Toyota Sienna Service Manual: Power Back Door does not Operate

DESCRIPTION

- The power back door operates only when the power back door main switch is ON. The power back door ECU controls the power back door by activating the back door motor (built into the power back door drive unit) to open / close the back door.

- A request signal from the satellite switch for power back door is input to the body ECU, which then sends this signal using a BEAN line to the power back door ECU so that the power back door is opened / closed.

- When a request signal is output from the satellite switch while the power back door is operating, the power back door reverses operation.

- If the power back door is manually moved in a specified distance when the back door is in the fully closed / opened position, the power back door will be activated and continue to operate to the fully opened / closed position.

- A request signal from the outside handle switch is directly input to the power back door ECU.

- Pulling the outside handle switch when the back door is in the fully closed position releases the latch of the closer and makes the back door not-fully-closed, which does not activate the power back door to open. (The power back door operation can be switched by customization.)

- When a request signal is output from the outside handle switch while the power back door is operating, the power back door reverses operation.

- When a request signal is output from the outside handle switch when the back door is in the fully open position, the power back door is activated to fully close. (Power back door operation can be changed by customization.)

- When the touch sensor has an open / short-circuit, closing of the power back door is disabled.

NOTICE: When disconnecting the negative (-) terminal cable of the battery or drive unit, initialize the power back door system

