Toyota Sienna Service Manual: Installation

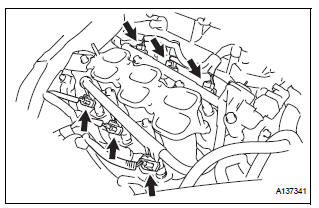

1. INSTALL FUEL INJECTOR ASSEMBLY

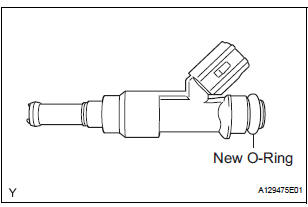

(a) Apply a light coat of spindle oil or gasoline to new Orings, and install them to each injector.

(b) Apply a light coat of spindle oil or gasoline where the fuel delivery pipe contacts the O-ring.

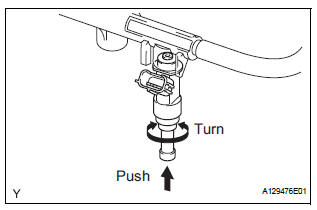

(c) Push the fuel injector while turning it to install the injector in the fuel delivery pipe.

(d) Position the fuel injector connector outward.

NOTICE:

|

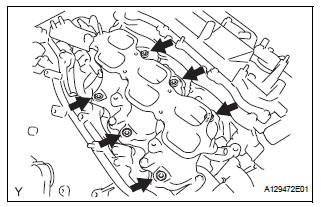

(e) Install 6 new insulators to the intake manifold.

(f) Place the fuel delivery pipe which has the 6 fuel injectors installed to it in position on the intake manifold.

| NOTICE: Be careful not to drop the fuel injectors when installing the fuel delivery pipe. |

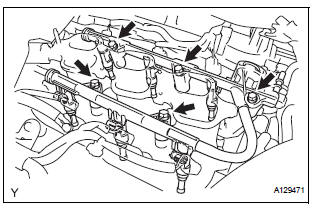

(g) Temporarily install the 5 bolts which are used to hold the fuel delivery pipe to the intake manifold.

| NOTICE: After installing the fuel injectors, check that they turn smoothly. If not, reinstall the injectors with new O-rings. |

(h) Tighten the 5 bolts which are used to hold the fuel delivery pipe to the intake manifold.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

(i) Connect the 6 fuel injector connectors.

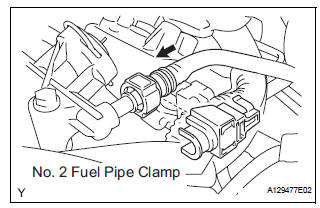

2. CONNECT FUEL TUBE SUB-ASSEMBLY

(a) Push in the tube connector onto the pipe until the tube connector makes a "click" sound.

NOTICE:

|

(b) Install the No. 2 fuel pipe clamp.

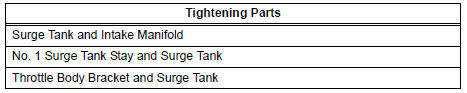

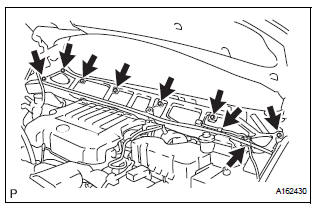

3. INSTALL INTAKE AIR SURGE TANK ASSEMBLY

NOTICE:

DO NOT apply oil to the bolts listed below:

|

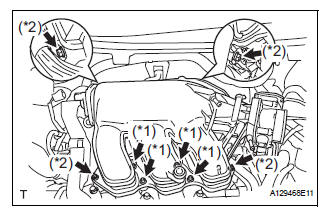

(a) Install a new gasket to the intake air surge tank assembly.

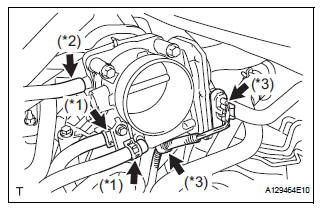

(b) Using a 5 mm hexagon socket wrench, install the 4 bolts. (*1) Torque: 18 N*m (184 kgf*cm, 13 ft.*lbf) (c) Install the intake air surge tank assembly with the 2 nuts and 2 bolts. (*2)

Torque: Nut 16 N*m (163 kgf*cm, 12 ft.*lbf) Bolt 21 N*m (214 kgf*cm, 15 ft.*lbf)

(d) Connect the connector.

