Toyota Sienna Service Manual: Speedometer Malfunction

DESCRIPTION

Factors that affect the indicated vehicle speed include tire size, tire inflation, and tire wear. The speed indicated on the speedometer has an allowable margin of error. This can be tested using a speedometer tester (calibrated chassis dynamometer). For details about testing and the margin of error, see the reference chart.

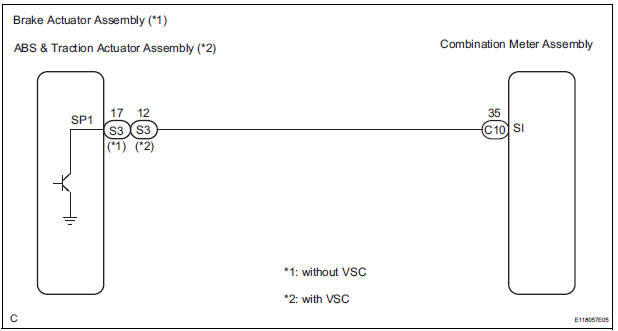

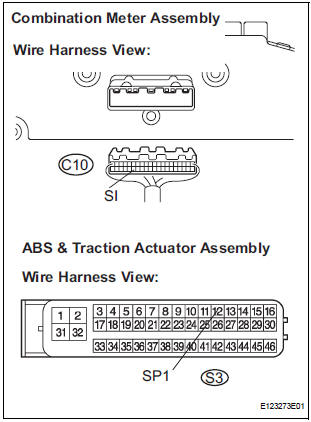

WIRING DIAGRAM

INSPECTION PROCEDURE

NOTICE: If the vehicle speed is outside the allowable range when tested, perform the following procedure.

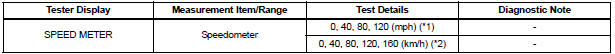

1 PERFORM ACTIVE TEST BY INTELLIGENT TESTER

- Connect the tester to the DLC3.

- Turn the ignition switch to the ON position.

- Turn the tester ON.

- Enter the following menus: DIAGNOSIS / OBD/MOBD / METER / ACTIVE TEST

- Check the operation by referring to the values in the table below.

METER:

*1: for U.S.A.

*2: Except for U.S.A.

OK: Needle indication is within the allowable range.

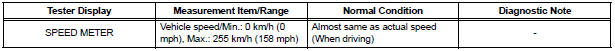

2 READ VALUE OF INTELLIGENT TESTER

- Connect the intelligent tester to the DLC3.

- Turn the ignition switch to the ON position.

- Turn the tester ON.

- Enter the following menus: DIAGNOSIS / OBD/MOBD / METER / DATA LIST.

- Check the values by referring to the values in the table below.

METER:

OK: Vehicle speed displayed on the tester is almost the same as the actual vehicle speed measured using a speedometer tester (calibrated chassis dynamometer).

REPLACE COMBINATION METER ASSEMBLY

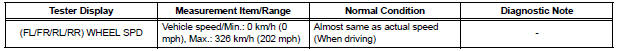

3 READ VALUE OF INTELLIGENT TESTER

- Connect the intelligent tester to the DLC3.

- Turn the ignition switch to the ON position.

- Turn the tester ON.

- Enter the following menus: DIAGNOSIS / ABS/TRAC/ VSC / DATA LIST.

- Check the values by referring to the values in the table below.

ABS/TRAC/VSC:

OK: Vehicle speed displayed on the tester is almost the same as the actual vehicle speed measured using a speedometer tester (calibrated chassis dynamometer).

4 INSPECT COMBINATION METER ASSEMBLY

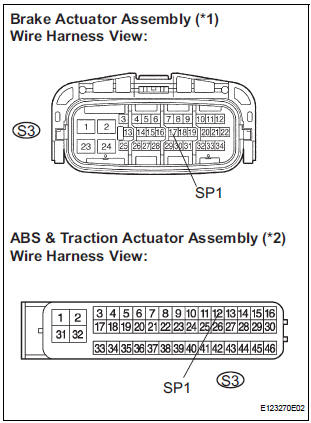

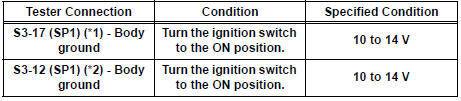

- Disconnect the S3 connector.