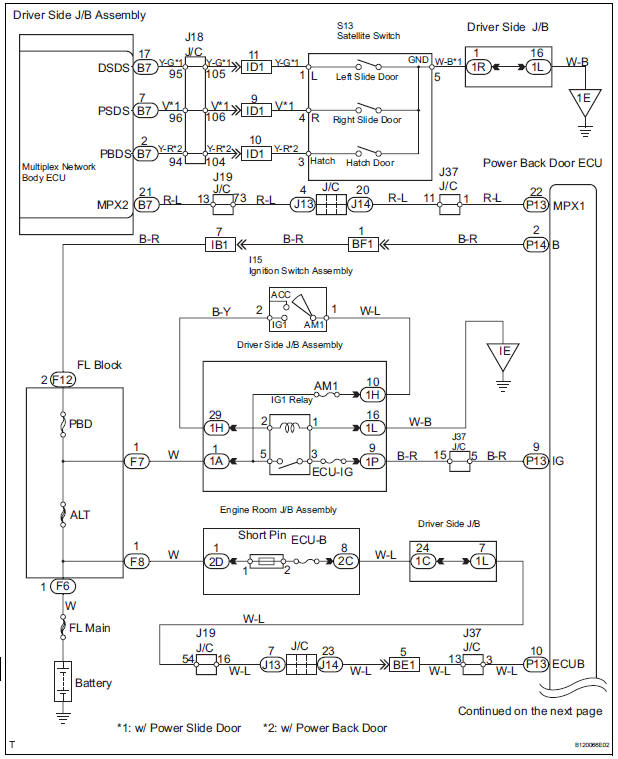

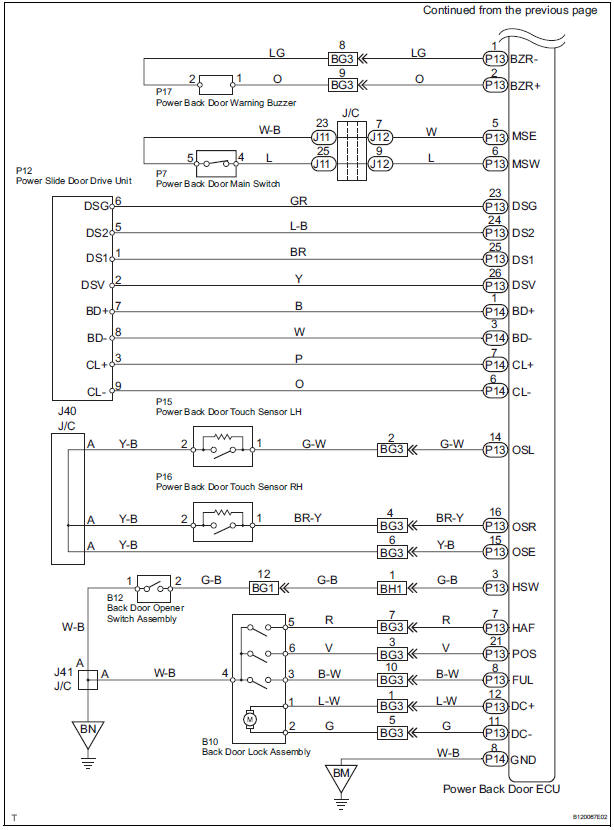

WIRING DIAGRAM

INSPECTION PROCEDURE

1 BASIC INSPECTION

- Conditions necessary for the power back door to open:

- Power back door main switch is in the ON position (switch free: orange paint on the top of the switch appears).

- Back door is between the fully closed position and approximately around the half-open position.

- Shift lever is in the P position when the ignition switch is ON (When the ignition switch is OFF, the power back door operates in any position of the shift lever.)

- Conditions necessary for the power back door to close:

- Power back door main switch is in the ON position (switch free: orange paint on the top of the switch appears).

- Back door is between approximately around the half-open position and the fully open position.

- Back door touch sensor is not damaged and deformed.

2 INSPECT FUSE (ECU-B, ECU IG, AM1)

- Inspect the ECU-B, ECU IG and AM1 fuses.

3 CHECK DTC

- Check for DTC B2222. DTC B2222 indicates a pulse sensor malfunction.

- Without code outputs, proceed to A.

- With code outputs, proceed to B.

4 INSPECT COMMUNICATION FUNCTION OF LARGE-SCALE MULTIPLEX COMMUNICATION SYSTEM (BEAN)

- Use the intelligent tester to check for normal function of the multiplex communication system.

- (ECU unconnected, communication line malfunctioning) Without DTC B1214, B1215 or B1287 outputs, proceed to A.

- (ECU unconnected, communication line malfunctioning) With DTC B1214, B1215 or B1287 outputs, proceed to B.

5 READ VALUE OF INTELLIGENT TESTER

- Using the intelligent tester, check the DATA LIST for proper functioning of the power back door main switch.

OK (Power back door ECU):

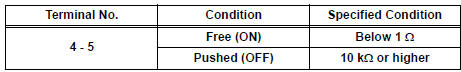

6 INSPECT POWER BACK DOOR MAIN SWITCH

- Inspect the resistance of the main switch.

Resistance

HINT: If the switch does not illuminate, it will not affect the ON / OFF function of the switch. For the illumination check, refer to INSPECTION

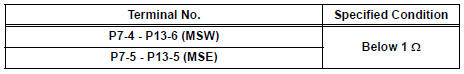

7 CHECK WIRE HARNESS (POWER BACK DOOR MAIN SWITCH - POWER BACK DOOR ECU)

- Disconnect the P7 main switch and P13 ECU connectors.

- Check the resistance between the wire harness side connectors.

Resistance (Check for open circuit)

REPLACE POWER BACK DOOR ECU

8 CHECK SWITCH OPERATION

- If the power back door does not respond to using the satellite switch, proceed to A.

- If the power back door does not respond to using the back door opener switch outside, proceed to B.

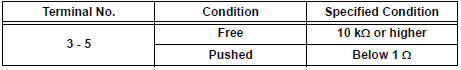

9 INSPECT SATELLITE SWITCH

- Inspect the resistance of the back door switch.

