Toyota Sienna Service Manual: Rear Blower Motor Circuit

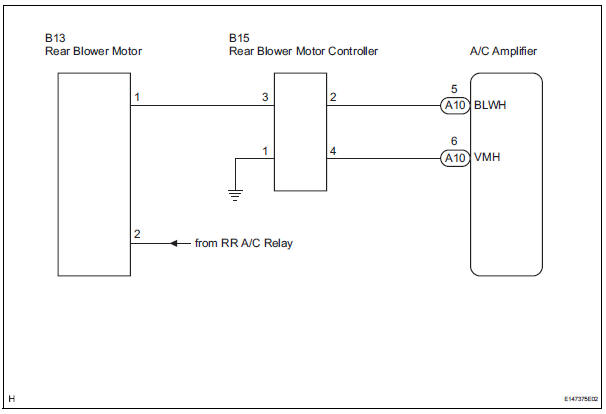

DESCRIPTION

Power to the rear blower motor is supplied from the battery via the RR A/C relay.

The rear blower motor speed level varies between 0 and 31 based on the voltage difference measured between the terminals of the motor.

The voltage difference measured between the terminals of the rear blower motor changes in proportion to the control at the rear blower motor controller on the ground side.

WIRING DIAGRAM

INSPECTION PROCEDURE

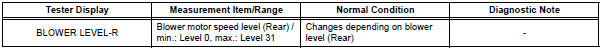

1 READ VALUE OF INTELLIGENT TESTER

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the intelligent tester main switch on.

(c) Select the item below in the DATA LIST, and read the display on the intelligent tester.

DATA LIST / AIR CONDITIONER

OK: The display is as specified in the normal condition.

PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS TABLE

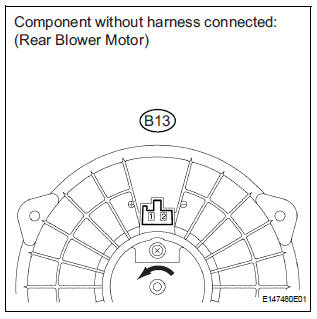

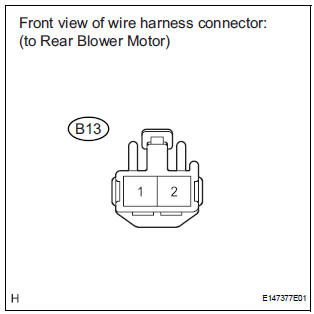

2 INSPECT REAR BLOWER MOTOR

(a) Remove the rear blower motor with the connector still connected.

(b) Disconnect the connector from the rear blower motor.

(c) Connect the positive (+) lead to terminal 1 of the rear blower motor connector, and the negative (-) lead to terminal 2.

OK: The rear blower motor operates smoothly.

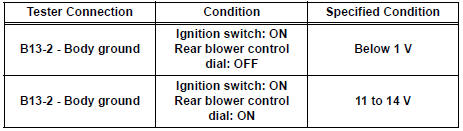

3 CHECK HARNESS AND CONNECTOR (REAR BLOWER MOTOR - BATTERY)

(a) Measure the voltage according to the value(s) in the table below.