- Measure the voltage according to the value(s) in the table below.

Standard voltage

*1: without VSC

*2: with VSC

Result

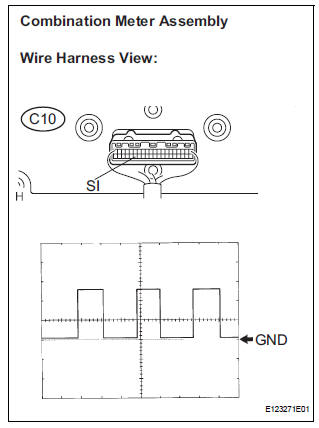

5 INSPECT COMBINATION METER ASSEMBLY

- Check the input signal waveform.

- Remove the combination meter assembly with connector(s) still connected.

- Connect the oscilloscope to terminal C10-35 (SI) and body ground.

- Turn the wheel slowly.

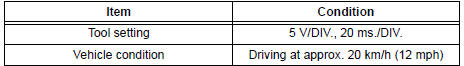

- Check the signal waveform according to the condition(s) in the table below.

OK: The waveform is displayed as shown in the illustration.

HINT: As the vehicle speed increases, the cycle of the signal waveform narrows.

Result

REPLACE COMBINATION METER ASSEMBLY

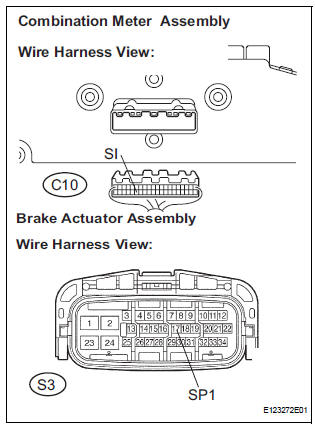

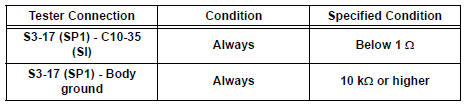

6 CHECK HARNESS AND CONNECTOR (COMBINATION METER - BRAKE ACTUATOR ASSEMBLY)

- Disconnect the S3 and C10 connectors.

- Measure the resistance according to the value(s) in the table below.

Standard resistance

REPLACE COMBINATION METER ASSEMBLY

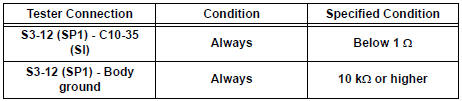

7 CHECK HARNESS AND CONNECTOR (COMBINATION METER - ABS & TRACTION ACTUATOR ASSEMBLY)

- Disconnect the S3 and C10 connectors.

- Measure the resistance according to the value(s) in the table below.

Standard resistance

REPLACE COMBINATION METER ASSEMBLY

Entire Combination Meter does not Operate

Entire Combination Meter does not Operate

DESCRIPTION

This is the power source circuit to operate the combination meter assembly.

WIRING DIAGRAM

INSPECTION PROCEDURE

1 INSPECT COMBINATION METER ASSEMBLY

Disconnect the C10 conn ...

Tachometer Malfunction

Tachometer Malfunction

DESCRIPTION

The meter CPU receives the engine revolution signal from the ECM via the

direct lines. The meter CPU

displays engine revolution data that is calculated based on the data received

fro ...

Other materials:

Crankshaft Position Sensor "A" Circuit

DTC P0335 Crankshaft Position Sensor "A" Circuit

DTC P0339 Crankshaft Position Sensor "A" Circuit Intermittent

DESCRIPTION

The Crankshaft Position (CKP) sensor system consists of a CKP sensor plate

and a pickup coil. The

sensor plate has 34 teeth and is installed on the cra ...

Wireless remote control/

electronic key battery

Replace the battery with a new one if it is depleted.

You will need the following items:

Flathead screwdriver

Lithium battery CR2032

Replacing the battery

Vehicles without a smart key system

Remove the cover using a coin

protected with tape etc.

Remove the deplete ...

Washer Signal Circuit

DESCRIPTION

The distance control ECU detects washer operation. The cruise control will be

cancelled by the distance

control ECU if the windshield wipers operate in the HI or LO mode. By detecting

washer operation, the

distance control ECU allows the cruise control to continue even when the

...