Toyota Sienna Service Manual: Engine front oil seal

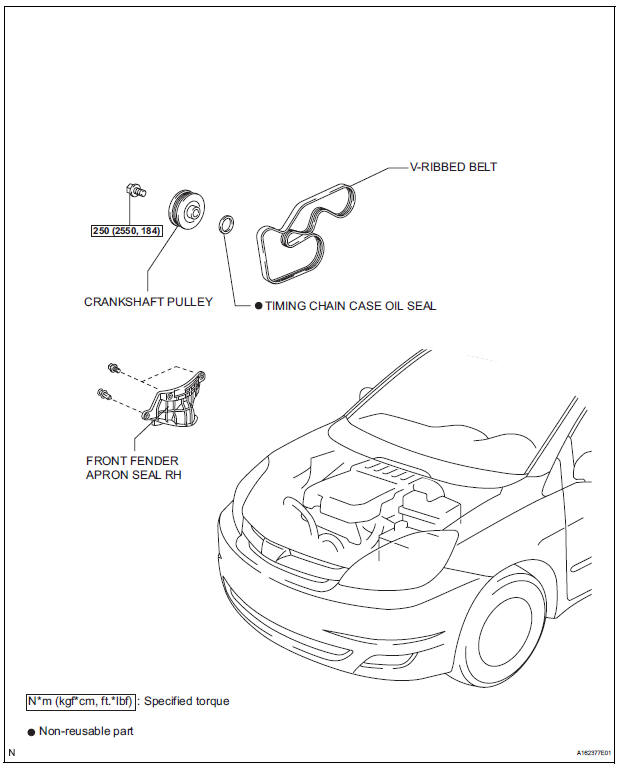

COMPONENTS

REMOVAL

1. REMOVE FRONT WHEEL RH 2. REMOVE FRONT FENDER APRON SEAL RH (See page EM-26) 3. REMOVE V-RIBBED BELT (See page EM-6) 4. REMOVE CRANKSHAFT PULLEY

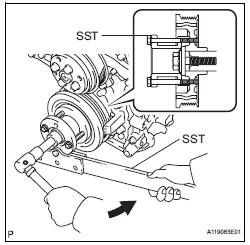

(a) Using SST, loosen the crankshaft pulley bolt.

SST 09213-70011 (09213-70020), 09330-00021

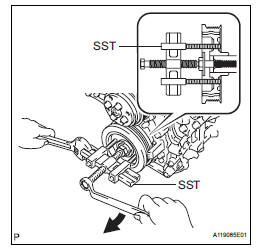

(b) Using SST, remove the crankshaft pulley bolt and crankshaft pulley.

SST 09950-50013 (09951-05010, 09952-05010, 09953-05020, 09954-05021)

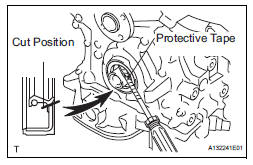

5. REMOVE TIMING CHAIN CASE OIL SEAL

(a) Using a screwdriver, pry out the oil seal.

HINT:

Tape the screwdriver tip before use.

| NOTICE: After the removal, check the crankshaft for damage. If it is damaged, smooth the surface with 400-grit sandpaper. |

INSTALLATION

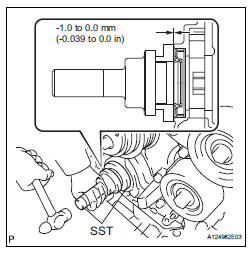

1. INSTALL TIMING CHAIN CASE OIL SEAL

(a) Apply MP grease to a new oil seal lip.

(b) Using SST and a hammer, tap in the oil seal until its surface is flush with the timing chain cover edge.

SST 09223-22010, 09506-35010

NOTICE:

|

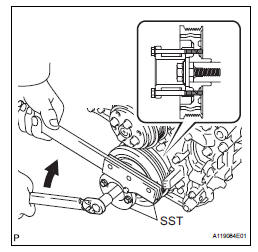

2. INSTALL CRANKSHAFT PULLEY

(a) Align the pulley set key with the key groove of the pulley, and slide on the pulley.

(b) Using SST, install the pulley bolt.

SST 09213-70011 (09213-70020), 09330-00021 Torque: 250 N*m (2550 kgf*cm, 184 ft.*lbf)

3. INSTALL V-RIBBED BELT (See page EM-7) 4. INSTALL FRONT FENDER APRON SEAL RH (See page EM-62) 5. INSTALL FRONT WHEEL RH Torque: 103 N*m (1050 kgf*cm, 76 ft.*lbf)

Drive belt

Drive belt

COMPONENTS

REMOVAL

1. REMOVE FRONT WHEEL RH

2. REMOVE FRONT FENDER APRON SEAL RH (See

page EM-26)

3. REMOVE V-RIBBED BELT

(a) Using SST, release the belt tension by turning the

belt tensi ...

Engine rear oil seal

Engine rear oil seal

Components

Removal

1. REMOVE AUTOMATIC TRANSAXLE ASSEMBLY (for

2WD)

HINT:

See page AX-163.

2. REMOVE AUTOMATIC TRANSAXLE ASSEMBLY (for

4WD)

HINT:

See page AX-167.

3. REMOVE DRIVE PLATE A ...

Other materials:

Improper Aiming of Radar Sensor Beam Axis

DTC P1572 Improper Aiming of Radar Sensor Beam Axis

DESCRIPTION

This DTC is output when the scanning angle of the laser sensor is incorrect.

This DTC is also output when

the laser sensor beam axis is determined to be in an incorrect position.

DTC No.

DTC Detection Condition

...

Front passenger side power

window switch

Inspection

1. INSPECT POWER WINDOW REGULATOR SWITCH ASSEMBLY

Check the resistance between the switch terminals

when the switch is operated.

Standard

If the result is not as specified, replace the switch

assembly. ...

Operation check

1. DETECTION RANGE MEASUREMENT AND INDICATOR CHECK

Turn the IG switch ON.

Move the shift lever to the R position (when the back

sonar and rear clearance sonar is checked).

With front clearance sonar:

Move the shift lever to the N position (when the front

clearance son ...