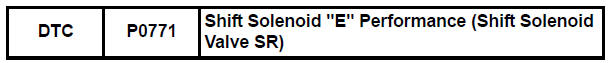

Toyota Sienna Service Manual: Shift Solenoid "E" Performance (Shift Solenoid Valve SR)

SYSTEM DESCRIPTION

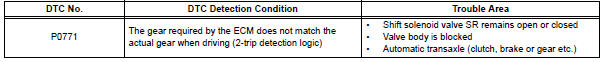

The ECM uses signals from the vehicle speed sensor to detect the actual gear position (1st, 2nd, 3rd, 4th or 5th gear).

Then the ECM compares the actual gear with the shift schedule in the ECM memory

to detect mechanical

problems of the shift solenoid valves, valve body or automatic transaxle

(clutch, brake or gear etc.).

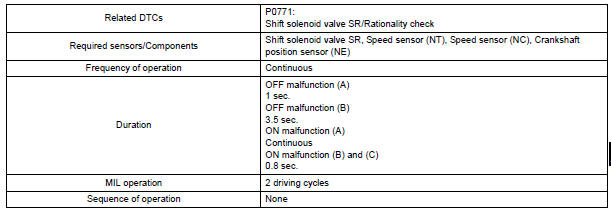

MONITOR DESCRIPTION

The ECM commands gear shifts by turning the shift solenoid valves "ON/OFF". According to the input shaft revolution, intermediate (counter) shaft revolution and output shaft revolution, the ECM detects the actual gear position (1st, 2nd, 3rd, 4th or 5th gear position). When the gear position commanded by the ECM and the actual gear position are not the same, the ECM illuminates the MIL and stores the DTC.

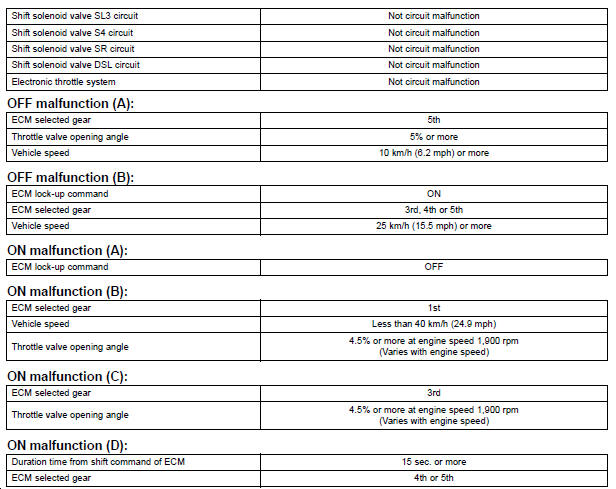

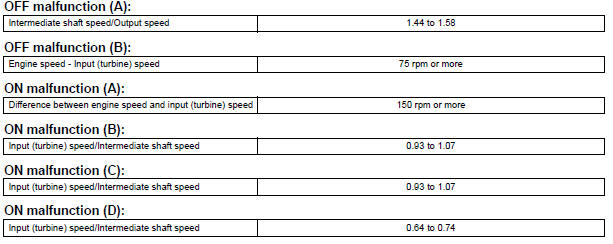

MONITOR STRATEGY

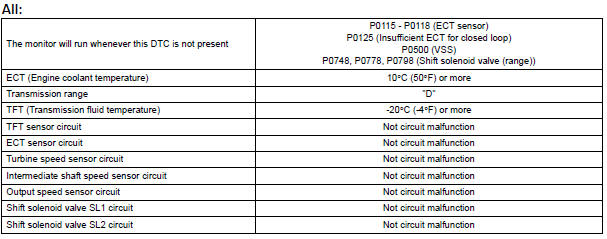

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

Either of the following conditions is met: OFF malfunction (A) and (B), or ON malfunction (A), (B), (C) and (D)

INSPECTION PROCEDURE

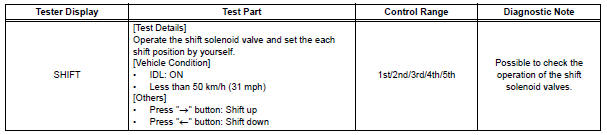

HINT: Using the intelligent tester to perform ACTIVE TEST allows relays, VSVs, actuators and other items to be operated without removing any parts. This non-intrusive functional inspection can be very useful because intermittent operation may be discovered before parts or wiring is disturbed. Performing ACTIVE TEST early in troubleshooting is one way to save diagnostic time. DATA LIST information can be displayed while performing ACTIVE TEST.

