Toyota Sienna Service Manual: Removal

1. Remove v-bank cover sub-assembly (see page em-28) 2. Remove front wheel rh 3. Remove no. 1 Engine under cover (see page em-26) 4. Remove front fender apron seal rh (see page em-26) 5. Drain engine coolant (see page co-6) 6. Remove no. 2 Air cleaner inlet (see page em- 28) 7. Remove battery (see page em-26) 8. Remove front bumper assembly (see page et-3) 9. Remove front bumper energy absorber 10. Remove no. 1 Air cleaner inlet (see page em- 28) 11. Disconnect radiator reserve tank hose or pipe (see page co-28) 12. Disconnect no. 1 Radiator hose (see page co- 28) 13. Disconnect no. 2 Radiator hose (see page co- 29) 14. Remove hood lock release lever protector (see page co-29) 15. Remove hood lock assembly (see page co-29) 16. Remove hood lock support sub-assembly (see page co-29) 17. Disconnect cooling fan ecu connector (see page co-30) 18. Remove radiator upper support subassembly (see page co-30) 19. Disconnect no. 2 Oil cooler outlet tube sub-assembly (see page co-31) 20. Remove headlight assembly rh (see page li- 69)

21. Remove radiator side deflector rh (see page co-31) 22. Remove headlight bracket rh (see page co- 32) 23. Remove pressure feed tube assembly (see page co-32)

24. REMOVE RADIATOR SUPPORT CUSHION (See page CO-32) 25. REMOVE NO. 1 RADIATOR SUPPORT (See page CO- 32) 26. REMOVE RADIATOR ASSEMBLY WITH FAN SHROUD AND FAN MOTOR (See page CO-33) 27. REMOVE V-RIBBED BELT (See page EM-6) 28. REMOVE GENERATOR ASSEMBLY

(a) Remove the terminal cap.

(b) Remove the nut and disconnect the wire harness from terminal B.

(c) Disconnect the generator connector from the generator assembly.

(d) Disconnect the connector from the compressor and magnetic clutch.

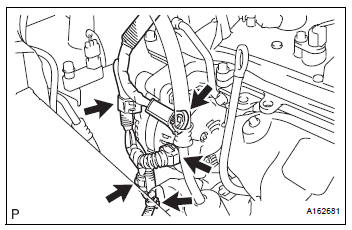

(e) Disconnect the 2 wire harness clamps.

(f) Remove the 2 bolts.

(g) Remove the bolt from the cylinder block.

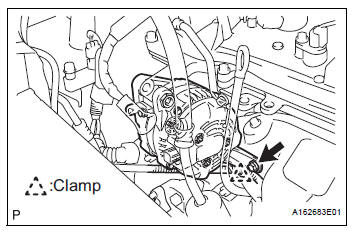

(h) Disconnect the wire harness clamp and remove the generator assembly.

(i) Remove the bolt and wire harness clamp stay.

(j) Remove the bolt and bracket.

Components

Components

...

Disassembly

Disassembly

1. REMOVE GENERATOR CLUTCH PULLEY

(A) using a screwdriver, remove the generator pulley

cap.

(b) Set SST (A) and (B).

SST 09820-63020

(c) Clamp SST (A) in a vise.

NOTICE:

...

Other materials:

Installation

1. INSTALL OCCUPANT CLASSIFICATION ECU

Check that the ignition switch is off.

Check that the negative battery (-) terminal is

disconnected.

CAUTION:

After disconnecting the negative battery

terminal, wait for at least 90 seconds before

starting the operation.

...

Removal

HINT:

Use the same procedures for the RH side and LH side.

The procedures listed below are for the LH side.

1. PRECAUTION

CAUTION: Be sure to read "PRECAUTION" thoroughly before

servicing.

2. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

NOTICE:

Wait for 90 seconds ...

How to proceed with

troubleshooting

HINT:

Use these procedures to troubleshoot the key reminder

warning system.

The intelligent tester should be used in steps 3 and 5.

1 VEHICLE BROUGHT TO WORKSHOP

2 CUSTOMER PROBLEM ANALYSIS

3 INSPECT COMMUNICATION FUNCTION OF MULTIPLEX COMMUNICATION SYSTEM

(BEAN)

Use th ...