Toyota Sienna Service Manual: Reassembly

1. INSTALL IGNITION OR STARTER SWITCH ASSEMBLY

(a) Install the ignition or starter switch assembly to the steering column bracket assembly UPR with the 2 screws.

2. INSTALL KEY INTER LOCK SOLENOID

(a) Install the solenoid to the steering column bracket assembly with the 2 screws.

3. INSTALL UN-LOCK WARNING SWITCH ASSEMBLY

(a) Install the un-lock warning switch assembly.

(b) Connect terminals 1 and 2 of the un-lock warning switch assembly connector.

(c) Connect the un-lock warning switch assembly connector to the ignition or starter switch assembly.

4. INSTALL IGNITION SWITCH LOCK CYLINDER ASSEMBLY

(a) Make sure that the ignition switch lock cylinder assembly is in the ACC position.

(b) Install the ignition switch lock cylinder assembly.

5. INSTALL STEERING LOCK OPERATION

(a) Check that the steering lock mechanism is activated when removing the key.

(b) Check that the steering lock mechanism is deactivated when inserting the key and turning it to the ACC position

6. INSTALL STEERING COLUMN BRACKET ASSEMBLY UPPER

(a) Temporarily install the steering column upper w/ switch bracket assembly and steering column upper clamp with 2 new tapered-head bolts.

(b) Tighten the 2 tapered-head bolts until the bolt heads break off.

7. INSTALL KEY CYLINDER LIGHT ASSEMBLY (w/o Engine Immobiliser System)

8. INSTALL TRANSPONDER KEY AMPLIFIER (w/ Engine Immobiliser System)

(a) Align the transponder key amplifier with the installation position of the upper bracket with the amplifier inclined.

(b) Push the transponder key amplifier up and connect it to the upper bracket.

NOTICE: Take care not to push the amplifier up with excessive force to prevent it from being damaged.

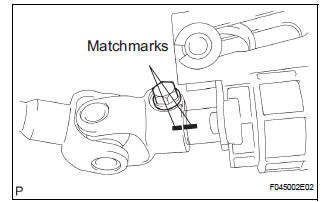

9. INSTALL STEERING INTERMEDIATE SHAFT ASSEMBLY

(a) Align the matchmarks on the steering intermediate shaft assembly and main shaft.

(b) Temporarily install the steering intermediate shaft assembly with the bolt.

Torque: 36 N*m (370 kgf*cm, 27 ft.*lbf)

Disassembly

Disassembly

1. REMOVE STEERING INTERMEDIATE SHAFT ASSEMBLY

(a) Align the matchmarks on the steering intermediate

shaft assembly and main shaft.

(b) Remove the bolt and steering intermediate shaft

assemb ...

Installation

Installation

1. INSTALL STEERING COLUMN ASSEMBLY

(a) Install the steering column assembly with the 3

bolts.

Torque: 25 N*m (255 kgf*cm, 18 ft.*lbf)

(b) Connect the connectors.

(c) Connect the wire har ...

Other materials:

Dtc check / clear

1. DTC CHECK (NORMAL MODE)

NOTICE:

When the diagnostic system is switched from the

normal mode to the check mode, all the DTCs and

freeze frame data recorded in the normal mode will

be erased. So before switching modes, always check

the DTCs and freeze frame data, and note the ...

Removal

NOTICE:

When installing, coat the parts indicated by the arrows

with power steering fluid or molybdenum disulfide

lithium base grease (See page PS-21).

1. INSPECT CENTER FRONT WHEEL

2. REMOVE FRONT WHEEL

3. SEPARATE TIE ROD ASSEMBLY LH

SST 09628-62011

4. SEPARATE TIE ROD ASSEMBLY RH

SST 096 ...

ABS Warning Light Remains ON

DESCRIPTION

If any of the following is detected, the ABS warning light remains on.

The skid control ECU connectors are disconnected from the skid control

ECU.

There is a malfunction in the skid control ECU internal circuit.

There is an open in the harness between the combination meter an ...