Toyota Sienna Service Manual: Removal

1. Remove engine under cover no.1 2. Disconnect cable from negative battery terminal 3. Drain automatic transaxle fluid (see page ax-131) 4. Remove automatic transaxle oil pan subassembly

(a) Remove the 18 bolts, oil pan and gasket.

| NOTICE: Some fluid will remain in the oil pan. Carefully remove the oil pan so that the fluid remaining in the pan does not spill out. |

(b) Remove the 2 magnets from the oil pan.

(c) Examine particles in the pan.

(1) Collect any steel chips using the removed magnets. Look carefully at the chips and particles in the pan and on the magnets to see the type of wear which might be found in the transaxle.

Result: Steel (magnetic): Wear of the bearing, gear or plate Brass (non-magnetic): Wear of the bearing

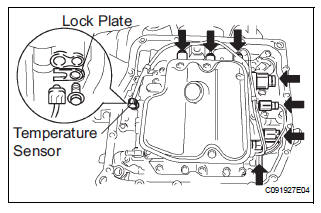

5. DISCONNECT TRANSMISSION WIRE

(a) Disconnect the 7 shift solenoid valve connectors.

(b) Remove the bolt and lock plate, and disconnect the ATF temperature sensor.

6. REMOVE VALVE BODY OIL STRAINER ASSEMBLY

(a) Remove the 3 bolts and oil strainer.

| NOTICE: Be careful when removing the oil strainer as fluid will come out. |

(b) Remove the O-ring from the valve body oil strainer assembly.

7. REMOVE TRANSMISSION VALVE BODY ASSEMBLY

(a) Support the valve body assembly and remove the 17 bolts and the transmission valve body assembly.

(b) Remove the check ball body and the spring.

(c) Remove the bolt and lock plate from the valve body assembly.

(d) Remove the shift solenoid valve SL3 and SLT from the valve body assembly.

(e) Remove the bolt and shift solenoid valve S4 from the valve body assembly

(f) Remove the shift solenoid valve SR from the valve body assembly.

(g) Remove the bolt and shift solenoid valve DSL from the valve body assembly.

(h) Remove the bolt and shift solenoid valve SL2 from the valve body assembly.

(i) Remove the bolt and shift solenoid valve SL1 from the valve body assembly.

Valve body assembly

Valve body assembly

Components

...

Installation

Installation

1. Install transmission valve body assembly

(a) Install the shift solenoid valve SL1 to the valve body

assembly with the bolt.

Torque: 6.6 N*m (67 kgf*cm, 58 in.*lbf)

(b) Install the shi ...

Other materials:

Multiplex Communication Circuit

DESCRIPTION

INSPECTION PROCEDURE

1 GO TO CAN COMMUNICATION SYSTEM

(a) Refer to the CAN communication system (See page CA-

7).

(b) If the CAN communication system is operating normally,

proceed to the next step.

2 GO TO MULTIPLEX COMMUNICATION SYSTEM (BEAN)

(a) Refer to the multiplex com ...

Scratched / Reversed Disc

DTC 44-46 Scratched / Reversed Disc

DESCRIPTION

DTC No.

DTC Detecting Condition

Trouble Area

44-46

Scratches or dirt is found on DVD surface or DVD is set

upside down.

DVD

Television display assembly

INSPECTION PROCEDURE

HI ...

Air Mix Damper Position Sensor Circuit (Passenger Side)

DESCRIPTION

This sensor detects the position of the air mix control servo motor (air mix

damper) and sends the

appropriate signals to the A/C amplifier. The position sensor is built in the

air mix control servo motor. The

position sensor's resistance changes as the air mix control servo m ...