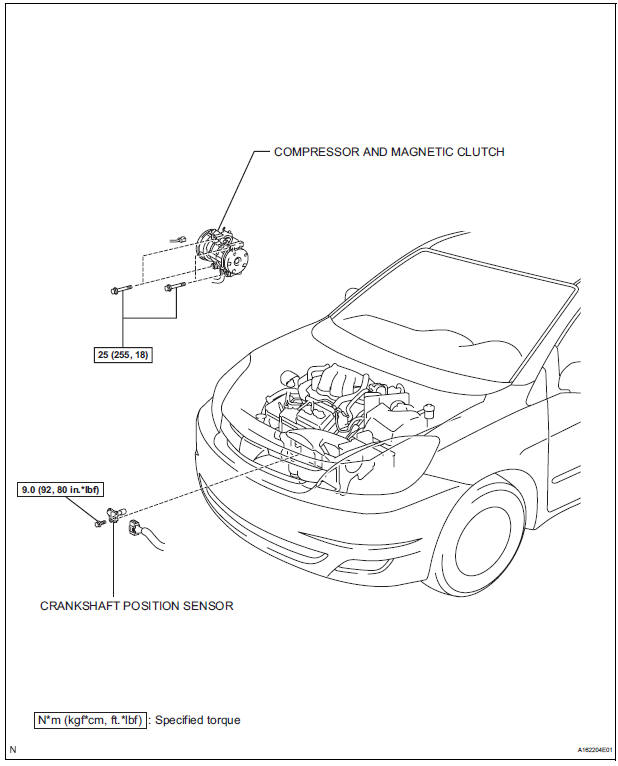

Toyota Sienna Service Manual: Crankshaft position sensor

Components

Removal

1. Remove compressor and magnetic clutch

HINT: (See page AC-227 )

2. REMOVE CRANKSHAFT POSITION SENSOR

(a) Disconnect the crankshaft position sensor connector.

(b) Remove the bolt, and then remove the crankshaft position sensor.

INSPECTION

1. INSPECT CRANKSHAFT POSITION SENSOR

(a) Using an ohmmeter, measure the resistance between the terminals.

Standard resistance

NOTICE:

|

If the resistance is not as specified, replace the crankshaft position sensor.

INSTALLATION

1. INSTALL CRANKSHAFT POSITION SENSOR

(a) Apply a light coat of engine oil to the O-ring on the crankshaft position sensor.

(b) Install the crankshaft position sensor with the bolt.

Torque: 9.0 N*m (92 kgf*cm, 80 in.*lbf) (c) Connect the crankshaft position sensor connector.

2. INSTALL COMPRESSOR AND MAGNETIC CLUTCH

HINT: (See page AC-231)

Vvt sensor

Vvt sensor

COMPONENTS

ON-VEHICLE INSPECTION

1. CHECK VVT SENSOR OUTPUT VOLTAGE

(a) Turn the ignition switch to the ON position.

(b) Check the voltage between the specified terminal

and body grou ...

Engine coolant temperature sensor

Engine coolant temperature sensor

COMPONENTS

REMOVAL

1. DRAIN ENGINE COOLANT (See page CO-6)

2. REMOVE V-BANK COVER SUB-ASSEMBLY (See

page EM-28)

3. REMOVE NO. 2 AIR CLEANER INLET (See page EM-

28)

4. REMOVE NO. 1 AIR CLEAN ...

Other materials:

Locking and unlocking the back door

Entry function (vehicles with a smart key system)

Carry the electronic key to enable this function.

Press the unlock button to

unlock all the doors.

The door cannot be unlocked for

3 seconds after the door is

locked.

Lock the back door again when

you leave the vehicle. The back

...

How to proceed with

troubleshooting

HINT:

*: Use the intelligent tester.

1 VEHICLE BROUGHT TO WORKSHOP

2 CUSTOMER PROBLEM ANALYSIS

(a) Confirm problem symptoms

3 CHECK MULTIPLEX COMMUNICATION SYSTEM*

Check if the multiplex communication system DTC is output.

HINT:

The center airbag sensor assembly of this system ...

Installation

1. INSTALL REAR DOOR GLASS WEATHERSTRIP

Install the rear door glass weatherstrip.

2. INSTALL SLIDE DOOR WINDOW ASSEMBLY

3. INSTALL REAR DOOR GLASS RUN

4. INSTALL REAR DOOR TRIM BOARD SUBASSEMBLY

5. INSTALL SIDE TRIM BOARD COVER REAR

6. INSTALL REAR DOOR WINDOW FRAME SUBASSEMBLY

7. INSTA ...