Toyota Sienna Service Manual: Engine rear oil seal

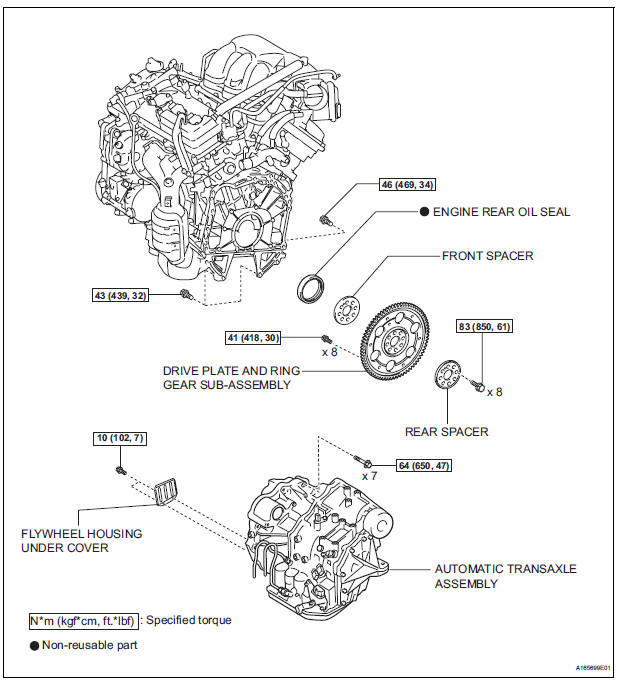

Components

Removal

1. REMOVE AUTOMATIC TRANSAXLE ASSEMBLY (for 2WD)

HINT:

See page AX-163.

2. REMOVE AUTOMATIC TRANSAXLE ASSEMBLY (for 4WD)

HINT: See page AX-167.

3. REMOVE DRIVE PLATE AND RING GEAR SUBASSEMBLY

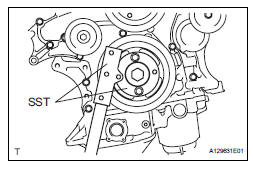

(a) Using SST, hold the crankshaft.

SST 09213-70011 (09213-70020), 09330-00021

(b) Remove the 8 bolts, front spacer, drive plate and rear spacer.

4. REMOVE ENGINE REAR OIL SEAL

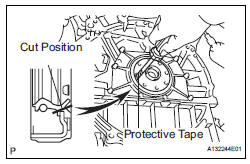

(a) Using a knife, cut off the oil seal lip.

(b) Using a screwdriver, pry out the oil seal.

NOTICE:

Be careful not to damage the crankshaft. Tape the screwdriver tip before use.

INSTALLATION

1. INSTALL ENGINE REAR OIL SEAL

(a) Apply MP grease to a new oil seal lip.

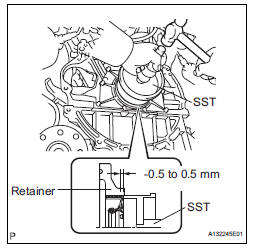

(b) Using SST and a hammer, tap in the oil seal.

SST 09223-15030, 09950-70010 (09951-07150) Oil seal tap in depth: -0.5 to 0.5 mm (-0.020 to 0.020 in.)

2. INSTALL DRIVE PLATE AND RING GEAR SUBASSEMBLY

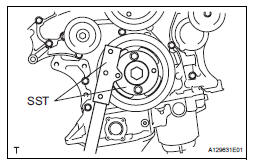

(a) Using SST, hold the crankshaft.

SST 09213-70011 (09213-70020), 09330-00021

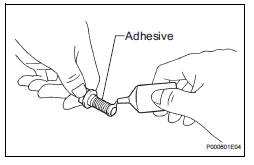

(b) Apply adhesive to 2 or 3 threads of the mounting bolt end.

Adhesive: Part No. 08833-00070, THREE BOND 1324 or equivalent

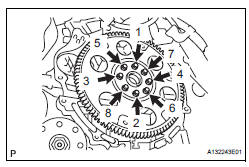

(1) Install the front spacer, drive plate and rear spacer on the crankshaft.

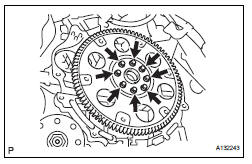

(2) Install and tighten the 8 mounting bolts uniformly in several steps.

Torque: 83 N*m (850 kgf*cm, 61 ft.*lbf)

3. INSTALL AUTOMATIC TRANSAXLE ASSEMBLY (for 2WD)

HINT:

See page AX-166.

4. INSTALL AUTOMATIC TRANSAXLE ASSEMBLY (for 4WD)

HINT:

See page AX-167.

Engine front oil seal

Engine front oil seal

COMPONENTS

REMOVAL

1. REMOVE FRONT WHEEL RH

2. REMOVE FRONT FENDER APRON SEAL RH (See

page EM-26)

3. REMOVE V-RIBBED BELT (See page EM-6)

4. REMOVE CRANKSHAFT PULLEY

(a) Using SST, loos ...

Engine assembly

Engine assembly

Components

REMOVAL

1. DISCHARGE FUEL SYSTEM PRESSURE (See page

FU-13)

2. DISCHARGE REFRIGERANT FROM

REFRIGERATION SYSTEM (See page AC-172)

3. REMO ...

Other materials:

Removal and installation of fuel control parts

(a) PLACE FOR REMOVING AND INSTALLING FUEL

SYSTEM PARTS

(1) Work in a location with good air ventilation that

does not have welders, grinders, drills, electric

motors, stoves, or any other ignition sources.

(2) Never work in a pit or near a pit as vaporized

fuel will collect in those places. ...

On-vehicle inspection

1. CHECK AUTO SLIDE-OPEN / CLOSE FUNCTION

Check that the sliding roof switch can operate the

sliding roof glass as follows while the tilt-up / DOWN

function is not operating.

Standard

HINT:

The sliding roof stops partway when the sliding roof

switch is pushed on either side during AU ...

Indicator Circuit

DESCRIPTION

This system has two indicator lights. One of the indicator lights is built

into the fold seat switch. This

indicator light receives power from the fold seat control ECU. It comes on or

blinks when the system

detects that an object is caught or when the seat operation conditions ar ...