Toyota Sienna Service Manual: Low Battery Positive Voltage

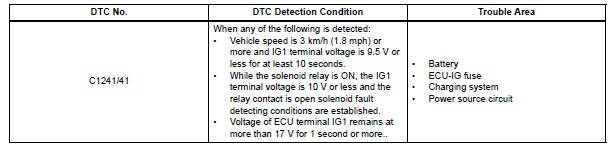

DTC C1241/41 Low Battery Positive Voltage

DESCRIPTION

If there is a problem with the brake actuator assembly (skid control ECU) power supply circuit, the skid control ECU outputs the DTC and prohibits the ABS operation with the fail safe function.

If the voltage supplied to the IG1 terminal is not within the DTC detection threshold due to malfunctions in such as the battery and alternator circuit, this DTC is stored.

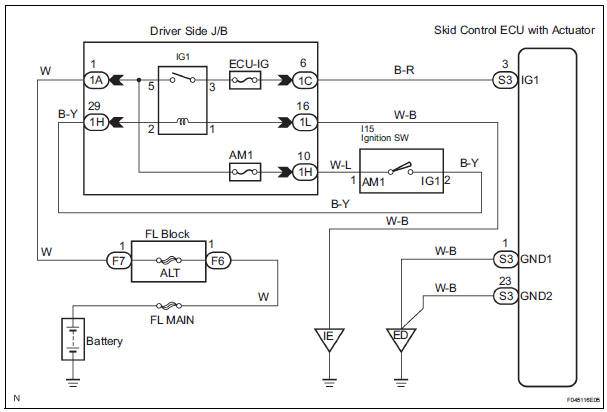

WIRING DIAGRAM

INSPECTION PROCEDURE

HINT: After steps 1 and 2 are completed, start the inspection from step 3 when using the intelligent tester, and from step 4 when not using the intelligent tester.

1 INSPECT BATTERY

(a) Check the battery voltage.

Standard voltage: 11 to 14 V

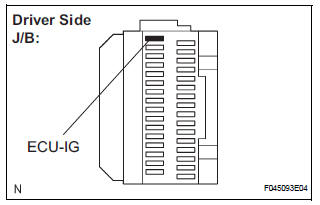

2 INSPECT FUSE (ECU-IG FUSE)

(a) Remove the ECU-IG fuse from the driver side J/B.

(b) Measure the resistance according to the value(s) in the table below.

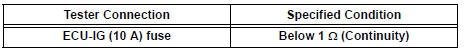

Standard resistance

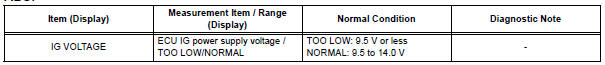

3 READ VALUE OF INTELLIGENT TESTER (IG1 POWER SUPPLY)

(a) Install the ECU-IG fuse.

(b) Connect the intelligent tester to the DLC3.

(c) Turn the ignition switch to the ON position and turn the intelligent tester main switch on.

(d) Start the engine.

(e) Select the DATA LIST mode on the intelligent tester.

ABS:

(f) Measure the voltage output from the ECU displayed on the intelligent tester.

OK: "Normal" is displayed.

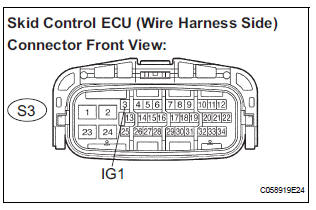

4 INSPECT SKID CONTROL ECU (IG1 TERMINAL VOLTAGE)

(a) Disconnect the skid control ECU connector.

(b) Turn the ignition switch to ON position.

(c) Measure the voltage according to the value(s) in the table below.

Standard voltage

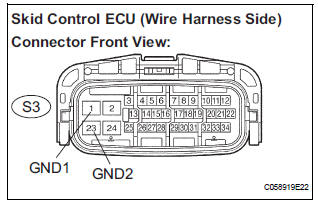

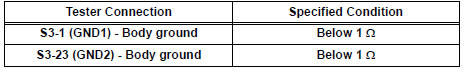

5 INSPECT SKID CONTROL ECU (GND TERMINAL CONTINUITY)

(a) Turn the ignition switch off.

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

6 RECONFIRM DTC

(a) Clear the DTCs (See page BC-10).

(b) Check that the same DTC is recorded (See page BC- 10).

HINT: Reinstall the sensors, connectors, etc. and restore the vehicle to its prior condition before rechecking for DTCs.

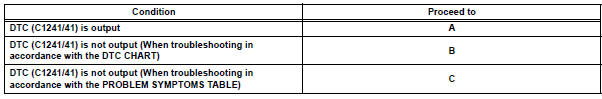

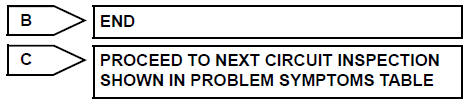

Result

REPLACE BRAKE ACTUATOR ASSEMBLY

Open in ABS Solenoid Relay Circuit

Open in ABS Solenoid Relay Circuit

DESCRIPTION

This relay supplies power to each ABS solenoid.

Immediately after the ignition switch is turned to the ON position, the relay

turns on if the solenoid is

determined to be normal ...

Open in Stop Light Switch Circuit

Open in Stop Light Switch Circuit

DTC C1249/49 Open in Stop Light Switch Circuit

DESCRIPTION

This skid control ECU inputs the stop light switch signal and detects the

status of brake operation.

The skid control ECU has an open ...

Other materials:

Slide door lock

INSPECTION

1. INSPECT SLIDE DOOR LOCK REMOTE CONTROL SUB-ASSEMBLY LH

Inspect the resistance of the switch.

Resistance

If the result is not as specified, replace the control

assembly.

2. INSPECT SLIDE DOOR LOCK REMOTE CONTROL SUB-ASSEMBLY RH

Inspect the resistance of the swit ...

Rear Blower Motor Circuit

DESCRIPTION

Power to the rear blower motor is supplied from the battery via the RR A/C

relay.

The rear blower motor speed level varies between 0 and 31 based on the voltage

difference measured

between the terminals of the motor.

The voltage difference measured between the terminals of th ...

Disassembly

1. REMOVE PROPELLER SHAFT ASSEMBLY

(a) Put matchmarks on both the flanges.

(b) Remove the 4 nuts, bolts and washers.

2. REMOVE INTERMEDIATE SHAFT

(a) Put matchmarks on the propeller shaft subassembly

and universal joint flange.

NOTICE:

Do not use a punch for the marks.

(b) Using a ...