Toyota Sienna Service Manual: Disassembly

1. INSPECT UNDERDRIVE PACK CLEARANCE

HINT: (See page AX-262)

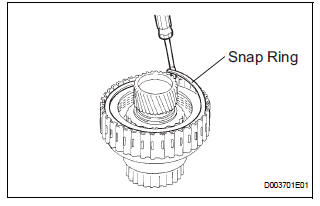

2. REMOVE UNDERDRIVE CLUTCH FLANGE NO.2 HOLE SNAP RING

a) Using a screwdriver, remove the underdrive clutch flange No.2 snap ring.

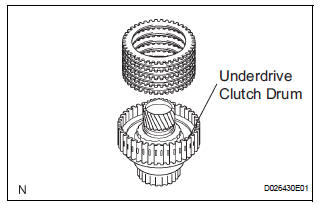

3. REMOVE UNDERDRIVE CLUTCH DISC NO.1

(a) Remove the flange, 4 discs and 4 plates from the underdrive clutch drum.

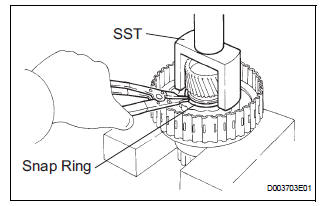

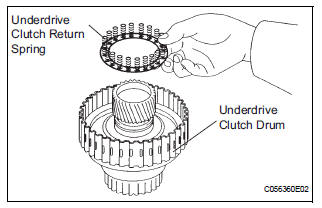

4. REMOVE UNDERDRIVE CLUTCH RETURN SPRING SUB-ASSEMBLY

(a) Place SST on the clutch balancer and compress the spring with a press.

SST 09350-32014

(b) Using a snap ring expander, remove the snap ring.

NOTICE:

- Stop the press when the spring seat is lowered to the place 1 to 2 mm (0.039 to 0.078 in.) from the snap ring groove.

- This prevents the spring seat from being deformed.

- Do not expand the snap ring excessively.

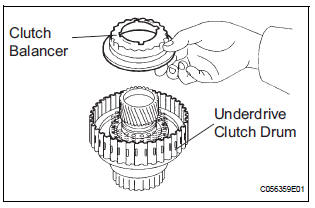

(c) Remove the clutch balancer from the underdrive clutch drum.

(d) Remove the return spring from the underdrive clutch drum.

5. REMOVE UNDERDRIVE CLUTCH PISTON SET

(a) Install the underdrive clutch to the transaxle case.

NOTICE: Be careful not to damage the oil seal ring.

(b) Holding the underdrive clutch piston by hand, apply compressed air (392 kPa, 4.0 kgf/cm2, 57 psi) to the transaxle case to remove the underdrive clutch piston.

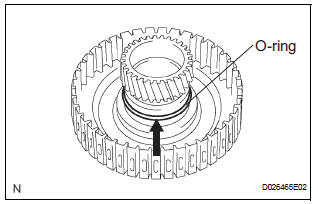

6. REMOVE UNDERDRIVE CLUTCH DRUM O-RING

(a) Using a screwdriver, remove the O-ring from the underdrive clutch drum.

Underdrive clutch

Underdrive clutch

COMPONENTS

...

Inspection

Inspection

1. INSPECT UNDERDRIVE PACK CLEARANCE

(a) Install the underdrive clutch to the transaxle case.

NOTICE:

Be careful not to damage the oil seal rings.

(b) Install a dial indicator as shown in the ...

Other materials:

For rear air conditioning system

ON-VEHICLE INSPECTION

1. INSPECT REAR AIR MIX CONTROL SERVO MOTOR

(a) Inspect servo motor operation.

(1) Connect the positive (+) lead from the battery

to terminal 4 and negative (-) lead to terminal 5,

then check that the arm turns to "HOT" side

smoothly.

(2) Connect the po ...

Adjustment

CAUTION:

Do not stare at the luminous portion of the laser

during adjustment. The intensity of the laser light is

low, but it may result in loss of sight.

If operation is not carried out as specified, there may

be a risk that you are exposed to hazardous radiation.

HINT:

...

Removal

1. Remove rear wheel

2. Remove skid control sensor wire (for 2wd)

Hint:

(see page sp-38)

hint:

disconnect the rh side by the same procedures as the

lh side.

3. SEPARATE SPEED SENSOR REAR LH (for 4WD)

HINT:

(See page SP-38)

4. SEPARATE SPEED SENSOR REAR RH (for 4WD)

HINT:

Separate the RH ...