Resistance

HINT: If the switch does not illuminate, it will not affect the ON / OFF function of the switch. For the illumination check, refer to INSPECTION

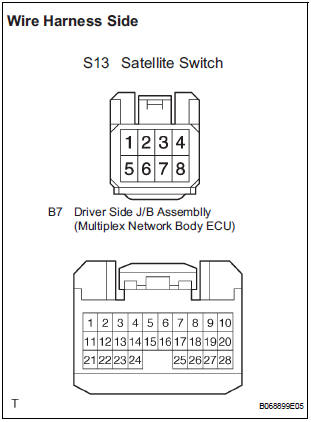

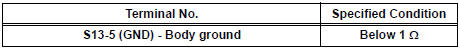

10 CHECK WIRE HARNESS (SATELLITE SWITCH - DRIVER SIDE J/B, BODY GROUND)

- Disconnect the S13 switch and the B7 ECU connectors.

- Check the resistance between the wire harness side connectors.

Resistance (Check for open circuit)

- Check the resistance between the S13 switch connector and body ground.

Resistance (Check for open circuit)

REPAIR OR REPLACE HARNESS AND CONNECTOR

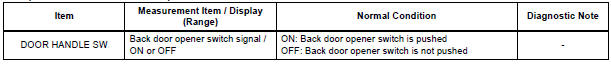

11 READ VALUE OF INTELLIGENT TESTER

- Using the intelligent tester, check the DATA LIST for proper functioning of the back door opener switch (Outside handle switch).

OK (Power back door ECU):

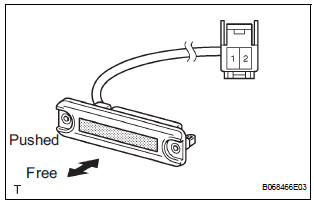

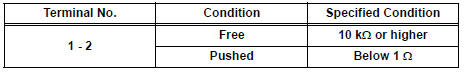

12 INSPECT BACK DOOR OPENER SWITCH ASSEMBLY (OUTSIDE HANDLE SWITCH)

- Inspect the resistance of the switch.

Resistance

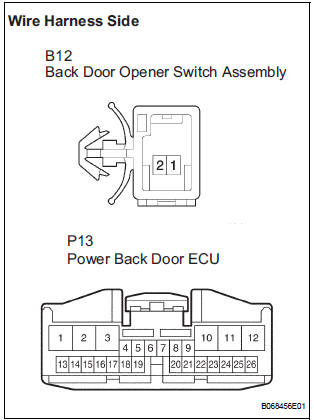

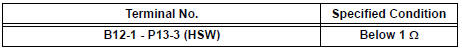

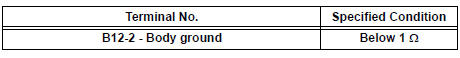

13 CHECK WIRE HARNESS (BACK DOOR OPENER SWITCH - POWER BACK DOOR ECU AND GROUND)

- Disconnect the B12 switch and P13 ECU connectors.

- Check the resistance between the wire harness side connectors.

Resistance (Check for open circuit)

- Check the resistance between the B12 switch connector and body ground.

Resistance (Check for open circuit)

REPLACE POWER BACK DOOR ECU

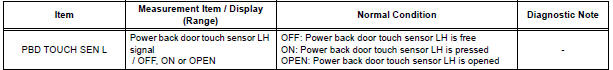

14 READ VALUE OF INTELLIGENT TESTER

- Using the intelligent tester, check the DATA LIST for proper functioning of the power back door touch sensor LH.

OK (Power back door ECU):

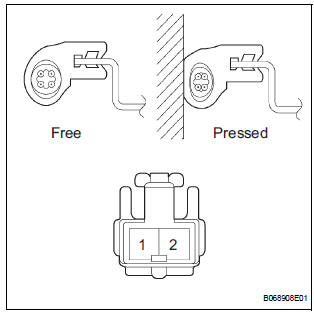

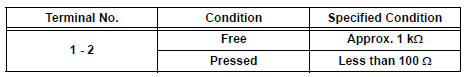

15 INSPECT POWER BACK DOOR TOUCH SENSOR LH

- Check the resistance of the sensor.

