Toyota Sienna Service Manual: Installation

1. Install generator assembly

(a) Install the bracket with the bolt.

Torque: 20 N*m (204 kgf*cm, 15 ft.*lbf)

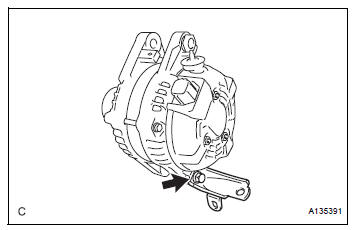

(b) Install the wire harness clamp stay.

Torque: 8.4 N*m (86 kgf*cm, 74 in.*lbf)

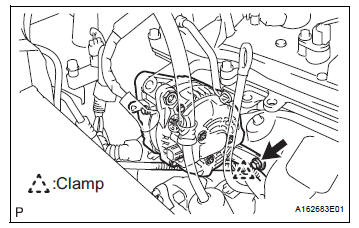

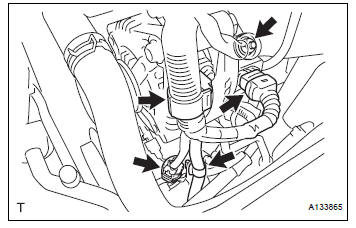

(c) Connect the wire harness clamp.

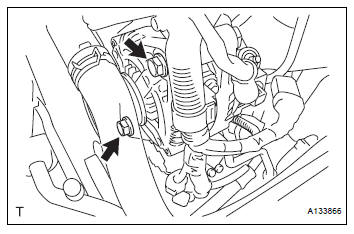

(d) Install the generator assembly to the cylinder block with the bolt.

Torque: 20 N*m (204 kgf*cm, 15 ft.*lbf)

(e) Install the 2 bolts.

Torque: 43 N*m (438 kgf*cm, 32 ft.*lbf)

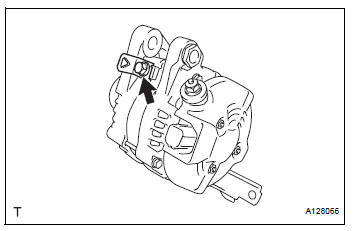

Connect the generator connector to the generator assembly.

(g) Install the generator wire with the nut.

Torque: 9.8 N*m (100 kgf*cm, 87 in.*lbf) (h) Install the terminal cap.

(i) Connect the 2 wire harness clamps.

(j) Connect the magnetic clutch connector to the compressor and magnetic clutch.

2. INSTALL V-RIBBED BELT (See page EM-7) 3. INSTALL RADIATOR ASSEMBLY WITH FAN SHROUD AND FAN MOTOR (See page CO-40) 4. INSTALL NO. 1 RADIATOR SUPPORT (See page CO- 40) 5. INSTALL RADIATOR SUPPORT CUSHION (See page CO-41) 6. REMOVE PRESSURE FEED TUBE ASSEMBLY (See page CO-41) 7. INSTALL HEADLIGHT BRACKET RH (See page CO- 41) 8. INSTALL RADIATOR SIDE DEFLECTOR RH (See page CO-41) 9. INSTALL HEADLIGHT ASSEMBLY RH (See page LI- 78) 10. CONNECT NO. 2 OIL COOLER OUTLET TUBE SUBASSEMBLY (See page CO-41) 11. INSTALL RADIATOR UPPER SUPPORT SUBASSEMBLY (See page CO-42) 12. CONNECT COOLING FAN ECU CONNECTOR (See page CO-42) 13. INSTALL HOOD LOCK SUPPORT SUB-ASSEMBLY (See page CO-43) 14. INSTALL HOOD LOCK ASSEMBLY (See page CO-43) 15. INSTALL HOOD LOCK RELEASE LEVER PROTECTOR (See page CO-44) 16. CONNECT NO. 2 RADIATOR HOSE (See page CO-44) 17. CONNECT NO. 1 RADIATOR HOSE (See page CO-44)

18. CONNECT RADIATOR RESERVE TANK HOSE OR PIPE (See page CO-44) 19. INSTALL NO. 1 AIR CLEANER INLET (See page EM- 59) 20. INSTALL FRONT BUMPER ENERGY ABSORBER 21. INSTALL FRONT BUMPER ASSEMBLY (See page ET- 9) 22. INSTALL BATTERY (See page EM-59) 23. INSTALL NO. 2 AIR CLEANER INLET (See page EM- 60) 24. ADD ENGINE COOLANT (See page CO-7) 25. INSPECT FOR COOLANT LEAK (See page CO-1) 26. ADD AUTOMATIC TRANSAXLE FLUID 27. CHECK AUTOMATIC TRANSAXLE FLUID (See page AX-123) 28. INSTALL FRONT FENDER APRON SEAL RH (See page EM-62) 29. INSTALL NO. 1 ENGINE UNDER COVER (See page EM-63) 30. INSTALL FRONT WHEEL RH Torque: 103 N*m (1050 kgf*cm, 76 ft.*lbf) 31. INSTALL V-BANK COVER SUB-ASSEMBLY (See page EM-63) 32. VEHICLE PREPARATION FOR HEADLIGHT AIM ADJUSTMENT (See page LI-71) 33. PREPARATION FOR HEADLIGHT AIMING (Using a tester) (See page LI-71) 34. PREPARATION FOR HEADLIGHT AIMING (Using a Screen) (See page LI-72)

35. HEADLIGHT AIMING INSPECTION (See page LI-74) 36. HEADLIGHT AIMING ADJUSTMENT (See page LI-75) 37. VEHICLE PREPARATION FOR FOG LIGHT AIM ADJUSTMENT (w/ Fog Light) (See page LI-82) 38. PREPARATION FOR FOG LIGHT AIMING (Using a Screen) (w/ Fog Light) (See page LI-83) 39. FOG LIGHT AIMING INSPECTION (w/ Fog Light) (See page LI-74) 40. FOG LIGHT AIMING ADJUSTMENT (w/ Fog Light) (See page LI-85)

Reassembly

Reassembly

1. INSTALL GENERATOR ROTOR ASSEMBLY

(a) Place the drive end frame on the clutch pulley.

(b) Install the generator rotor assembly to the drive end

frame.

(c) Place a new generator washer ...

Other materials:

Setting the vehicle speed

Press the “ON-OFF” button to

activate the cruise control.

Cruise control indicator will come

on*1 or will be displayed on the

multi-information display*2.

Press the button again to deactivate

the cruise control.

Accelerate or decelerate the

vehicle to the desired s ...

On-vehicle inspection

1. INSPECT CAMSHAFT TIMING CONTROL VALVE ASSEMBLY

Connect the intelligent tester to the DLC3.

Turn the ignition switch to the ON position.

Start the engine and warm it up.

Select the intelligent tester from the ACTIVE TEST

menu.

Check the engine speed ...

Checking monitor status

The purpose of the monitor result (mode 06) is to allow

access to the results for on-board diagnostic monitoring tests

of specific components/systems that are not continuously

monitored. Examples are catalyst, evaporative emission

(EVAP) and thermostat.

The monitor result allows the OBD II sc ...