The side squib RH circuit consists of the center airbag sensor assembly and

the front seat side airbag

assembly RH.

This circuit instructs the SRS to deploy when deployment conditions are met.

DTC B0113/42 is recorded when a sh ...

Open in Front Passenger Side Squib Circuit

DTC B0106/54 Open in Front Passenger Side Squib Circuit

DESCRIPTION

The front passenger side squib circuit consists of the center airbag sensor

assembly and the front

passenger airbag assembly.

The circuit instructs the SRS to deploy when deployment conditions are met.

DTC B0106/54 is rec ...

Jam Protection Function Activates During Power Back Door Operation

DESCRIPTION

It may be caused by ill-fitting back door, faulty touch sensor or

faulty pulse sensor.

The power back door ECU activates the back motor to open / close

the power back door, thus

controlling the power back door operation. For jam and foreign object

detection, the power ba ...