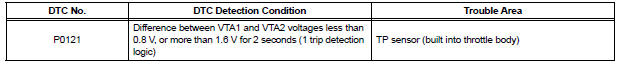

Toyota Sienna Service Manual: Throttle / Pedal Position Sensor / Switch "A" Circuit Range / Performance Problem

HINT: This DTC relates to the Throttle Position (TP) sensor.

DESCRIPTION

Refer to DTC P0120 (See page ES-145).

MONITOR DESCRIPTION

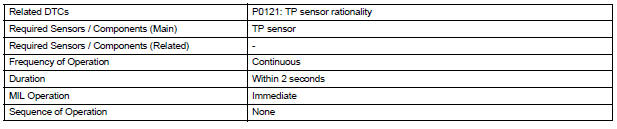

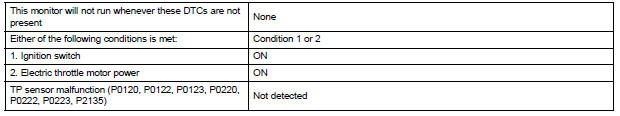

The ECM uses the TP sensor to monitor the throttle valve opening angle.

This sensor transmits two signals: VTA1 and VTA2. VTA1 is used to detect the throttle opening angle and VTA2 is used to detect malfunctions in VTA1. The ECM performs several checks to confirm the proper operation of the TP sensor and VTA1.

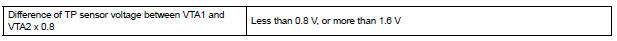

For each throttle opening angle, a specific voltage difference is expected between the outputs of VTA1 and VTA2. If the voltage output difference between the two signals deviates from the normal operating range, the ECM interprets this as a malfunction of the TP sensor. The ECM illuminates the MIL and sets the DTC.

If the malfunction is not repaired successfully, the DTC is set 2 seconds after the engine is next started.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

FAIL-SAFE

When this DTC, as well as other DTCs relating to ETCS (Electronic Throttle Control System) malfunctions, is set, the ECM enters fail-safe mode. During fail-safe mode, the ECM cuts the current to the throttle actuator off, and the throttle valve is returned to a 6.5° throttle angle by the return spring. The ECM then adjusts the engine output by controlling the fuel injection (intermittent fuel-cut) and ignition timing, in accordance with the accelerator pedal opening angle, to allow the vehicle to continue at a minimal speed. If the accelerator pedal is depressed slowly, the vehicle can be driven slowly.

Fail-safe mode continues until a pass condition is detected, and the ignition switch is then turned off.

INSPECTION PROCEDURE

HINT: Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data can be helpful in determining whether the vehicle was running or stopped, whether the engine was warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the time of a malfunction.

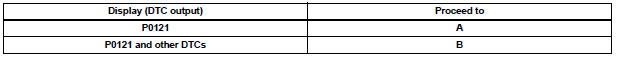

1 CHECK ANY OTHER DTC OUTPUT (IN ADDITION TO DTC P0121)

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position.

(c) Turn the tester ON.

(d) Enter the following menus: DIAGNOSIS / ENHANCED OBD II / DTC INFO / CURRENT CODES.

(e) Read the DTC.

Result

HINT: If any DTCs other than P0121 are output, troubleshoot those DTCs first.

REPLACE THROTTLE BODY

Throttle / Pedal Position Sensor / Switch "A"

Throttle / Pedal Position Sensor / Switch "A"

HINT:

These DTCs relate to the Throttle Position (TP) sensor.

DESCRIPTION

HINT:

This ETC (Electrical Throttle Control System) does not use a throttle cable.

The Throttle Position (TP) senso ...

Insufficient Coolant Temperature for Closed Loop Fuel Control

Insufficient Coolant Temperature for Closed Loop Fuel Control

DESCRIPTION

Refer to DTC P0115 (See page ES-133).

MONITOR DESCRIPTION

The resistance of the ECT sensor varies in proportion to the actual ECT. The

ECM supplies a constant

voltage to the ...

Other materials:

Air Mix Damper Control Servo Motor Circuit (Driver Side)

DESCRIPTION

The air mix control servo motor (air mix damper servo sub-assembly) is

controlled by the A/C amplifier.

The air mix control servo motor moves the air mix damper by rotating (normal,

reverse) with electrical

power from the A/C amplifier.

This adjusts the mix ratio of the air t ...

Short to GND in Front Passenger Side Squib

Circuit

DTC B0107/51 Short to GND in Front Passenger Side Squib

Circuit

DESCRIPTION

The front passenger side squib circuit consists of the center airbag sensor

assembly and the front

passenger airbag assembly.

The circuit instructs the SRS to deploy when deployment conditions are met.

DTC B0107/ ...

Brake Warning Light Remains ON

DESCRIPTION

If the ECU detects a trouble, it turns on the brake warning light at the same

time of prohibiting ABS

control.

At this time, the ECU records a DTC in memory.

Connect terminals TC and CG of the DLC3 to make the brake warning light blink

and output the DTC.

WIRING DIAGRAM

...