Toyota Sienna Service Manual: Reassembly

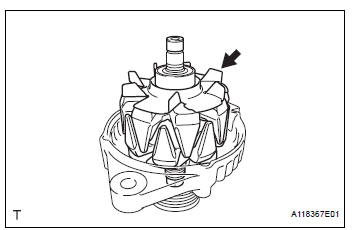

1. INSTALL GENERATOR ROTOR ASSEMBLY

(a) Place the drive end frame on the clutch pulley.

(b) Install the generator rotor assembly to the drive end frame.

(c) Place a new generator washer on the generator rotor.

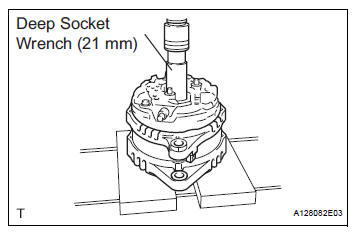

2. INSTALL GENERATOR COIL ASSEMBLY

(a) Using a deep socket wrench (21 mm) and a press, slowly press in the generator coil assembly.

(b) Install the 4 bolts.

Torque: 5.8 N*m (59 kgf*cm, 51 in.*lbf)

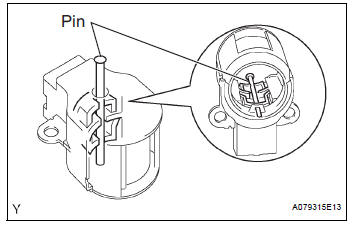

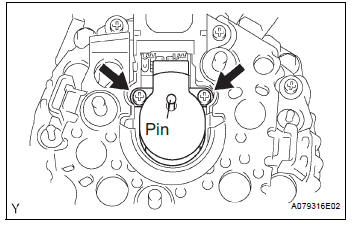

3. INSTALL GENERATOR BRUSH HOLDER ASSEMBLY

(a) While pushing the 2 brushes into the generator brush holder assembly, insert a φ1.0 mm (0.039 in.) pin into the brush holder hole.

(b) Install the brush holder assembly to the generator coil with the 2 screws.

Torque: 1.8 N*m (18 kgf*cm, 16 in.*lbf) (c) Pull out the pin from the generator brush holder.

4. INSTALL GENERATOR TERMINAL INSULATOR

(a) Install the terminal insulator to the generator coil.

| NOTICE: Pay attention to installation direction of the terminal insulator. |

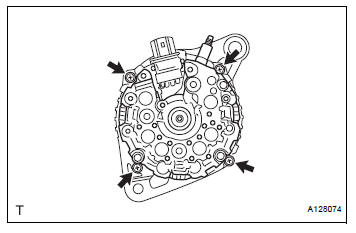

5. INSTALL GENERATOR REAR END COVER

(a) Install the generator rear end cover to the generator coil with the 3 nuts.

Torque: 4.6 N*m (47 kgf*cm, 41 in.*lbf)

6. INSTALL GENERATOR CLUTCH PULLEY

(a) Temporarily install the clutch pulley onto the rotor shaft.

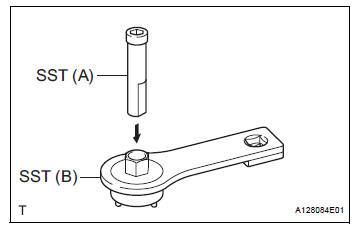

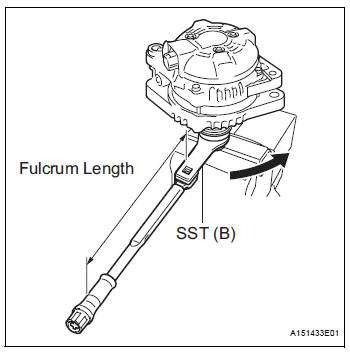

(b) Set SST (A) and (B).

SST 09820-63020

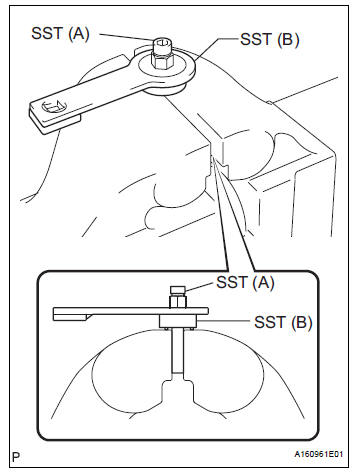

(c) Clamp SST (A) in a vise.

| NOTICE: Be sure to fix the flat surface of SST (A) in a vise. |

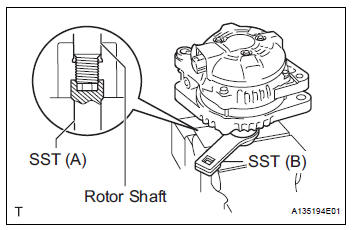

(d) Place the rotor shaft end into SST (A).

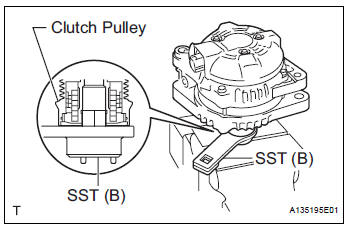

(e) Fit SST (B) to the clutch pulley.

(f) Tighten the pulley by turning SST (B) in the direction shown in the illustration.

Torque: without SST 110 N*m (1125 kgf*cm, 81 ft.*lbf)

with SST 84 N*m (857 kgf*cm, 62 ft.*lbf)

NOTICE:

|

(g) Remove the generator assembly from SST.

(h) Check that the clutch pulley rotates smoothly.

(i) Install a new clutch pulley cap to the clutch pulley.

Replacement

Replacement

1. REPLACE GENERATOR DRIVE END FRAME BEARING

(a) Remove the 4 screws and retainer plate from the

drive end frame.

(b) Using SST and a hammer, tap out the drive end

frame bearing from the d ...

Installation

Installation

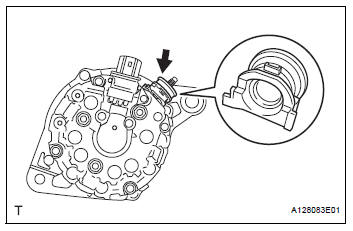

1. Install generator assembly

(a) Install the bracket with the bolt.

Torque: 20 N*m (204 kgf*cm, 15 ft.*lbf)

(b) Install the wire harness clamp stay.

Torque: 8.4 N*m (86 kgf*cm, 74 in. ...

Other materials:

Data list / active test

HINT:

By accessing the DATA LIST displayed by the intelligent

tester, you can perform such functions as reading the values

of switches and sensors without removing any parts. Reading

the DATA LIST as the first step in troubleshooting is one

method to shorten labor time.

1. DATA LIST FOR OCCUPA ...

EVAP System

RELATED DTCS

If any EVAP system DTCs are set, the malfunctioning area can be determined

using the table below.

NOTICE:

If the 0.02 inch reference pressure difference between the first and

second checks is greater than

the specification, the DTCs corresponding to the refe ...

Smart key system

The following operations can be performed simply by carrying

the electronic key on your person, for example in your pocket.

The driver should always carry the electronic key.

Locks and unlocks the doors

Front door handles

Sliding door handles

Back door

Starts and stops the ...