(e) Connect the union to check valve hose. (*1) (f) Connect the No. 1 ventilation hose. (*2)

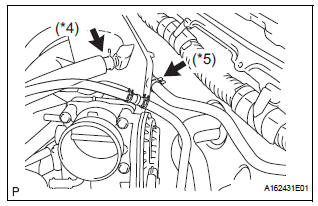

(g) Install the clamp and connect the throttle with motor body assembly connector. (*3) (h) Connect the vapor feed hose assembly. (*4) (i) Connect the 2 water by-pass hoses to the throttle with motor body assembly. (*5)

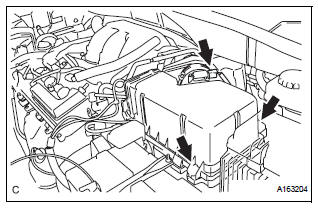

4. INSTALL AIR CLEANER CAP SUB-ASSEMBLY

(a) Install the 2 bolts and air cleaner cap sub-assembly.

(b) Connect the No. 2 ventilation hose and air cleaner hose band.

(c) Connect the vacuum hose (EVAP) to the air cleaner hose.

(d) Connect the 3 vacuum hoses.

5. ADD ENGINE COOLANT (See page CO-7)

6. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL 7. INSPECT FOR ENGINE COOLANT LEAK (See page CO-1) 8. INSTALL NO. 1 ENGINE UNDER COVER 9. INSPECT FOR FUEL LEAK (See page FU-7)

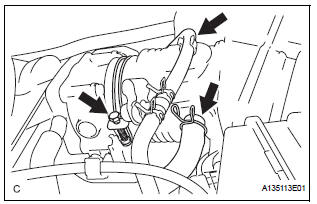

10. INSTALL V-BANK COVER SUB-ASSEMBLY (See page EM-63) 11. INSTALL COWL TOP PANEL SUB-ASSEMBLY OUTER FRONT

(a) Install the 7 bolts and the cowl top panel subassembly outer front.

Torque: 7.5 N*m (76 kgf*cm, 66 in.*lbf) (b) Connect the fuel pump resistor connector.

(c) Connect the wire harness clamp.

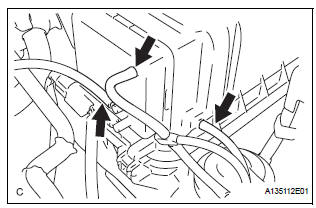

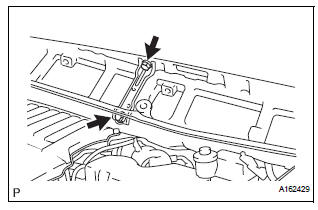

12. INSTALL NO. 1 COWL TOP TO COWL BRACE INNER

(a) Install the 2 bolts and the No.1 cowl top to cowl brace inner.

Torque: 7.5 N*m (76 kgf*cm, 66 in.*lbf)

13. INSTALL WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY (See page WW-6) 14. INSTALL FRONT WIPER ARM LH (See page WW-6) 15. INSTALL FRONT WIPER ARM RH (See page WW-7)

Inspection

Inspection

1. INSPECT FUEL INJECTOR ASSEMBLYV

(A) inspect the injector resistance.

(1) Using an ohmmeter, measure the resistance

between the terminals.

Standard resistance

If the resistance is not a ...

Other materials:

Rear Occupant Classification Sensor LH Circuit

Malfunction

DTC B1782 Rear Occupant Classification Sensor LH Circuit

Malfunction

DESCRIPTION

The rear occupant classification sensor LH circuit consists of the occupant

classification ECU and the rear

occupant classification sensor LH.

DTC B1782 is recorded when a malfunction is detected in the rear oc ...

Installation

1. INSTALL HEATED OXYGEN SENSOR (for Bank 2

Sensor 2)

(a) Using SST, install the heated oxygen sensor to the

front exhaust pipe.

SST 09224-00010

Torque: 40 N*m (408 kgf*cm, 30 ft.*lbf) for use

with SST

44 N*m (449 kgf*cm, 32 ft.*lbf) for use

without SST

HINT:

Use a torque wrench wit ...

Push Switch / Key Unlock Warning Switch Malfunction

DTC B2780 Push Switch / Key Unlock Warning Switch Malfunction

DESCRIPTION

This DTC will be output if the transponder key ECU does not detect that the

unlock warning switch is on

even when the ignition switch is on (Under the normal conditions, the unlock

warning switch is on when

the ignitio ...