Toyota Sienna Service Manual: Terminals of ECU

1. CHECK TRANSPONDER KEY AMPLIFIER

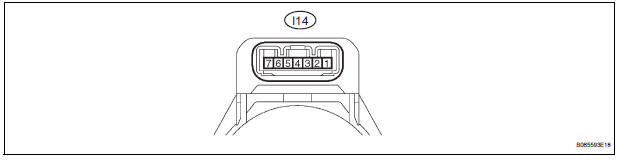

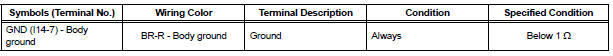

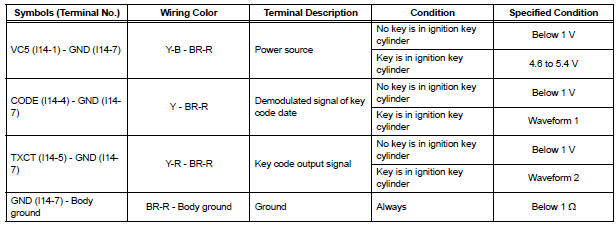

- Disconnect the I14 amplifier connector and measure the resistance between the terminal of the wire harness side connector and body ground.

If the result is not as specified, there may be a malfunction on the wire harness side.

- Reconnect the I14 amplifier connector and measure the resistance and voltage of each terminal of the connector

If the result is not as specified, the amplifier may have a malfunction.

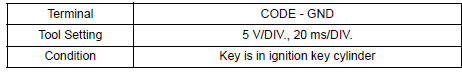

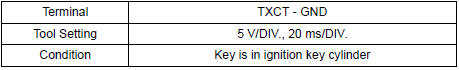

- Inspect using an oscilloscope.

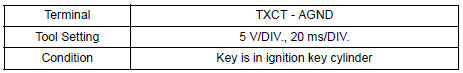

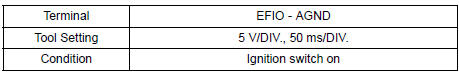

- Waveform 1 (Reference):

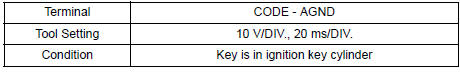

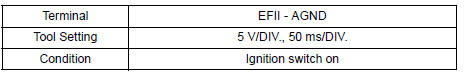

- Waveform 2 (Reference):

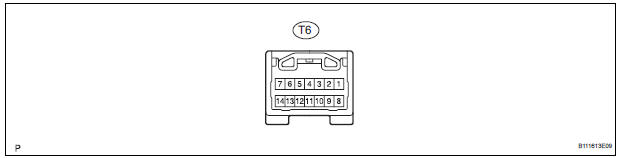

2. CHECK TRANSPONDER KEY ECU ASSEMBLY

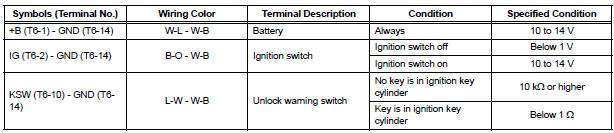

- Disconnect the T6 ECU connector and measure the resistance and voltage between each terminal of the wire harness side connector

If the result is not as specified, there may be a malfunction on the wire harness side.

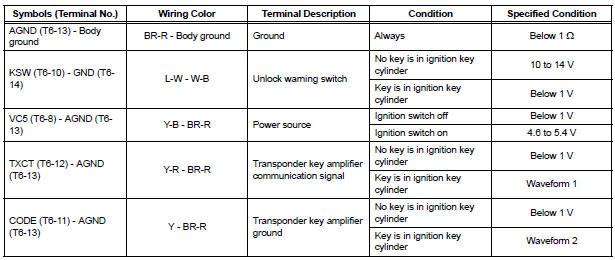

- Reconnect the T9 ECU connector and measure the voltage of each terminal of the connector.

If the result is not as specified, the ECU may have a malfunction.

- Inspect using an oscilloscope.

- Wave form 1 (Reference):

- Wave form 2 (Reference):

- Wave form 3 (Reference):

- Wave form 4 (Reference):

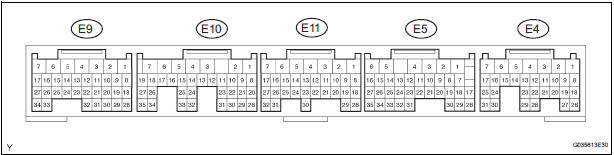

3. CHECK ECM

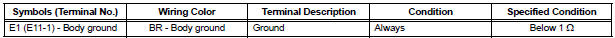

- Disconnect the E11 ECM connector and measure the resistance between the terminal of the wire harness side connector and body ground.

If the result is not as specified, there may be a malfunction on the wire harness side.

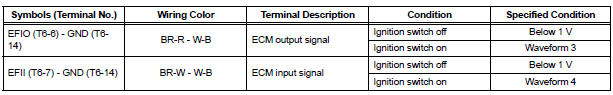

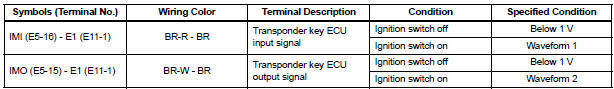

- Reconnect the E11 ECM. Measure the voltage between each terminal of the connector according to the value(s) in the table below.

If the result is not as specified, there may be a malfunction on the wire harness side.

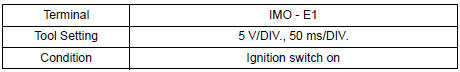

- Inspect using an oscilloscope.

- Waveform 1 (Reference):

- Waveform 2 (Reference):

Problem symptoms table

Problem symptoms table

ENGINE IMMOBILISER SYSTEM

...

Diagnosis system

Diagnosis system

1. CHECK DLC3

The vehicle's ECU uses ISO 15765-4 for

communication protocol. The terminal arrangement

of the DLC3 complies with SAE J1962 and matches

the ISO 15765-4 format.

...

Other materials:

Problem symptoms table

POWER WINDOW CONTROL SYSTEM (W/O JAM PROTECTION)

Symptom

Suspected Area

All power windows do not operate

PWR fuse

Power window relay (Marking: P/W)

Ignition switch

Power window regulator master switch

Power window regulator motor assembly

...

Releasing and stowing the seat belt (for the third center seat)

To release plate “B”, press the

release button on buckle “B”.

To release plate “A”, insert the

key or plate “B” into

the hole on buckle “A”.

Retract the belt slowly when

releasing and stowing the seat

belt.

Insert the seat belt plates into

...

Mirror Switch Circuit

DESCRIPTION

A switch signal of the outer mirror switch is transmitted to the

selected outer mirror control ECU by way

of the body ECU. Then, the outer mirror control ECU activates the mirror

motor to move the mirror UP,

DOWN, RIGHT and LEFT in response to the inputs.

HINT:

Th ...