Toyota Sienna Service Manual: Pressure Control Solenoid "A" Electrical (Shift Solenoid Valve SL1)

DESCRIPTION

Shifting from 1st to 5th is performed in combination with "ON" and "OFF"

operation of the shift solenoid

valves SL1, SL2, SL3, S4 and SR which are controlled by the ECM. If an open or

short circuit occurs in

either of the shift solenoid valves, the ECM controls the remaining normal shift

solenoid valves to allow

the vehicle to be operated smoothly (Fail safe function).

MONITOR DESCRIPTION

The ECM commands gear shifts by turning the shift solenoid valves "ON/OFF". When there is an open or short circuit in any shift solenoid valve circuit, the ECM detects the problem and illuminates the MIL and stores the DTC. And the ECM performs the fail-safe function and turns the other normal shift solenoid valves "ON/OFF" (In case of an open or short circuit, the ECM stops sending current to the circuit.) (See page AX-30).

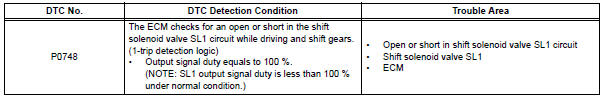

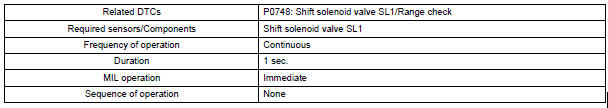

MONITOR STRATEGY

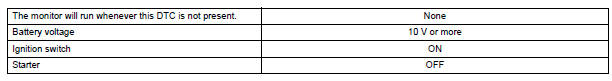

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

COMPONENT OPERATING RANGE

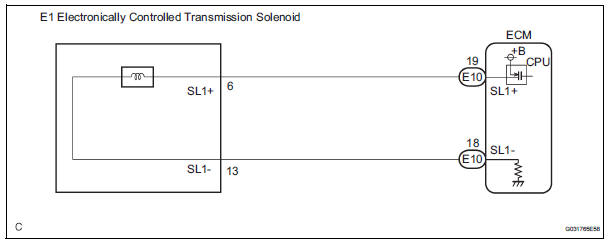

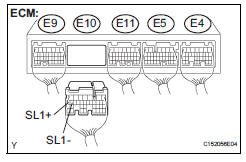

WIRING DIAGRAM

INSPECTION PROCEDURE

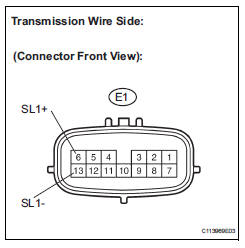

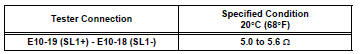

1 INSPECT TRANSMISSION WIRE (SL1)

(a) Disconnect the transmission wire connector from the transaxle.

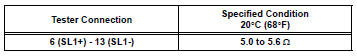

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

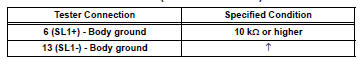

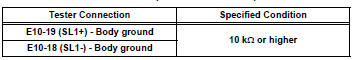

(c) Measure the resistance according to the value(s) in the table below.

Standard resistance (Check for short)

2 CHECK HARNESS AND CONNECTOR (TRANSMISSION WIRE - ECM)

(a) Connect the transmission wire connector to the transaxle.

(b) Disconnect the connector from the ECM.

(c) Measure the resistance according to the value(s) in the table below.

Standard resistance

(d) Measure the resistance according to the value(s) in the table below.

Standard resistance (Check for short)

REPLACE ECM

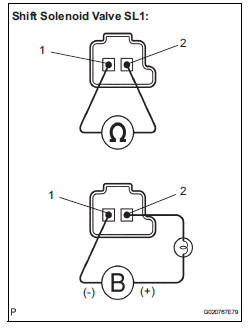

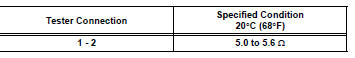

INSPECT SHIFT SOLENOID VALVE SL1

(a) Remove the shift solenoid valve SL1.

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

(c) Connect the positive (+) lead with a 21 W bulb to terminal 2 and the negative (-) lead to terminal 1 of the solenoid valve connector, then check the movement of the valve.

OK: The solenoid makes an operating sound.

REPAIR OR REPLACE TRANSMISSION WIRE

Pressure Control Solenoid "A" Performance (Shift Solenoid

Valve SL1)

Pressure Control Solenoid "A" Performance (Shift Solenoid

Valve SL1)

SYSTEM DESCRIPTION

The ECM uses signals from the vehicle speed sensor to

detect the actual gear position (1st, 2nd, 3rd, 4th

or 5th gear).

Then the ECM compares the actual gear with the shi ...

Shift Solenoid "D" Performance (Shift Solenoid

Valve S4)

Shift Solenoid "D" Performance (Shift Solenoid

Valve S4)

SYSTEM DESCRIPTION

The ECM uses signals from the vehicle speed sensor to detect the actual gear

position (1st, 2nd, 3rd, 4th

or 5th gear).

Then the ECM compares the actual gear with the shi ...

Other materials:

Disassembly

1. REMOVE REAR DOOR WINDOW FRAME MOULDING

REAR LH (See page ET-31)

2. REMOVE REAR DOOR WINDOW FRAME MOULDING

SUB-ASSEMBLY LH (See page ET-32)

3. REMOVE SLIDE DOOR WINDOW GARNISH LH

Fully open the slide door window.

Remove the glass run.

Using a screwdriver, disengage the clip and rem ...

Master Reset/ Voice Processing Device ON Error

DTC 01-DD Master Reset

DTC 01-E1 Voice Processing Device ON

DESCRIPTION

DTC No.

DTC Detection Condition

Trouble Area

01-DD

*1

The device that should be the master has been

disconnected after the engine starts.

Radio and navigation assembly po ...

On-vehicle cleaning

1. INSPECT RADIATOR ASSEMBLY

(a) Check that the radiator and condenser are not

blocked with leaves, dirt, or insects. Clean the hose

connections.

If the fins are blocked, wash them with water or a

steam cleaner.

NOTICE:

If the distance between the steam cleaner and

core is ...