Toyota Sienna Service Manual: Fuel Receiver Gauge Malfunction

DESCRIPTION

The meter CPU uses the fuel sender gauge assembly to determine the level of the fuel in the fuel tank.

The resistance of the fuel sender gauge will vary between approximately 15 Ω with the float at the full position, and 410 Ω with the float at the empty position. The meter outputs battery voltage through two 820 Ω resistors that are mounted in parallel inside the meter ECU. The meter CPU measures the voltage between the variable resistor in the fuel sender gauge and the two resistors mounted in parallel in the meter. Voltage measured at this point will vary as the float of the fuel sender gauge is moved. The highest voltage observed should be approximately half of battery voltage.

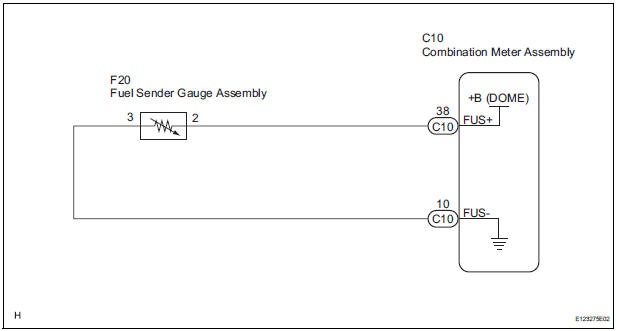

WIRING DIAGRAM

INSPECTION PROCEDURE

1 PERFORM ACTIVE TEST BY INTELLIGENT TESTER

- Connect the intelligent tester to the DLC3.

- Turn the ignition switch to the ON position.

- Turn the tester ON.

- Enter following menus: DIAGNOSIS / OBD/MOBD / METER / ACTIVE TEST.

- Check the operation by referring to the values in the table below.

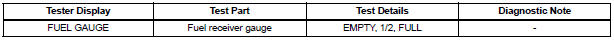

METER:

OK: Needle indication is normal.

2 READ VALUE OF INTELLIGENT TESTER

- Connect the intelligent tester to the DLC3.

- Turn the ignition switch to the ON position.

- Turn the tester ON.

- Enter following menus: DIAGNOSIS / OBD/MOBD / METER / DATA LIST.

- Check the values by referring to the values in the table below

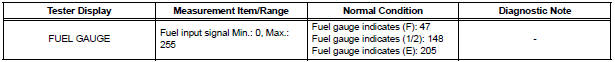

METER:

OK: Fuel value signal displayed on the tester is almost the same as needle indication

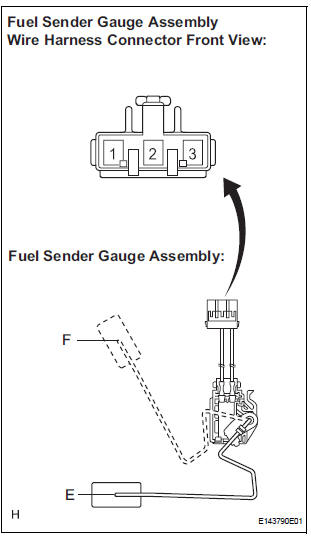

3 INSPECT FUEL SENDER GAUGE ASSEMBLY

- Disconnect the connector from the fuel sender gauge.

- Check the the float moves smoothly between F and E.

- Measure the resistance between terminals 1 and 2 of the connector according to the value(s) in the table below.

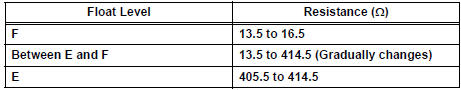

Standard resistance: Fuel sender gauge

4 CHECK HARNESS AND CONNECTOR (COMBINATION METER ASSEMBLY - FUEL SENDER GAUGE ASSEMBLY)

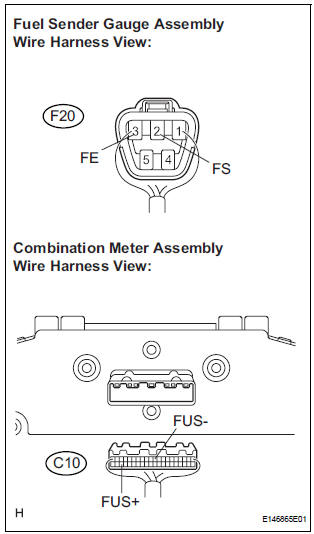

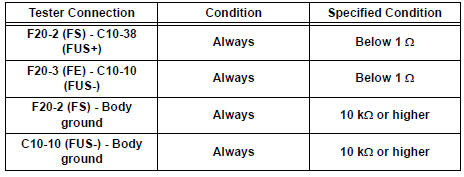

- Disconnect the F20 and C10 connectors.

- Measure the resistance according to the value(s) in the table below.

Standard resistance

REPLACE COMBINATION METER ASSEMBLY

Tachometer Malfunction

Tachometer Malfunction

DESCRIPTION

The meter CPU receives the engine revolution signal from the ECM via the

direct lines. The meter CPU

displays engine revolution data that is calculated based on the data received

fro ...

Engine Coolant Temperature Receiver Gauge Malfunction

Engine Coolant Temperature Receiver Gauge Malfunction

DESCRIPTION

The meter CPU receives engine coolant temperature signals from the ECM via

the multiplex

communication lines. The meter CPU displays engine coolant temperature that is

calculated bas ...

Other materials:

Check for intermittent

problems

1. CHECK FOR INTERMITTENT PROBLEMS

HINT:

For use of the intelligent tester only:

Inspect the vehicle's ECM using check mode.

Intermittent problems are easier to detect with an

intelligent tester when the ECM is in check mode. In

check mode, the ECM uses 1 trip detection logic, which

is more ...

Headlight dimmer switch

COMPONENTS

REMOVAL

1. REMOVE STEERING COLUMN LOWER COVER

2. REMOVE STEERING COLUMN UPPER COVER

3. REMOVE HEADLIGHT DIMMER SWITCH ASSEMBLY

Disconnect the connector.

Release the claw fitting and remove the headlight

dimmer switch assembly.

INSPECTION

1. HEADLIGHT DI ...

Mass or Volume Air Flow Circuit/ Mass or Volume Air Flow Circuit Low Input/

Mass or Volume Air Flow Circuit High Input

DESCRIPTION

The Mass Air Flow (MAF) meter is a sensor that measures the amount of air

flowing through the throttle

valve. The ECM uses this information to determine the fuel injection time and to

provide appropriate airfuel

ratio. Inside the MAF meter, there is a heated platinum wire which is ...