Toyota Sienna Service Manual: Tachometer Malfunction

DESCRIPTION

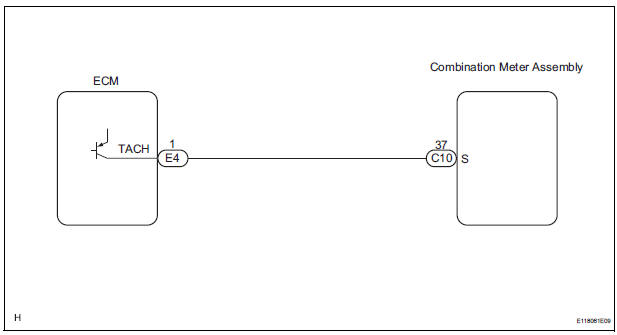

The meter CPU receives the engine revolution signal from the ECM via the direct lines. The meter CPU displays engine revolution data that is calculated based on the data received from the ECM.

WIRING DIAGRAM

INSPECTION PROCEDURE

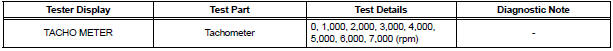

1 PERFORM ACTIVE TEST BY INTELLIGENT TESTER

- Connect the intelligent tester to the DLC3.

- Turn the switch to the ON position.

- Turn the tester ON.

- Enter the following menus: DIAGNOSIS / OBD/MOBD / METER / ACTIVE TEST.

- Check the operation by referring to the values in the table below.

METER:

OK: Needle indication is normal.

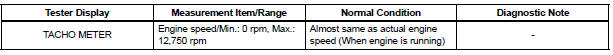

2 READ VALUE OF INTELLIGENT TESTER (ENGINE SPEED SIGNAL)

- Connect the intelligent tester to the DLC3.

- Turn the switch to the ON position.

- Turn the tester ON.

- Enter the following menus: DIAGNOSIS / OBD/MOBD / METER / DATA LIST.

- Check the values by referring to the values in the table below

METER:

OK: Engine speed displayed on the tester is almost the same as the actual engine speed.

REPLACE COMBINATION METER ASSEMBLY

3 READ VALUE OF INTELLIGENT TESTER (ENGINE SPEED SIGNAL)

- Connect the intelligent tester to the DLC3.

- Turn the switch to the ON position.

- Turn the tester ON.

- Enter the following menus: DIAGNOSIS / OBD/MOBD / ENGINE / ACTIVE TEST.

- Check the values by referring to the values in the table below.

ENGINE:

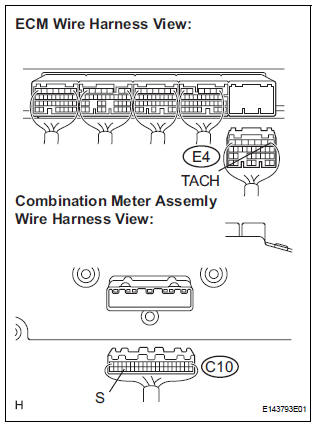

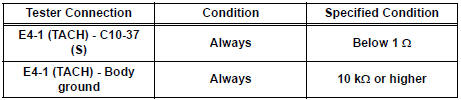

4 CHECK HARNESS AND CONNECTOR (COMBINATION METER - ECM)

- Disconnect the E4 and C10 connectors.

- Measure the resistance according to the value(s) in the table below.

Standard resistance

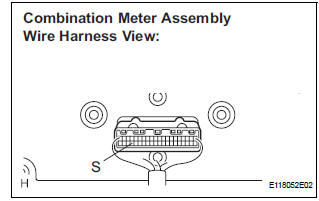

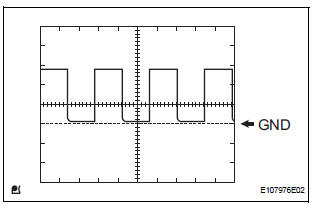

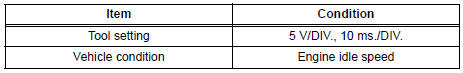

5 INSPECT COMBINATION METER ASSEMBLY

- Check the input signal waveform.

- Remove the combination meter with the connector still connected.

- Connect the oscilloscope to terminal C10-37 (S) and body ground.

- Start the engine.

- Check the signal waveform according to the condition(s) in the table below.

OK: The waveform is displayed as shown in the illustration

REPLACE ECM

Speedometer Malfunction

Speedometer Malfunction

DESCRIPTION

Factors that affect the indicated vehicle speed include tire size, tire

inflation, and tire wear. The speed indicated on the speedometer has an

allowable margin of error. This can be ...

Fuel Receiver Gauge Malfunction

Fuel Receiver Gauge Malfunction

DESCRIPTION

The meter CPU uses the fuel sender gauge assembly to determine the level of

the fuel in the fuel tank.

The resistance of the fuel sender gauge will vary between approximately 15 ] ...

Other materials:

Terminals of ECU

1. CENTER AIRBAG SENSOR ASSEMBLY (w/ Side

Airbag)

2. CENTER AIRBAG SENSOR ASSEMBLY (w/o Side

Airbag)

...

Disassembly

1. REMOVE BACK DOOR GARNISH CENTER

Using a clip remover, disengage the 5 clips and

remove the garnish center.

2. REMOVE BACK DOOR SIDE GARNISH LH

Using a clip remover, disengage the 3 clips and

remove the side garnish.

3. REMOVE BACK DOOR SIDE GARNISH RH

Using a clip remove ...

Short to GND in Curtain Shield Squib LH Circuit

DTC B1167/85 Short to GND in Curtain Shield Squib LH Circuit

DESCRIPTION

The curtain shield squib LH circuit consists of the center airbag sensor

assembly and the curtain shield

airbag assembly LH.

The circuit instructs the SRS to deploy when deployment conditions are met.

DTC B1167/85 is ...