Toyota Sienna Service Manual: Vehicle Speed Signal Circuit between Radio Receiver and Combination Meter

DESCRIPTION This circuit is necessary for the ASL (Auto Sound Leveliser) built into the radio receiver.

Speed signals are received from the combination meter and used for the ASL.

The ASL function automatically adjusts the sound data in order to enable hearing the clear audio sound even when vehicle noise increases (as vehicle noise increases, the volume is turned up etc.).

HINT:

- A voltage of 12 V or 5 V is output from each ECU and then input to the combination meter. The signal is changed to a pulse signal at the transistor in the combination meter. Each ECU controls the respective system based on the pulse signal.

- If a short occurs in an ECU, all systems in the diagram below will not operate normally.

WIRING DIAGRAM

INSPECTION PROCEDURE

1 CHECK OPERATION OF SPEEDOMETER

- Drive the vehicle and check if the function of the speedometer on the combination meter is normal.

OK: Actual vehicle speed and the speed indicated on the speedometer are the same.

HINT: the vehicle speed sensor is functioning normally when the indication on the speedometer is normal.

2 INSPECT RADIO RECEIVER

- Disconnect the radio receiver connector.

- Measure the voltage.

- Jack up either one of the drive wheels.

- Move the shift lever to the neutral position.

- Turn the ignition switch to the ON position.

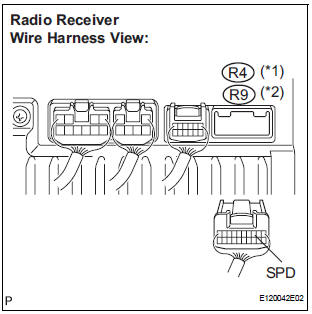

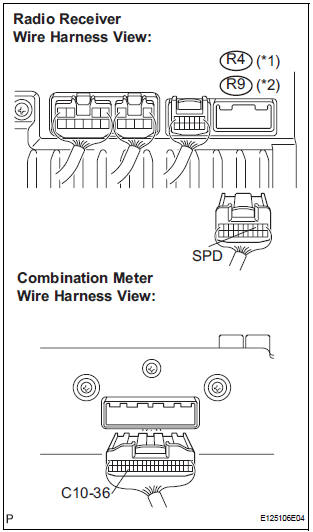

*1: 6 Speaker without Rear Seat Entertainment System.

*2: 6 Speaker with Rear Seat Entertainment System.

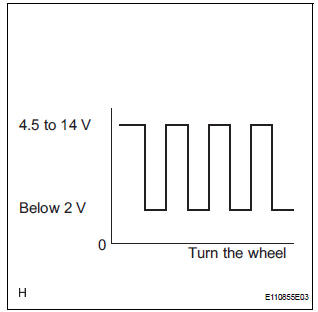

- Measure the voltage between terminal SPD of the radio receiver and body ground when the drive wheels are turned slowly.

OK: Voltage pulses as shown in the illustration.

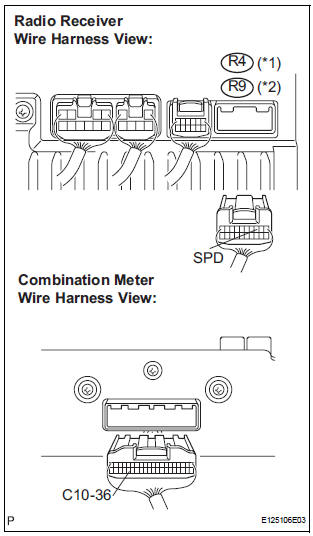

3 CHECK HARNESS AND CONNECTOR (COMBINATION METER - RADIO RECEIVER)

- Disconnect the radio receiver connector and combination meter connector.

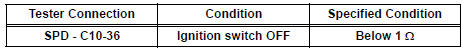

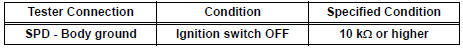

- Measure the resistance according to the value(s) in the table below.

Standard resistance

*1: 6 Speaker without Rear Seat Entertainment System.

*2: 6 Speaker with Rear Seat Entertainment System.

4 CHECK HARNESS AND CONNECTOR

- Disconnect the radio receiver connector and combination meter connector.

- Measure the resistance according to the value(s) in the table below.

Standard resistance

HINT: If the resistance between terminal SPD and body ground is less than 10 kΩ, there may be a short in a wire harness, connector, or an ECU that is connected to the SPD signal wire.

*1: 6 Speaker without Rear Seat Entertainment System.

*2: 6 Speaker with Rear Seat Entertainment System.

REPLACE COMBINATION METER

Poor Sound Quality in All Modes (Low Volume)

Poor Sound Quality in All Modes (Low Volume)

INSPECTION PROCEDURE

1 CHECK AUDIO SETTINGS

Set "BASS", "MID", and "TREB" to the initial values and

check that sound is normal.

OK:

Malfunction disappears.

2 ...

Steering Pad Switch Circuit

Steering Pad Switch Circuit

DESCRIPTION

This circuit sends an operation signal from the steering pad switch to the

radio receiver.

If there is an open in the circuit, the audio system cannot be operated using

the steerin ...

Other materials:

Installation

1. Install air fuel ratio sensor (for bank 2

sensor 1)

(a) Using SST, install the sensor to the exhaust

manifold LH.

SST 09224-00010

Torque: 40 N*m (408 kgf*cm, 30 ft.*lbf) for use

with SST

44 N*m (449 kgf*cm, 32 ft.*lbf) for use

without SST

HINT:

Use a torque wrench with a fulcrum ...

Installation

1. INSTALL COMBINATION METER ASSEMBLY

Connect the connectors.

Install the combination meter assembly with the 4

screws.

2. INSTALL INSTRUMENT CLUSTER FINISH PANEL SUB-ASSEMBLY

Install the instrument cluster finish panel subassembly

with the 4 clips.

3. C ...

Pressure Control Solenoid "C" Electrical (Shift

Solenoid Valve SL3)

DESCRIPTION

Shifting from 1st to 5th is performed in combination with "ON" and "OFF"

operation of the shift solenoid

valves SL1, SL2, SL3, S4 and SR which are controlled by the ECM. If an open or

short circuit occurs in

either of the shift solenoid valves, the ECM controls ...