Toyota Sienna Service Manual: Removal

1. Disconnect battery negative terminal

2. Remove instrument cluster finish panel sub-assembly center

Hint: (see page ip-9)

3. Remove transmission control cable assembly

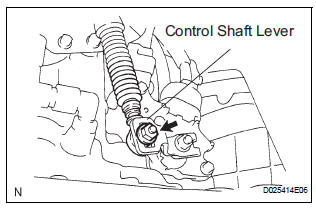

(a) Remove the nut from the control shaft lever.

(b) Disconnect the transmission control cable assembly from the control shaft lever.

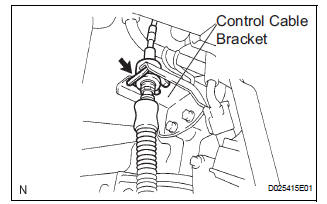

(c) Remove the clip and disconnect the transmission control cable assembly from the control cable bracket

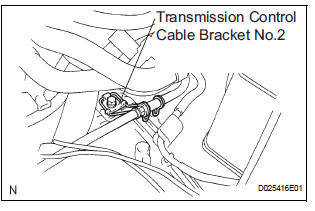

(d) Disconnect the transmission control cable assembly from the transmission control cable bracket No.2.

(e) Remove the 2 nuts and disconnect the transmission control cable assembly from the vehicle.

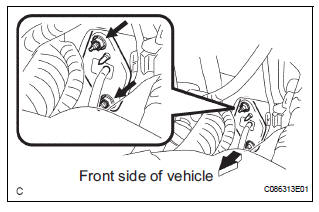

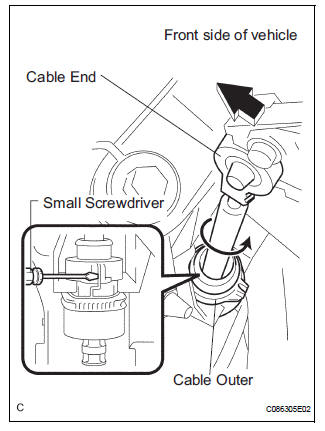

(f) Using a screwdriver, disconnect the cable end from the shift lever assembly (g) Using a small screwdriver, disconnect the cable outer of transmission control cable assembly from the shift lever assembly.

(h) Pull out the control cable from the vehicle.

Transmission control cable assembly

Transmission control cable assembly

COMPONENTS

...

Adjustment

Adjustment

1. INSPECT SHIFT LEVER POSITION

(a) When shifting from P to R position only with ignition

switch ON and brake pedal, make sure that the

shifting lever moves smoothly and can be

moderately operated ...

Other materials:

Open in Driver Side Squib 2nd Step Circuit

DTC B1181/18 Open in Driver Side Squib 2nd Step Circuit

DESCRIPTION

The driver side squib 2nd step circuit consists of the center airbag sensor

assembly, the spiral cable and

the steering pad.

The circuit instructs the SRS to deploy when deployment conditions are met.

DTC B1181/18 is reco ...

Removal

1. PRECAUTION

CAUTION:

Be sure to read "PRECAUTION" thoroughly before

servicing.

2. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

CAUTION:

Wait for 90 seconds after disconnecting the cable to

prevent the airbag working.

3. REMOVE STEERING WHEEL NO.3 COVER LOWER

Using a ...

Short to B+ in Rear Curtain Shield Squib RH

Circuit

DTC B1633/82 Short to B+ in Rear Curtain Shield Squib RH

Circuit

DESCRIPTION

The rear curtain shield squib RH circuit consists of the center airbag sensor

assembly and the curtain

shield airbag assembly RH.

The circuit instructs the SRS to deploy when deployment conditions are met.

DTC B ...