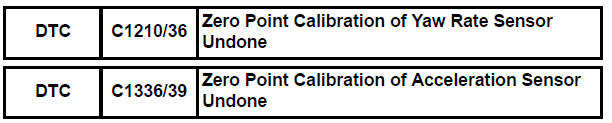

Toyota Sienna Service Manual: Zero Point Calibration of Yaw Rate Sensor Undone

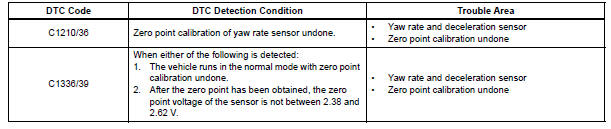

DESCRIPTION

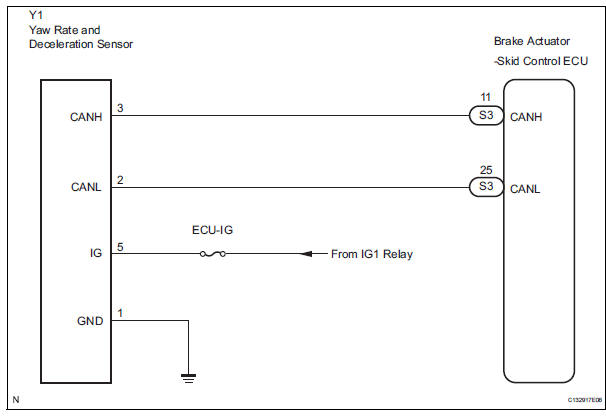

The skid control ECU receives signals from the yaw rate sensor via CAN communication system.

Yaw rate sensor has the built-in deceleration sensor.

If there is trouble in the bus lines between the yaw rate and deceleration sensor and CAN communication system, the DTC U0123/62 (yaw rate sensor communication trouble) and U0124/95 (deceleration sensor communication trouble) are output.

The DTC is also output when the calibration has not been completed.

WIRING DIAGRAM

INSPECTION PROCEDURE

HINT: When U0073/94, U0100/65, U0123/62, U0124/95 or U0126/63 are output accompanied with C1210/36 or C1336/39, inspect and repair the trouble areas indicated by U0073/94, U0100/65, U0123/62, U0124/95 or U0126/63 first.

1 PERFORM ZERO POINT CALIBRATION OF YAW RATE AND DECELERATION SENSOR

(a) Perform the zero point calibration of the yaw rate and deceleration sensor (See page BC-70).

2 RECONFIRM DTC

(a) Clear the DTCs (See page BC-82).

(b) Turn the ignition switch to the ON position.

(c) Are the same DTCs recorded (See page BC-82).

Result

3 CHECK YAW RATE AND DECELERATION SENSOR INSTALLATION

(a) Check that the yaw rate and deceleration sensor has been installed properly (See page BC-197).

NOTICE: When replacing the yaw rate and deceleration sensor, perform zero point calibration (See page BC- 70).

REPLACE YAW RATE AND DECELERATION SENSOR

ECM Communication Circuit Malfunction

ECM Communication Circuit Malfunction

DTC C1203/53 ECM Communication Circuit Malfunction

DESCRIPTION

The circuit is used to send TRAC and VSC control information from the skid

control ECU to the ECM, and

engine control information fr ...

SM Solenoid Circuit

SM Solenoid Circuit

DTC C1225/25 SM Solenoid Circuit

DESCRIPTION

This solenoid turns on when receiving signals the ECU and controls the

pressure acting on the wheel

cylinders to control the braking force.

WIRIN ...

Other materials:

Initialization

Items to initialize

The following items must be initialized for normal system operation

after such cases as the battery being reconnected, or maintenance

being performed on the vehicle.

Item

When to initialize

Power sliding door

(if equipped)

After reconnecting o ...

Installation

1. INSTALL AIR CONDITIONING BLOWER ASSEMBLY

(a) Install the air conditioning blower assembly with the

3 bolts.

Torque: 5.4 N*m (55 kgf*cm, 48 in.*lbf)

NOTICE:

Tighten the bolts in the order shown in the

illustration to install the air conditioning blower

assembly.

2. INSTALL AIR CONDITIO ...

Map Disc Read Error

DTC 58-42 Map Disc Read Error

DTC 80-42 Map Disc Read Error

DESCRIPTION

DTC No.

DTC Detection Condition

Trouble Area

58-42

Player error

Scratches or dirt on the disc

Access to an invalid address due to software error

...