Resistance

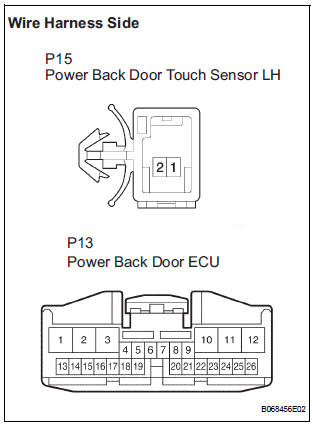

16 CHECK WIRE HARNESS (POWER BACK DOOR TOUCH SENSOR LH - POWER BACK DOOR ECU)

- Disconnect the P15 sensor and P13 ECU connectors.

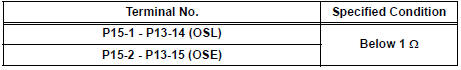

- Check the resistance between the wire harness side connectors.

Resistance (Check for open circuit)

REPLACE POWER BACK DOOR ECU

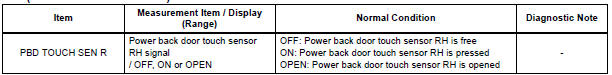

17 READ VALUE OF INTELLIGENT TESTER

- Using the intelligent tester, check the DATA LIST for proper functioning of the power back door touch sensor RH.

OK (Power back door ECU):

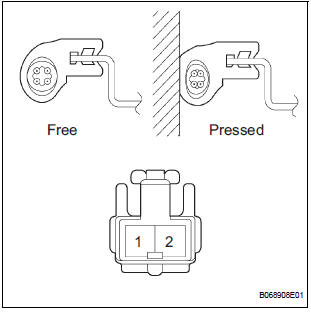

18 INSPECT POWER SLIDE DOOR WARNING BUZZER

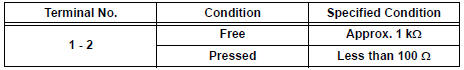

- Check the resistance of the sensor.

Resistance

19 CHECK WIRE HARNESS (POWER BACK DOOR TOUCH SENSOR RH - POWER BACK DOOR ECU)

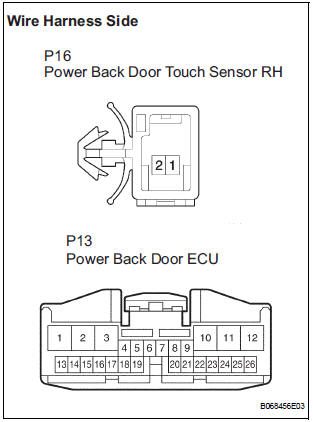

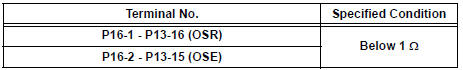

- Disconnect the P16 sensor and P13 ECU connectors.

- Check the resistance between the wire harness side connectors.

Resistance (Check for open circuit)

REPLACE POWER BACK DOOR ECU

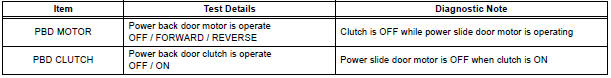

20 PERFORM ACTIVE TEST BY INTELLIGENT TESTER

- Select the ACTIVE TEST and then check that the power back door drive unit operates.

HINT: During the ACTIVE TEST, the intelligent tester sends a signal to the power back door ECU to drive the power back door drive unit. If the power back door drive unit operates, the power back door drive unit itself and the wire harness between the power back door drive unit and power back door ECU are considered to be functionary normally

OK (Power back door ECU):

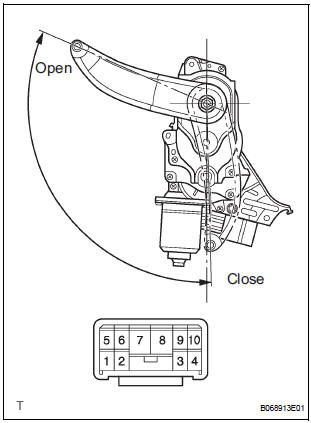

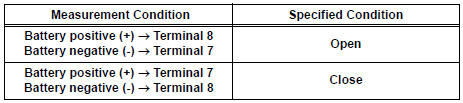

21 INSPECT POWER BACK DOOR DRIVE UNIT

- Remove the unit.

