Toyota Sienna Service Manual: Disassembly

1. REMOVE FUEL TANK TO FILLER PIPE HOSE (See page FU-43)

2. REMOVE FUEL TANK MAIN TUBE SUB-ASSEMBLY

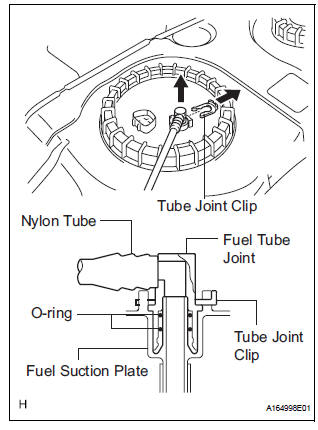

(a) Remove the tube joint clip, and pull out the fuel main tube.

NOTICE:

|

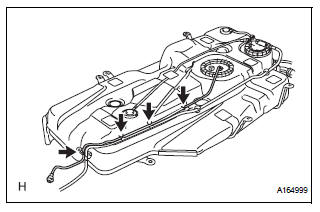

(b) Unfasten the 4 claws and remove the fuel tank main tube from the fuel tank.

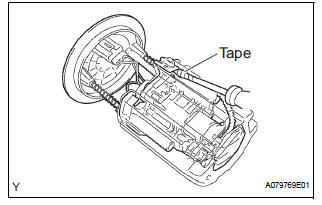

3. REMOVE FUEL SUCTION TUBE ASSEMBLY WITH PUMP AND GAUGE

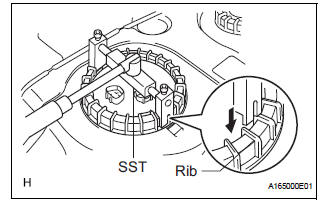

(a) Using SST, loosen the fuel pump gauge retainer.

SST 09808-14020 (09808-01410, 09808-01420, 09808-01430)

HINT: A rib on the fuel pump gauge retainer can be fitted into a tip of SST.

(b) Remove the fuel pump gauge retainer.

(c) Remove the fuel suction tube assembly with pump and gauge and the fuel suction tube set gasket from the fuel tank.

| NOTICE: Be careful not bend the arm of the fuel sender gauge. |

4. REMOVE FUEL SENDER GAUGE ASSEMBLY

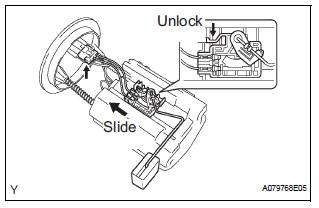

(a) Disconnect the fuel sender gauge connector.

(b) Unlock the fuel sender gauge and slide it to remove.

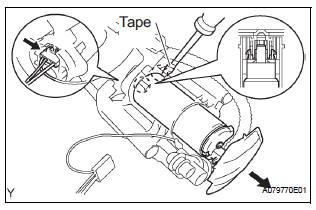

5. REMOVE FUEL SUCTION PLATE SUB-ASSEMBLY

(a) Using a screwdriver with the tip wrapped in tape, disconnect the 4 snap-claws from the claw holes and remove the fuel suction plate.

| NOTICE: Do not damage the fuel suction plate and the No. 1 fuel suction support. |

6. REMOVE FUEL PUMP

(a) Disconnect the fuel pump connector.

(b) Using a small screwdriver with the tip wrapped in tape, disconnect the 2 claws from the claw holes and pull out the fuel pump.

| NOTICE: Do not damage the fuel pump and the fuel suction plate. |

(c) Remove the O-ring and the fuel pump spacer from the fuel pump.

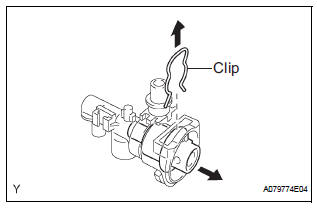

7. REMOVE FUEL FILTER ASSEMBLY

(a) Using a small screwdriver, pry out the clip.

(b) Remove the fuel filter assembly from the fuel pump.

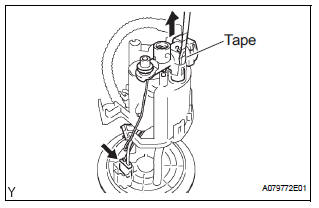

8. REMOVE NO. 1 FUEL TUBE JOINT

(a) Remove the connector.

(b) Using a screwdriver with the tip wrapped in tape, disconnect the snap-claw from the claw hole and pull out the No. 1 fuel tube joint.

| NOTICE: Do not damage the No. 1 fuel tube joint and the fuel suction plate. |

9. REMOVE FUEL PUMP HARNESS

(a) Remove the fuel pump harness from the No. 1 fuel tube joint.

10. REMOVE FUEL PRESSURE REGULATOR ASSEMBLY

(a) Remove the clip.

(b) Pull out the fuel pressure regulator from the fuel suction plate.

(c) Remove the 2 O-rings from the fuel pressure regulator.

Removal

Removal

1. DISCHARGE FUEL SYSTEM PRESSURE

(See page FU-1)

2. REMOVE CHARCOAL CANISTER PROTECTOR

(a) Remove the 6bolts and the charcoal canister

protector.

3. REMOVE REAR FLOOR NO. 2 CROSSMEMBER

BRACE LH ...

Inspection

Inspection

1. INSPECT FUEL PUMP

(a) Inspect fuel pump resistance.

(1) Using an ohmmeter, measure the resistance

between the terminals.

Standard resistance

(b) Inspect fuel pump operation

(1) Apply ...

Other materials:

Electronic control

(a) REMOVAL AND INSTALLATION OF BATTERY TERMINAL

REMOVAL AND INSTALLATION OF BATTERY TERMINAL

NOTICE: Certain systems need to be initialized

after

disconnecting and reconnecting the cable from

the negative (-) battery terminal.

(1) Before performing electronic work, disconnect

the ...

Disassembly

1. REMOVE 2ND BRAKE PISTON RETURN SPRING

SUB-ASSEMBLY

(a) Place SST on the return spring and compress the

return spring with a press.

SST 09387-00060

(b) Using a screwdriver, remove the snap ring.

(c) Remove the 2nd brake piston return spring.

2. REMOVE 2ND BRAKE PISTON

(a) Hold ...

Headlight leveling switch

ON-VEHICLE INSPECTION

1. HEADLIGHT LEVELING SWITCH

Connect the battery positive (+) lead to the terminal

1 and the battery negative (-) lead to the terminal 5.

Measure the resistance between the terminal 4 and

the battery negative (-) lead when headlight leveling

switch ...