1. PERFORM ACTIVE TEST

(a) Warm up the engine.

(b) Turn the ignition switch off.

(c) Connect the intelligent tester together with the CAN VIM (controller area network vehicle interface module) to the DLC3.

(d) Turn the ignition switch to the ON position.

(e) Turn on the tester.

(f) Select the item "DIAGNOSIS / ENHANCED OBD II / ACTIVE TEST / SHIFT".

(g) According to the display on the tester, perform the "ACTIVE TEST".

HINT: While driving, the shift position can be forcibly changed with the intelligent tester.

Comparing the shift position commanded by the ACTIVE TEST with the actual shift

position enables you

to confirm the problem (See page AX-30).

HINT:

- This test can be conducted when the vehicle speed is 50 km/h (31 mph) or less.

- The shift position commanded by the ECM is shown in the DATA LIST/SHIFT display on the intelligent tester.

1 CHECK OTHER DTCS OUTPUT (IN ADDITION TO DTC P0771)

(a) Connect the intelligent tester together with the CAN VIM (controller area network vehicle interface module) to the DLC3.

(b) Turn the ignition switch to the ON position and turn the OBD II scan tool or the intelligent tester main switch ON.

(c) When you use intelligent tester: Select the item "DIAGNOSIS / ENHANCED OBD II / DTC INFO / CURRENT CODES".

(d) Read the DTCs using the OBD II scan tool or the intelligent tester.

Result

HINT: If any other codes besides "P0771" are output, perform the troubleshooting for those DTCs first.

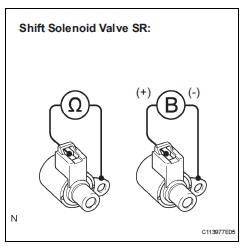

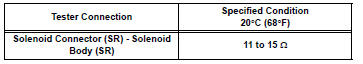

2 INSPECT SHIFT SOLENOID VALVE SR

(a) Remove the shift solenoid valve SR.

(b) Measure the resistance according to the value(s) in the table below.

Standard resistance

(c) Connect positive (+) lead to the terminal of solenoid connector, negative (-) lead to the solenoid body.

OK: The solenoid makes an operating sound.

3 INSPECT TRANSMISSION VALVE BODY ASSEMBLY

OK: There are no foreign objects on each valve and they operate smoothly.

4 INSPECT TORQUE CONVERTER CLUTCH ASSEMBLY

OK: The torque converter clutch operates normally.

REPAIR OR REPLACE AUTOMATIC TRANSAXLE ASSEMBLY

Shift Solenoid "D" Performance (Shift Solenoid

Valve S4)

Shift Solenoid "D" Performance (Shift Solenoid

Valve S4)

SYSTEM DESCRIPTION

The ECM uses signals from the vehicle speed sensor to detect the actual gear

position (1st, 2nd, 3rd, 4th

or 5th gear).

Then the ECM compares the actual gear with the shi ...

Pressure Control Solenoid "B" Performance (Shift

Solenoid Valve SL2)

Pressure Control Solenoid "B" Performance (Shift

Solenoid Valve SL2)

SYSTEM DESCRIPTION

The ECM uses signals from the vehicle speed sensor to detect the actual gear

position (1st, 2nd, 3rd, 4th

or 5th gear).

Then the ECM compares the actual gear with the shi ...

Other materials:

Inspection

1. INSPECT BRAKE DRUM INSIDE DIAMETER

(a) Using a brake drum gauge or equivalent, measure

the inside diameter of the drum.

Standard inside diameter:

254.0 mm (10.00 in.)

Maximum inside diameter:

256.0 mm (10.08 in.)

2. INSPECT REAR DRUM BRAKE SHOE LINING THICKNESS

(a) Using a ruler, ...

Manual headlight leveling dial (vehicles with discharge headlights)

The level of the headlight aim can be adjusted according to the number

of passengers and the loading condition of the vehicle.

Raises the level of the headlights

Lowers the level of the headlights

Guide to dial settings

Daytime running light system (if equipped)

Bulb type: To ...

Disassembly

1. REMOVE RH SEAT REAR SEAT RECLINING COVER

Remove the 2 screws.

Remove the RH seat rear seat reclining cover by

pulling it out in the arrow mark direction shown in

the illustration.

2. REMOVE LH SEAT REAR SEAT RECLINING COVER

Remove the 2 screws.

R ...