Standard voltage

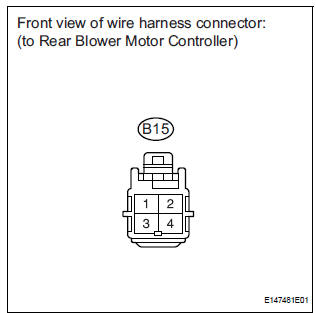

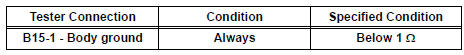

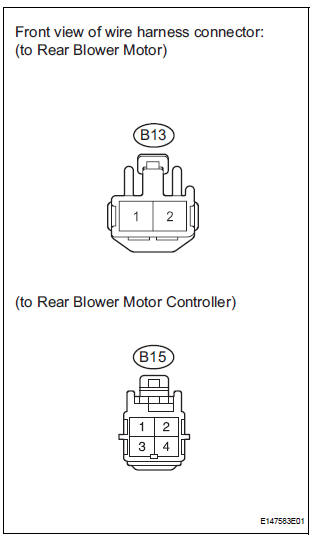

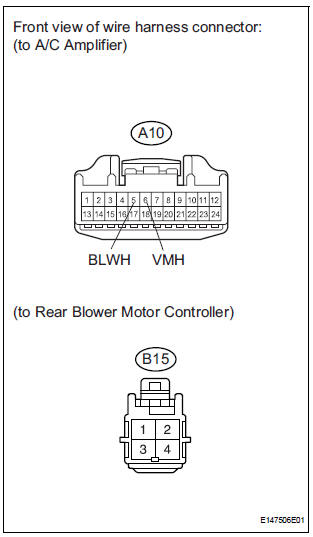

4 CHECK HARNESS AND CONNECTOR (REAR BLOWER MOTOR CONTROLLER - BODY GROUND)

(a) Disconnect the connector from the rear blower motor controller.

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

5 CHECK HARNESS AND CONNECTOR (REAR BLOWER MOTOR - REAR BLOWER MOTOR CONTROLLER)

(a) Measure the resistance according to the value(s) in the table below.

Standard resistance

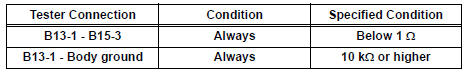

6 CHECK HARNESS AND CONNECTOR (REAR BLOWER MOTOR CONTROLLER - A/C AMPLIFIER)

(a) Disconnect the connector from the A/C amplifier.

(b) Measure the resistance according to the value(s) in the table below.

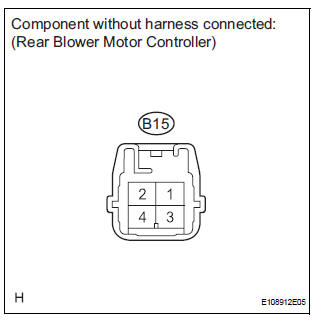

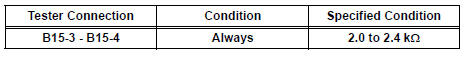

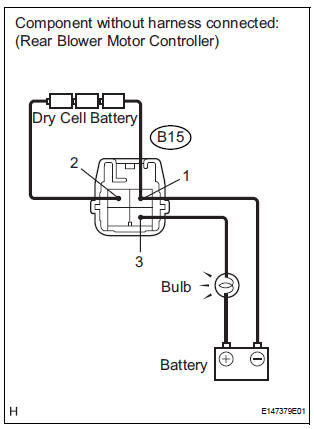

7 INSPECT REAR BLOWER MOTOR CONTROLLER

(a) Disconnect the connector from the rear blower motor controller.

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

(c) Connect the positive (+) lead to terminal 3 through a 12 V 3.4 W test bulb, and the negative (-) lead to terminal 1.

(d) Connect the three 1.5 V dry cell batteries' positive (+) lead to terminal 2, and the negative (-) lead to terminal 1.

Then check that the test bulb comes on.

OK: The test bulb comes on.

PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS TABLE

Rear Air Conditioning Relay Circuit

Rear Air Conditioning Relay Circuit

DESCRIPTION

The RR A/C relay is switched on by signals from the A/C amplifier. It

supplies power to the rear blower

motor.

WIRING DIAGRAM

INSPECTION PROCEDURE

1 INSPECT RELAY (RR A/C)

...

IG Power Source Circuit

IG Power Source Circuit

DESCRIPTION

The main power source is supplied to the A/C amplifier when the ignition

switch is turned to the ON

position.

The power source is used for operating the A/C amplifier and servo moto ...

Other materials:

Intermediate Shaft Speed Sensor "A"

DESCRIPTION

This sensor detects the rotation speed of the counter gear. By comparing the

counter gear speed signal

(NC) with the direct clutch speed sensor signal (NT), the ECM detects the shift

timing of the gears and

appropriately controls the engine torque and hydraulic pressure according ...

Operation check

1. DETECTION RANGE MEASUREMENT AND INDICATOR CHECK

Turn the IG switch ON.

Move the shift lever to the R position (when the back

sonar and rear clearance sonar is checked).

With front clearance sonar:

Move the shift lever to the N position (when the front

clearance son ...

If the vehicle becomes

stuck

Carry out the following procedures if the tires spin or the vehicle

becomes stuck in mud, dirt, or snow:

Stop the engine. Set the parking brake and shift the shift lever to P.

Remove the mud, snow, or sand from around the stuck tire.

Place wood, stones or some other material under the tires ...