- Connect the battery positive (+) lead to terminal 3 and battery negative (-) terminal lead to terminal 9.

- Apply battery voltage to the terminals and check the motor operation.

OK

- Check the resistance of the clutch terminals.

Resistance

- Reinstall the unit with the connector connected.

- Check the pulse of the pulse sensor.

- Using an oscilloscope, check the pulse generated when the door is manually opened and closed.

Reference

HINT: A cycle of the pulse changes between approx. 10 to 20 msec. according to the speeds that the slide door is moving.

NOTICE: When disconnecting the drive unit, initialize the power back door system

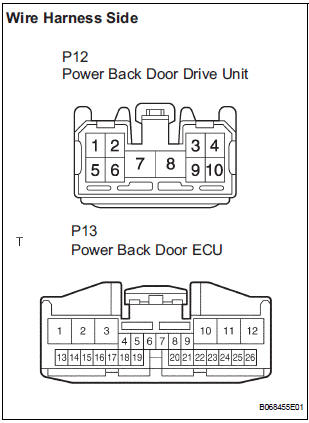

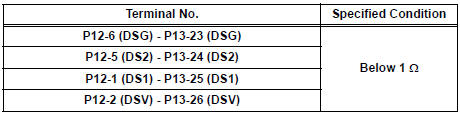

22 CHECK WIRE HARNESS (POWER BACK DOOR DRIVE UNIT - POWER BACK DOOR ECU)

- Disconnect the P12 unit and P13 ECU connectors.

- Check the resistance between the wire harness side connectors.

Resistance (Check for open circuit)

REPLACE POWER BACK DOOR ECU

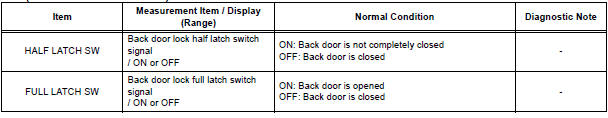

23 READ VALUE OF INTELLIGENT TESTER

- Using the intelligent tester, check the DATA LIST for proper functioning of the switches listed below.

OK (Power back door ECU):

24 INSPECT BACK DOOR LOCK ASSEMBLY

25 CHECK WIRE HARNESS (BACK DOOR LOCK ASSEMBLY - POWER BACK DOOR ECU)

26 REPLACE POWER BACK DOOR ECU

- Check the power back door for normal OPEN / CLOSE operation

SYSTEM NORMAL

PBD Pulse Sensor Malfunction

PBD Pulse Sensor Malfunction

DTC B2222 PBD Pulse Sensor Malfunction

DESCRIPTION

A pulse sensor is built into the back door for a jam and foreign

object detection and for back door

position detection. The jam and foreign ...

Jam Protection Function Activates During Power Back Door Operation

Jam Protection Function Activates During Power Back Door Operation

DESCRIPTION

It may be caused by ill-fitting back door, faulty touch sensor or

faulty pulse sensor.

The power back door ECU activates the back motor to open / close

the power back door, thu ...

Other materials:

Installation

1. INSTALL SPIRAL CABLE

Check that the front wheels are facing straight

ahead.

Set the turn signal switch to the neutral position.

NOTICE:

If it is not in the neutral position, the pin of the

turn signal switch may snap.

Install the spiral cable.

NOTICE:

...

Diagnostic trouble code chart

Look for output Diagnostic Trouble Codes (DTCs) (from the

DTC checks) in the appropriate section's Diagnostic Trouble

Code Chart. Use the chart to determine the trouble area and

the proper inspection procedure. A description of each of the

chart's columns is shown in the table below.

Ite ...

Terminals of ecu

1. Terminal of ECU

(*1): Models with dynamic laser cruise control

(*2): 2WD model

2. Terminal Inspection

(a) Disconnect the connector and measure the voltage

or resistance on the wire harness side.

HINT:

Voltage cannot be measured with the connector

connected to the skid control ECU ...