Toyota Sienna Service Manual: Engine coolant temperature sensor

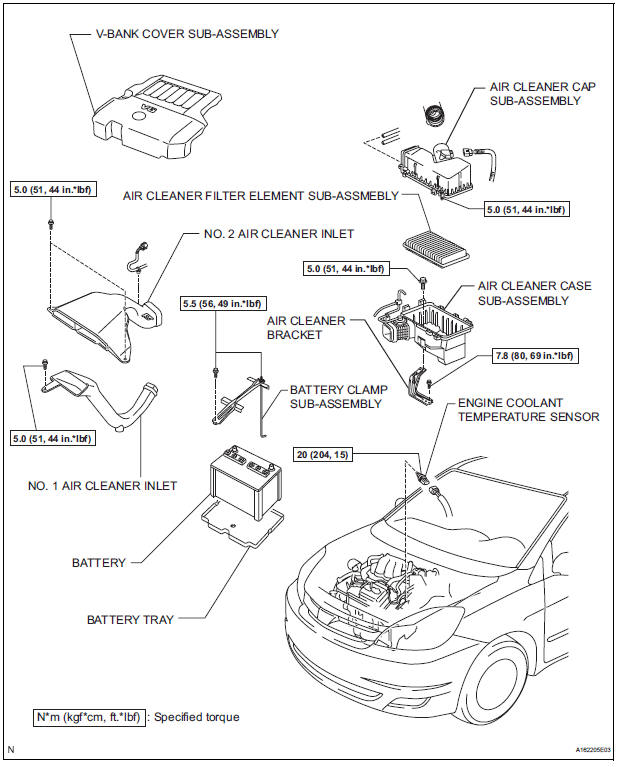

COMPONENTS

REMOVAL

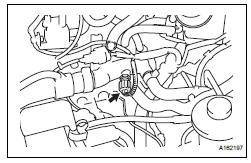

1. DRAIN ENGINE COOLANT (See page CO-6) 2. REMOVE V-BANK COVER SUB-ASSEMBLY (See page EM-28) 3. REMOVE NO. 2 AIR CLEANER INLET (See page EM- 28) 4. REMOVE NO. 1 AIR CLEANER INLET (See page EM- 28) 5. REMOVE AIR CLEANER CAP SUB-ASSEMBLY (See page ES-493) 6. REMOVE AIR CLEANER CASE SUB-ASSEMBLY (See page EM-28) 7. REMOVE ENGINE COOLANT TEMPERATURE SENSOR

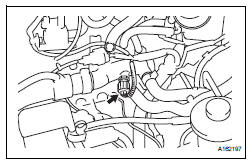

(a) Remove the engine coolant temperature sensor connector.

(b) Remove the engine coolant temperature sensor.

INSPECTION

1. INSPECT ENGINE COOLANT TEMPERATURE SENSOR

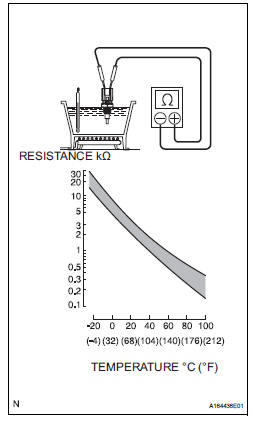

(a) Using an ohmmeter, measure the resistance between the terminals.

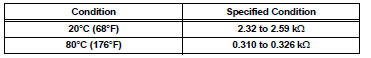

Standard resistance

- If the result is as specified, do not replace the engine coolant temperature sensor

- If the result is not as specified, replace the engine coolant temperature sensor.

| NOTICE: In case of checking the engine coolant temperature sensor in water, do not allow water to go into the terminals. After checking, dry the engine coolant temperature sensor. |

INSTALLATION

1. INSTALL ENGINE COOLANT TEMPERATURE SENSOR

(a) Install the engine coolant temperature sensor.

Torque: 20 N*m (204 kgf*cm, 15 ft.*lbf) (b) Connect the engine coolant temperature sensor connector.

2. INSTALL AIR CLEANER CASE SUB-ASSEMBLY (See page EM-59) 3. INSTALL AIR CLEANER CAP SUB-ASSEMBLY (See page ES-496) 4. INSTALL NO. 1 AIR CLEANER INLET (See page EM- 59) 5. INSTALL NO. 2 AIR CLEANER INLET (See page EM- 60) 6. ADD ENGINE COOLANT (See page CO-7) 7. INSPECT FOR ENGINE COOLANT LEAK (See page CO-1) 8. INSTALL V-BANK COVER SUB-ASSEMBLY (See page EM-63)

Crankshaft position sensor

Crankshaft position sensor

Components

Removal

1. Remove compressor and magnetic clutch

HINT:

(See page AC-227 )

2. REMOVE CRANKSHAFT POSITION SENSOR

(a) Disconnect the crankshaft position sensor

connector.

(b) R ...

Knock sensor

Knock sensor

COMPONENTS

REMOVAL

1. DISCHARGE FUEL SYSTEM PRESSURE

(See page FU-13)

2. REMOVE V-BANK COVER SUB-ASSEMBLY (See

page EM-28)

3. DRAIN ENGINE COOLANT (See page CO-6)

4. REMOVE WINDSHIE ...

Other materials:

Reassembly

1. INSTALL STRAIGHT PIN

(a) Using a plastic hammer, tap in new straight pins to

the cylinder block.

Standard protrusion

2. INSTALL STUD BOLT

(a) Using E8 and E10 "TORX" sockets, install the stud

bolts.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf) for bolt A

17 N*m (173 kgf*cm, ...

Cold Start Idle Air Control System Performance

DESCRIPTION

This monitor will run when the engine is started at -10 to 50°C (14 to 122°F)

of the engine coolant

temperature. The DTC will set after the engine idling for 13 seconds (2 trip

detection logic).

The DTC is designed to monitor the idle air control at cold start. When the

...

Removal

HINT:

Remove the RH by the same procedure as the LH side.

1. REMOVE REAR WHEEL

2. SEPARATE SKID CONTROL SENSOR WIRE

(a) Disconnect the connector from the skid control

sensor.

3. REMOVE REAR BRAKE DRUM SUB-ASSEMBLY (for

Drum Type)

(a) Place matchmarks on the rear brake drum subassembly

a ...