Toyota Sienna Service Manual: Inspection

1. INSPECT FUEL INJECTOR ASSEMBLYV

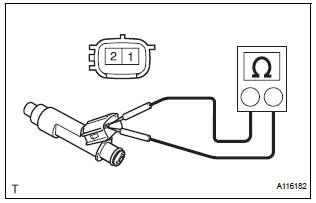

(A) inspect the injector resistance.

(1) Using an ohmmeter, measure the resistance between the terminals.

Standard resistance

If the resistance is not as specified, replace the injector.

(b) Inspect the injection volume.

| CAUTION:

This test involves high-pressure fuel and

electricity. Take every precaution regarding the

safe handling of both fuel and electricity.

Perform this test in a safe area, and avoid any sparks or flames. Do not smoke. |

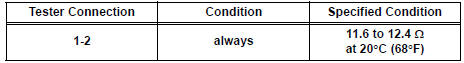

(1) Install the fuel tube connector to SST (hose), then connect the tube connector to the fuel pipe (vehicle side).

SST 09268-31011 (09268-41500, 90467- 13001, 95336-08070)

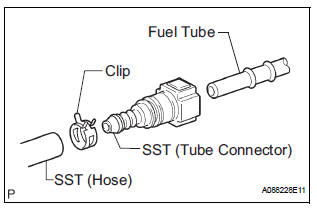

(2) Install the O-ring to the fuel injector subassembly.

(3) Connect SST (adaptor and hose) to the injector, and hold the injector and union with SST (clamp).

SST 09268-31011 (90467-13001, 95336- 08070), 09268-41140, 09268-41400

(4) Put the injector into the graduated cylinder.

| CAUTION: Install a suitable vinyl tube onto the injector to contain gasoline spray. |

(5) Operate the fuel pump (See page FU-7).

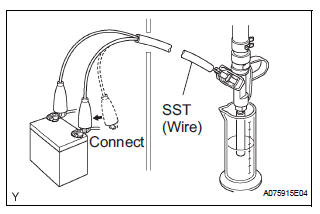

(6) Connect SST (wire) to the injector and the battery for 15 seconds, and measure the injection volume with the graduated cylinder.

Test each injector 2 or 3 times.

SST 09842-30080

Volume: 84 to 100 cm3 (5.1 to 6.0 cu in.) in 15 seconds

Difference between each injector: 16 cm3 (0.98 cu in.) or less

If the injection volume is not as specified, replace the injector.

(c) Check for leakage.

(1) In the condition above, disconnect the tester probes of SST (wire) from the battery and check for fuel leakage from the injector.

Fuel drop: 1 drop or less in 16 minutes

Removal

Removal

1. DISCHARGE FUEL SYSTEM PRESSURE

HINT:

See page FU-1.

2. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

3. REMOVE NO. 1 ENGINE UNDER COVER

4. DRAIN ENGINE COOLANT (See page CO-6)

5. REMOVE FR ...

Installation

Installation

1. INSTALL FUEL INJECTOR ASSEMBLY

(a) Apply a light coat of spindle oil or gasoline to new Orings,

and install them to each injector.

(b) Apply a light coat of spindle oil or gasoline where ...

Other materials:

Speaker Circuit

DESCRIPTION

When the vehicle has a built-in type amplifier, a sound signal is

sent from the radio receiver to the

speakers via the "6 Speaker System" circuit.

When the vehicle has a separate type amplifier, a sound signal

from the radio receiver is amplified by

...

Customize parameters

HINT:

The following items can be customized.

NOTICE:

After confirming whether the items requested by the

customer are applicable or not for customization,

perform the customize operation.

Be sure to record the current settings before

customizing.

When troubleshootin ...

Map Display Incomplete

INSPECTION PROCEDURE

1 CHECK MAP DISC

Check that the map disc is not deformed or cracked.

OK:

No deformations or cracks on map disc.

2 CHECK DISPLAY

Check that displays other than the navigation display are

complete.

OK:

No other incomplete displays are found.

REPLACE RADIO ...