Toyota Sienna Service Manual: Throttle / Pedal Position Sensor / Switch "A" Circuit Range / Performance Problem

DTC P0121 Throttle / Pedal Position Sensor / Switch "A" Circuit Range / Performance Problem

HINT: This DTC relates to the Throttle Position (TP) sensor.

DESCRIPTION Refer to DTC P0120

|

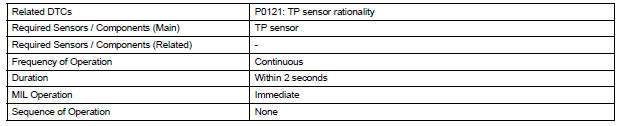

DTC No. |

DTC Detection Condition |

Trouble Area |

|

P0121 |

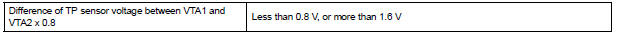

Difference between VTA1 and VTA2 voltages less than 0.8 V, or more than 1.6 V for 2 seconds (1 trip detection logic) | TP sensor (built into throttle body) |

MONITOR DESCRIPTION

The ECM uses the TP sensor to monitor the throttle valve opening angle.

This sensor transmits two signals: VTA1 and VTA2. VTA1 is used to detect the throttle opening angle and VTA2 is used to detect malfunctions in VTA1. The ECM performs several checks to confirm the proper operation of the TP sensor and VTA1.

For each throttle opening angle, a specific voltage difference is expected between the outputs of VTA1 and VTA2. If the voltage output difference between the two signals deviates from the normal operating range, the ECM interprets this as a malfunction of the TP sensor. The ECM illuminates the MIL and sets the DTC.

If the malfunction is not repaired successfully, the DTC is set 2 seconds after the engine is next started.

MONITOR STRATEGY

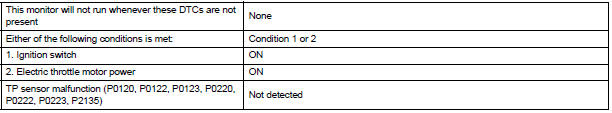

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

FAIL-SAFE

When this DTC, as well as other DTCs relating to ETCS (Electronic Throttle Control System) malfunctions, is set, the ECM enters fail-safe mode. During fail-safe mode, the ECM cuts the current to the throttle actuator off, and the throttle valve is returned to a 6.5 throttle angle by the return spring. The ECM then adjusts the engine output by controlling the fuel injection (intermittent fuel-cut) and ignition timing, in accordance with the accelerator pedal opening angle, to allow the vehicle to continue at a minimal speed. If the accelerator pedal is depressed slowly, the vehicle can be driven slowly.

Fail-safe mode continues until a pass condition is detected, and the ignition switch is then turned off.

INSPECTION PROCEDURE

HINT: Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data can be helpful in determining whether the vehicle was running or stopped, whether the engine was warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the time of a malfunction.

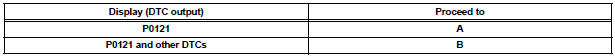

1 CHECK ANY OTHER DTC OUTPUT (IN ADDITION TO DTC P0121)

- Connect the intelligent tester to the DLC3.

- Turn the ignition switch to the ON position.

- Turn the tester ON.

- Enter the following menus: DIAGNOSIS / ENHANCED OBD II / DTC INFO / CURRENT CODES.

- Read the DTC

Result

HINT: If any DTCs other than P0121 are output, troubleshoot those DTCs first.

REPLACE THROTTLE BODY

Throttle / Pedal Position Sensor / Switch "A/B"

Circuit

Throttle / Pedal Position Sensor / Switch "A/B"

Circuit

DTC P0120 Throttle / Pedal Position Sensor / Switch "A"

Circuit

DTC P0122 Throttle / Pedal Position Sensor / Switch "A"

Circuit Low Input

DTC P0123 Throttle / Pedal Position Se ...

Insufficient Coolant Temperature for Closed

Loop Fuel Control

Insufficient Coolant Temperature for Closed

Loop Fuel Control

DTC P0125 Insufficient Coolant Temperature for Closed

Loop Fuel Control

DESCRIPTION

Refer to DTC P0115

DTC No.

DTC Detection Condition

Trouble Area

P0125

E ...

Other materials:

Mechanical system tests

1. PERFORM MECHANICAL SYSTEM TESTS

(a) Measure the stall speed.

The object of this test is to check the overall

performance of the transaxle and engine by

measuring the stall speeds in the D position.

NOTICE:

Driving test should be done on a paved road

(a nonskid road).

Per ...

Center Airbag Sensor Assembly Malfunction

DTC B1100/31 Center Airbag Sensor Assembly Malfunction

DESCRIPTION

The center airbag sensor assembly consists of the center airbag sensor

assembly, safing sensor, drive

circuit, diagnosis circuit and ignition control, etc.

It receives signals from the airbag sensor, judges whether or not the ...

U151f automatic transaxle

SST

RECOMMENDED TOOLS

EQUIPMENT

LUBRICANT

SSM

...